Top convection radiation laminated glass autoclave

A technology of laminated glass and autoclave, applied in the field of top convection radiation laminated glass autoclave, to achieve the effect of temperature balance and improvement of heat treatment quality and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

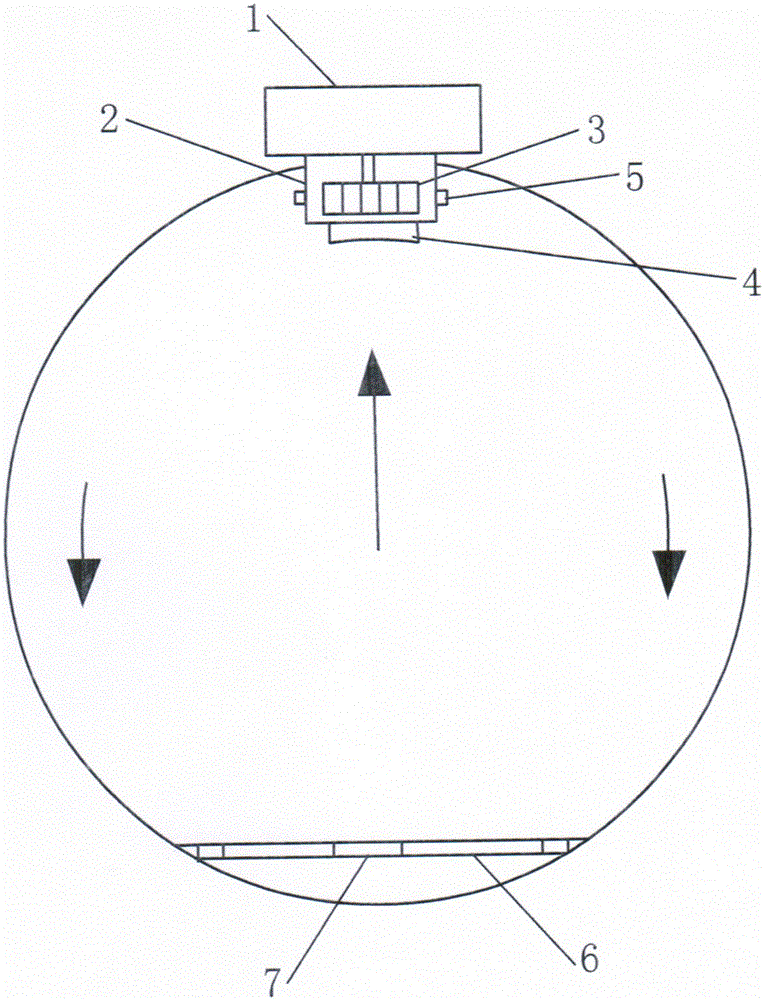

[0010] As shown in the figure: a fan motor 1 is installed on the upper part of the autoclave, and a wind wheel 3 is installed on the shaft of the fan motor. Air hole 5, air suction hole 4 is provided at the bottom of the fan casing, and air distribution plate 6 is installed at the bottom of the autoclave casing, and air return hole 7 is provided on the air distribution plate.

[0011] Working process of the present invention:

[0012] When the autoclave heats the laminated glass, the fan airflow blows downward from both sides of the autoclave shell, and the blown wind passes through the air distribution plate, flows upward from the return air hole, and is sucked back through the air suction hole. In the fan casing, with the continuous circulation of the airflow, it acts as a temperature disturbance, so that the temperature in the autoclave is balanced. When the heating of the autoclave is stopped, the circulating flow of the airflow can cool down and balance the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com