Novel honeycomb seal rotor structure

A technology of honeycomb sealing and rotor structure, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., and can solve the problem of affecting the sealing and damping of honeycomb seals, reducing the energy dissipation of honeycomb seals, and the energy dissipation of honeycomb cores Insufficient and other problems, to achieve the effect of reducing the through effect, promoting the separation of the boundary layer, and efficiently cutting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

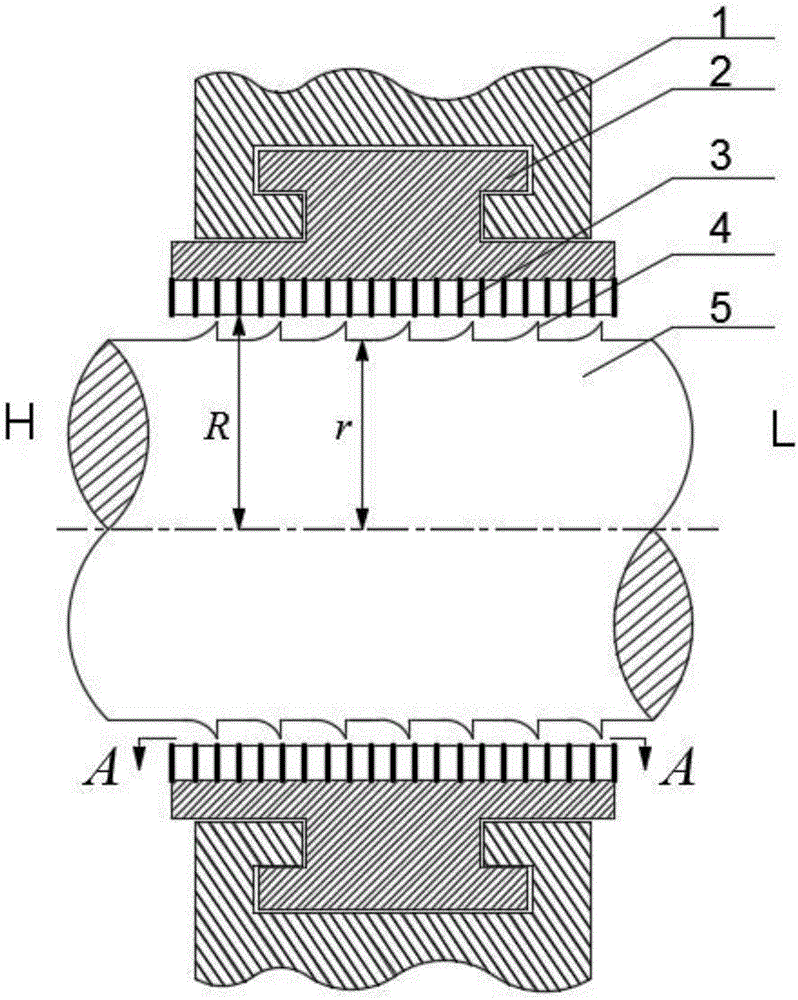

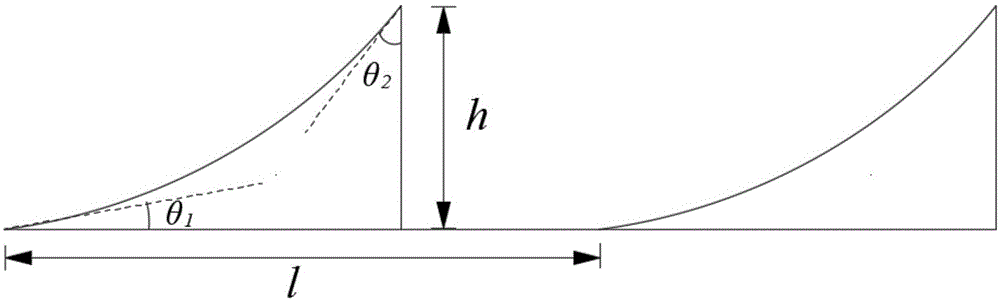

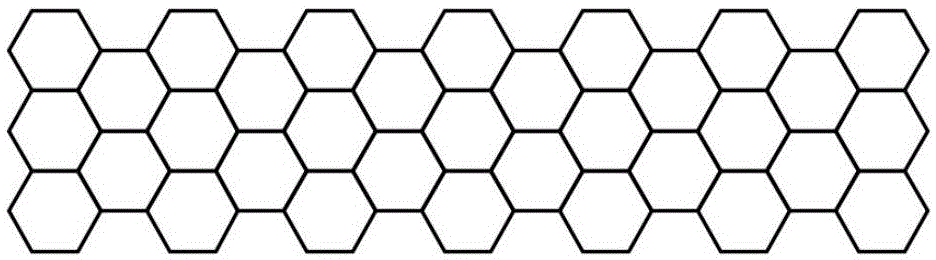

[0017] like Figure 1-Figure 3 Shown: a new type of honeycomb sealed rotor structure, including a sealing sleeve 1, a sealing body 2, an annular concave arc wedge-shaped boss 4, a honeycomb belt 3 and a rotor 5. The sealing body 2 is installed on the sealing sleeve 1 through the T-shaped groove, and the sealing body 2 is provided with a honeycomb belt 3 in the circumferential direction. The sealing sleeve 1, the sealing body 2 and the honeycomb belt 3 all belong to the stator components. The rotor 5 is located in the annular cavity formed by the honeycomb belt 3 . The rotor 5 is axially provided with a plurality of groups of annular concave arc wedge-shaped bosses 4 on its circumferential surface. The included angle θ between the arc surface of the annular concave arc wedge-shaped boss 4 and the surface of the rotor 5 1 =15°, the included angle θ with the vertical surface of the boss 2 =30°, the radial height h of the annular concave arc wedge-shaped bosses is 0.6 times th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com