Odor-resistant floor drain having double turnover panels

A flap and floor drain technology, which is applied to waterway systems, drainage structures, water supply devices, etc., can solve the problems that cannot be fully opened, the service life is only a few months, and the service life is short, so as to achieve good drainage effect, simple structure, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

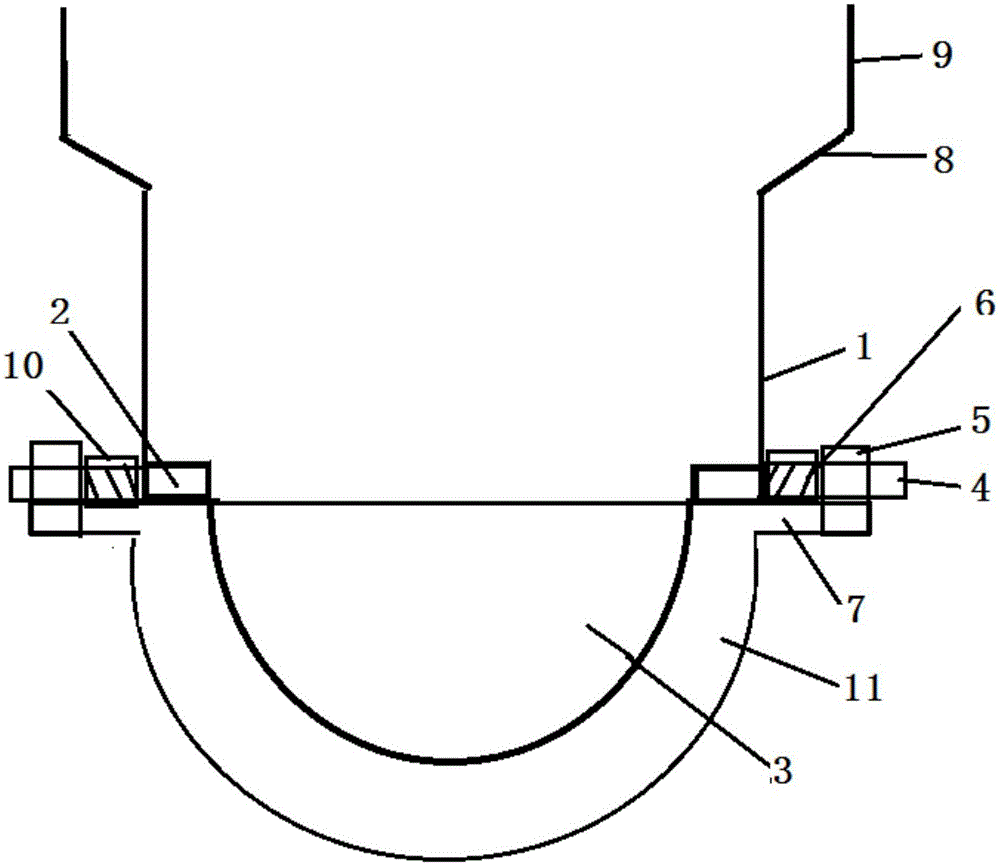

[0029] Such as figure 1 As shown, the double-flap anti-odor floor drain of the present invention includes a cylinder 1, and two rotating shafts 4 are symmetrically arranged on the outer wall of the lower end of the cylinder 1, and one end of the two rotating shafts 4 is perpendicular to the outer wall of the cylinder 1 respectively. Connection, that is, the connecting line of the two rotating shafts 4 and the diameter of the cylinder 1 are on the same straight line, and two symmetrical flaps 3 are rotatable on the rotating shaft 4, and the two flaps 3 are connected to the cylinder body. 1 The cross-sectional shape matches, one side edge of the turning plate 3 is in contact with the bottom of the cylinder body 1, and the other side of the turning plate 3 is rotatably connected with the rotating shaft 4.

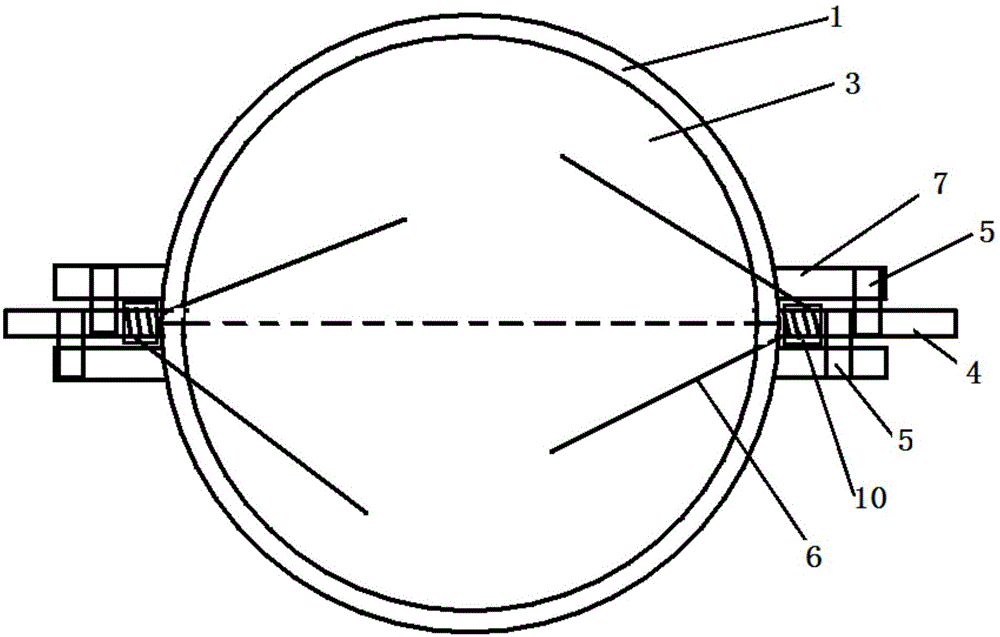

[0030] Such as figure 2 As shown, preferably, the cylinder body 1 is cylindrical, the flap 3 is a semicircle matching with the cylinder body 1, the arc edge of the flap 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com