Large-area concrete-pavement trowelling machine

A troweling machine and large-area technology, which is applied in roads, buildings, building structures, etc., can solve problems such as poor work efficiency and large dependence on labor, and achieve the effects of easy use, improved work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

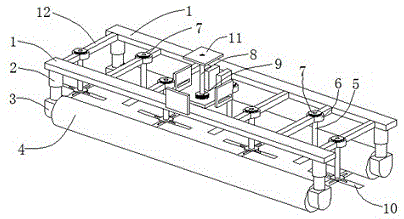

[0012] see figure 1 , the specific embodiment is realized by adopting the following technical scheme, which includes two support plates 1 arranged in parallel, telescopic cylinders 2 are respectively installed at the two ends of the bottom of the support plates 1, and the piston shaft ends of the telescopic cylinders 2 are equipped with Roller base 3, a guide roller 4 is installed between the two roll bases 3 on the same support plate 1 to rotate and cooperate with it. Between the two support plates 1, there are several rotating shafts that are staggered in front, back, left, and right. 5. One end of the rotating shaft 5 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com