Grain direct shear test sample preparation device and sample preparation method

A grain, direct shearing technology, applied in the preparation of test samples, etc., can solve the problems of broken, unable to compact, affecting the design parameters of the granary, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

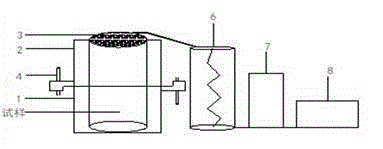

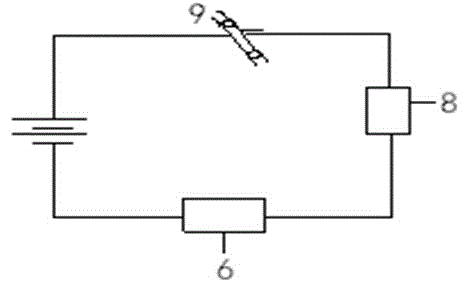

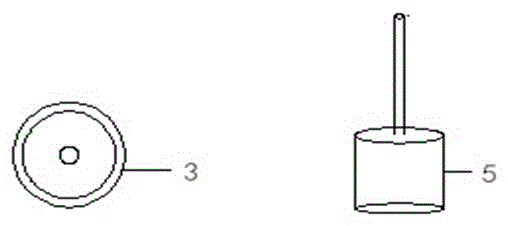

[0021] Such as figure 1 As shown, the grain direct shear test sample preparation device and sample preparation method of the present invention include: a lower shear box 1, an upper shear box 2, a lid 3, a latch 4, a compaction hammer 5, an air pump 6, and an air storage tank 7. Electric motor 8, switch 9.

[0022] Sample preparation methods include:

[0023] 1) Before sample preparation, place the upper and lower shearing boxes in alignment, and insert the pins to fix them; place the shearing boxes stably.

[0024] 2) According to the sample volume and grain density, weigh the mass of the required sample, divide the grain into 5 parts, and use the layered compaction method to load the sample. Each layer of sample is compacted first, when compacted to the point where it cannot be compacted, turn on the air pump switch to allow the gas to flow out fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com