Service life tester of value execution apparatus

A technology for valve execution and life testing, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems of low back pressure stability, low precision, and unconvincing test results, etc. , to achieve the effect of optimized structural design calculation, fast and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

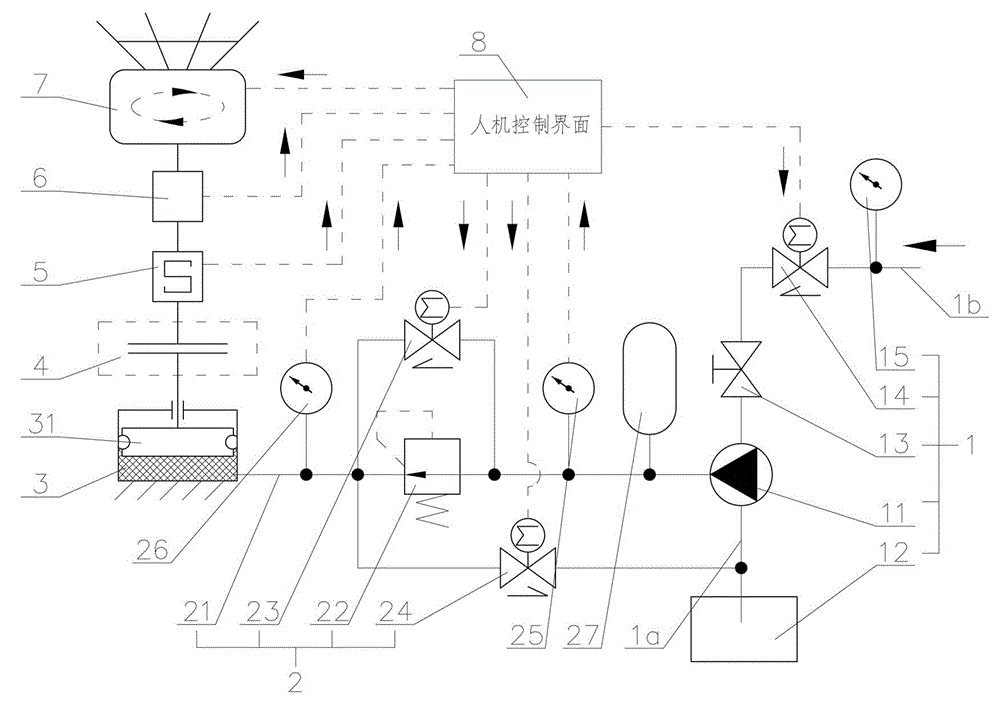

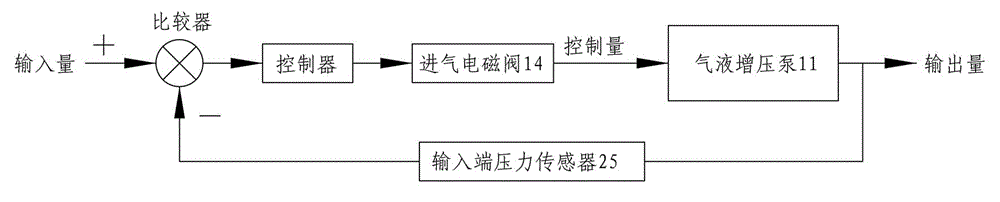

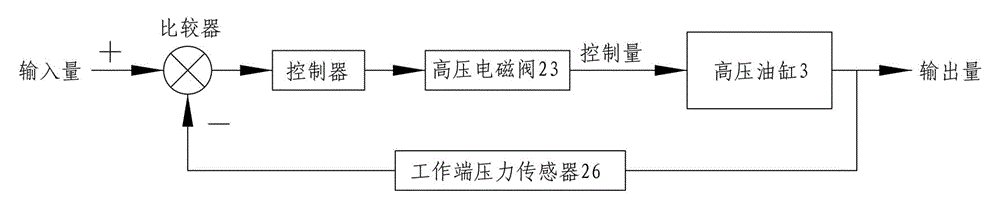

[0018] Such as figure 1 , 2 , 3 shows a specific embodiment of the life testing machine of the valve actuator of the present invention. This embodiment includes booster component 1, hydraulic component 2, high-pressure cylinder 3, friction clutch disc load torque device 4, dynamic torque sensor 5 and angle encoder 6, booster component 1, hydraulic component 2, high-pressure cylinder 3, friction clutch The disc load torque device 4, the dynamic torque sensor 5 and the angle encoder 6 are connected sequentially, the angle encoder 6 is connected to the valve actuator 7 to be detected, the booster assembly 1 pressurizes the hydraulic oil, and the hydraulic oil is sent to the high-pressure cylinder 3 through the hydraulic assembly 2 Perform pressure output and control the pressure; the high-pressure oil cylinder 3 is provided with an oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com