Wall stone material for chicken farms

A technology for chicken farms and walls, applied in the field of chicken houses, can solve the problems of easy accumulation of dust on the surface, dull concrete color, time-consuming and labor-intensive, etc., to overcome the damage of the natural environment, improve the thermal insulation performance, and protect the natural environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

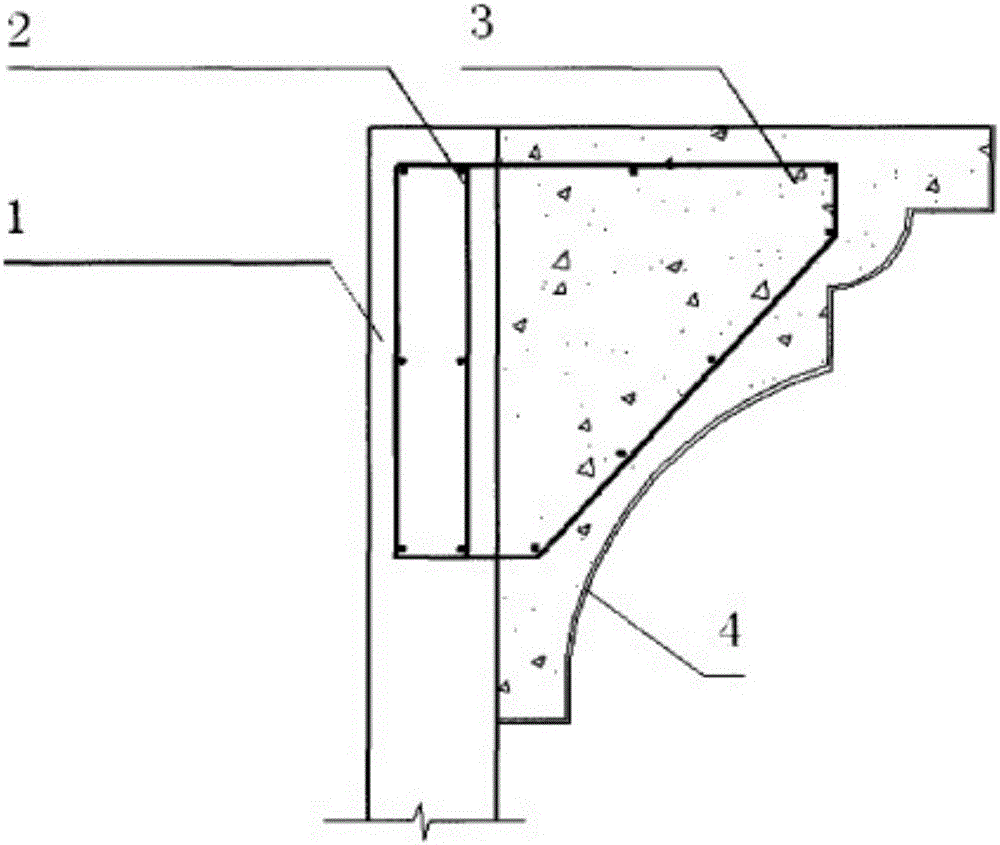

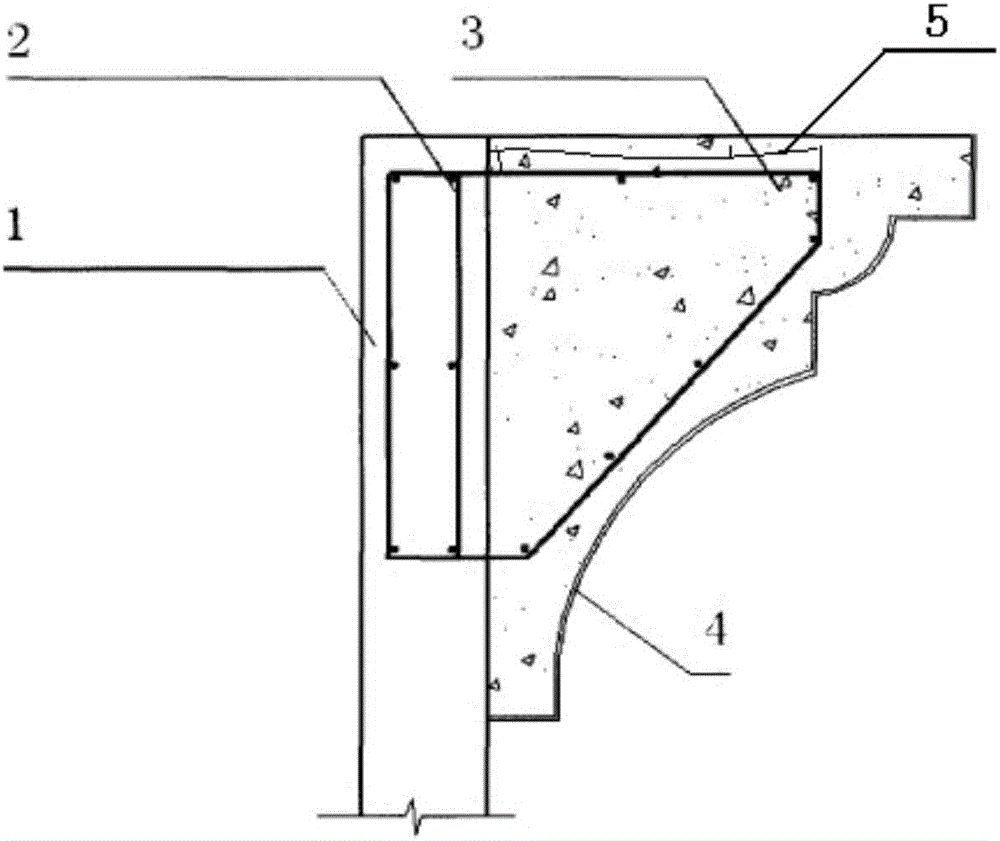

[0023] Such as figure 1 Shown is a schematic diagram of the structure of the present invention. This embodiment includes steel bars 2 and a stone-like material layer 3 for setting on the wall body 1. The stone-like material layer and the steel bars are poured together. There is also a resin layer between the decorative line and the imitation stone material layer, which can meet the fine adjustment of the position of the decorative line and facilitate the installation. The stone is installed on the outer wall of the chicken farm to achieve a good simulation texture without frequent maintenance.

[0024] The imitation stone material layer 3 of the present invention is prepared by white cement, natural granite, glue, inorganic pigments and water in a ratio of 1:1.5-2:0.0001-0.05:0.3.

[0025] The present invention is also provided with a protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com