Method for measuring three-dimensional deformation of cross section of underground cavity

A technology for underground caverns and three-dimensional deformation, which is applied in the direction of measuring devices and instruments, and can solve the problem of inability to accurately measure the three-dimensional deformation of the cross-section of underground caverns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

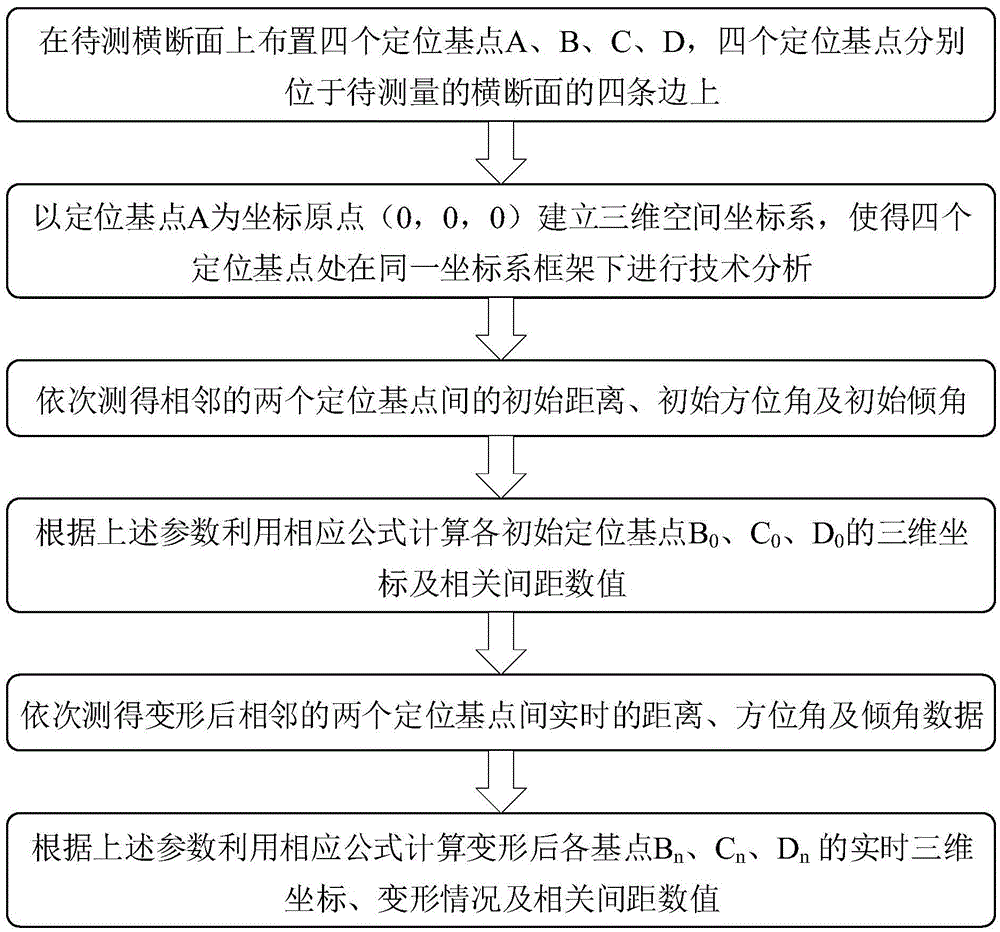

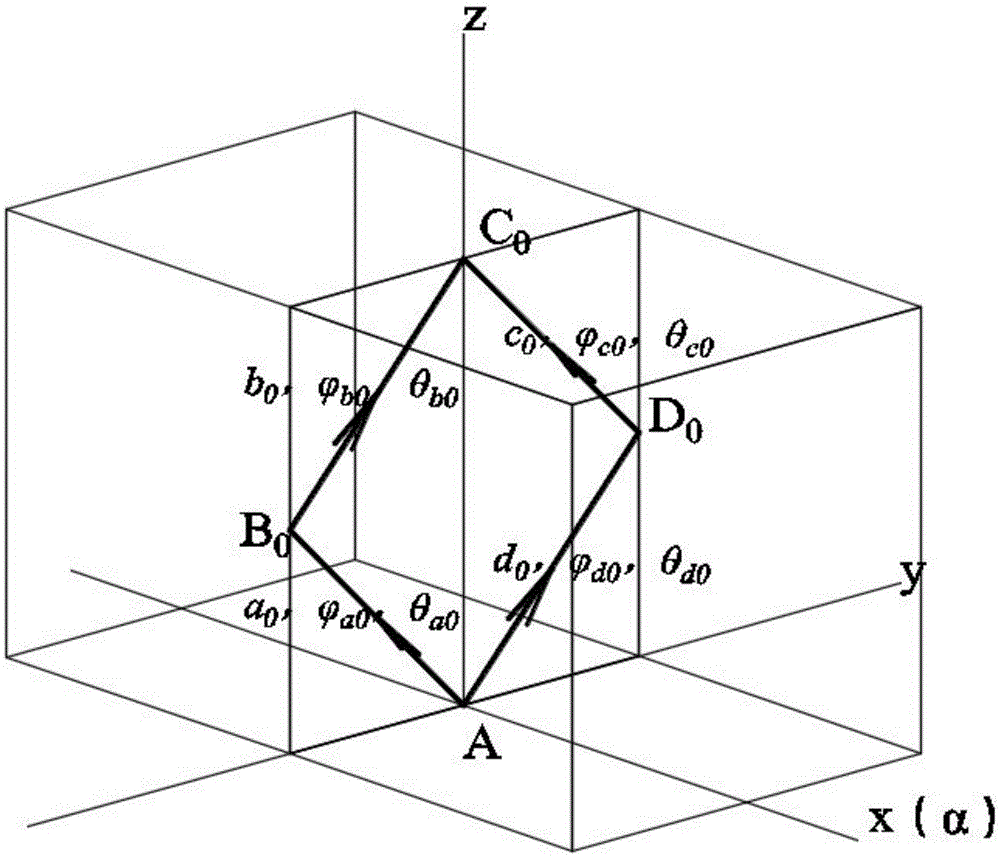

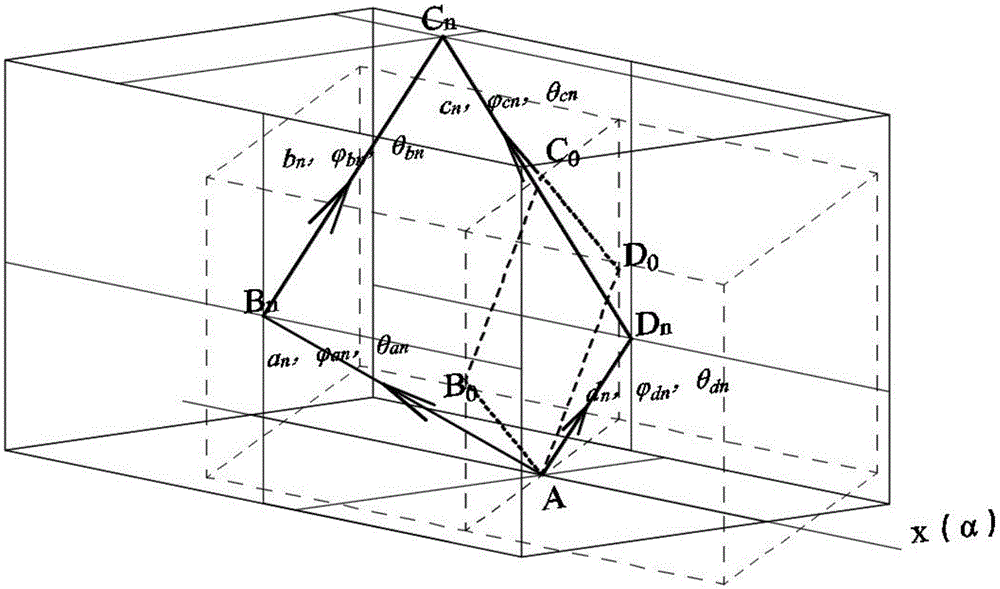

[0075] Such as figure 1 As shown, the measurement method of the three-dimensional deformation of the underground cavern cross section of the present invention comprises the following steps:

[0076] 1. According to the actual geological situation and construction conditions of the underground project, determine the cross-section of the underground cavern that needs to be monitored for three-dimensional deformation. According to the accuracy requirements and testing needs, one or more cross-sections to be measured can be arranged. Four positioning base points A, B, C, D, and the four positioning base points are not at the midpoint of each side, and this technical scheme can still be carried out. It is not limited to be at the midpoint position, but being at the midpoint position of each side has certain favorable conditions for measurement. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com