A life testing machine for a valve actuator

A technology for valve execution and life testing, which is applied in the direction of measuring devices, testing of mechanical components, and testing of machine/structural components, etc. It can solve problems such as low precision, low back pressure stability, and large errors, and achieve fast and flexible Adjust and optimize the effect of structural design calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

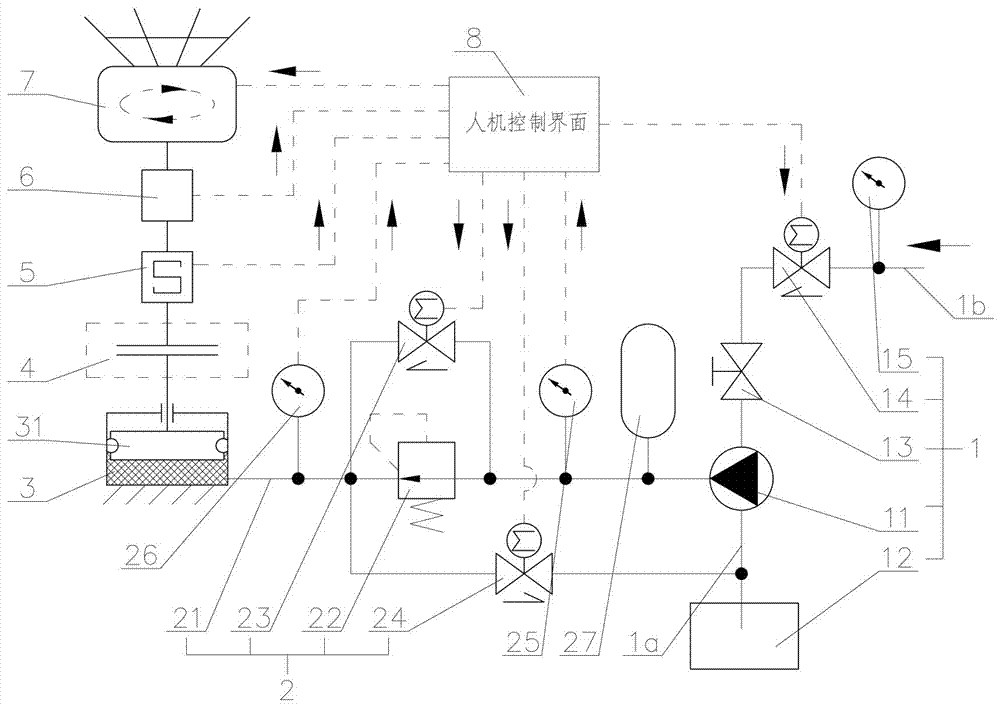

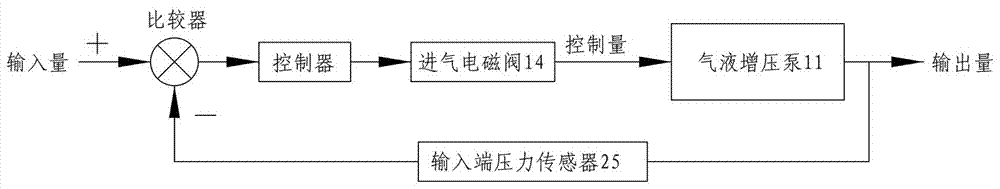

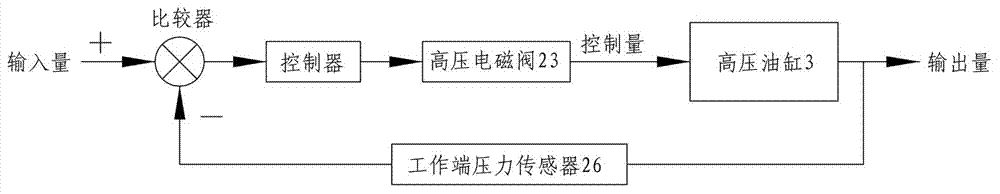

[0018] Such as figure 1 , 2 , 3 shows a specific embodiment of the life testing machine of the valve actuator of the present invention. This embodiment includes booster component 1, hydraulic component 2, high-pressure cylinder 3, friction clutch disc load torque device 4, dynamic torque sensor 5 and angle encoder 6, booster component 1, hydraulic component 2, high-pressure cylinder 3, friction clutch The disc load torque device 4, the dynamic torque sensor 5 and the angle encoder 6 are connected sequentially, the angle encoder 6 is connected to the valve actuator 7 to be detected, the booster assembly 1 pressurizes the hydraulic oil, and the hydraulic oil is sent to the high-pressure cylinder 3 through the hydraulic assembly 2 Perform pressure output and control the pressure; the high-pressure oil cylinder 3 is provided with an oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com