Electromagnetic high vacuum inflation valve

A high-vacuum, inflatable valve technology, applied in the direction of valve details, control valves, valve devices, etc., can solve the problems of difficulty in ensuring the airtightness of the vacuum system and low work efficiency, and achieve the solution of automatic control of the vacuum degree, reliable control, and solution The effect of low efficiency in the vacuum state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

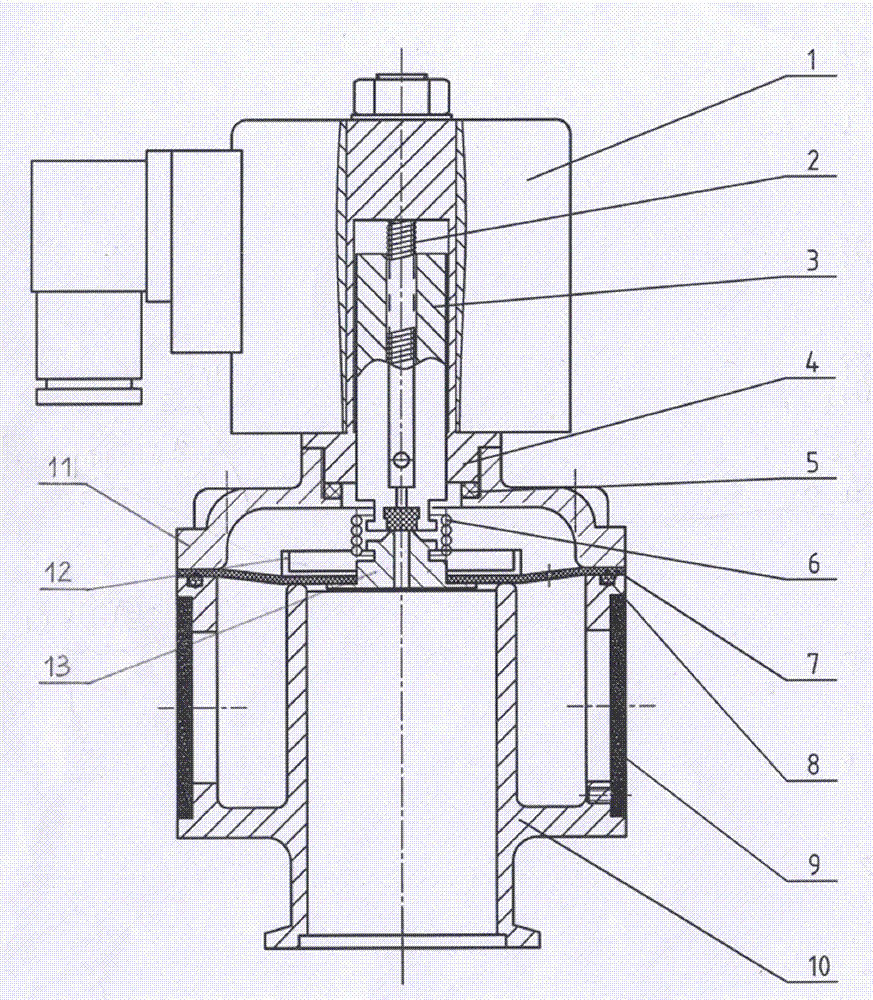

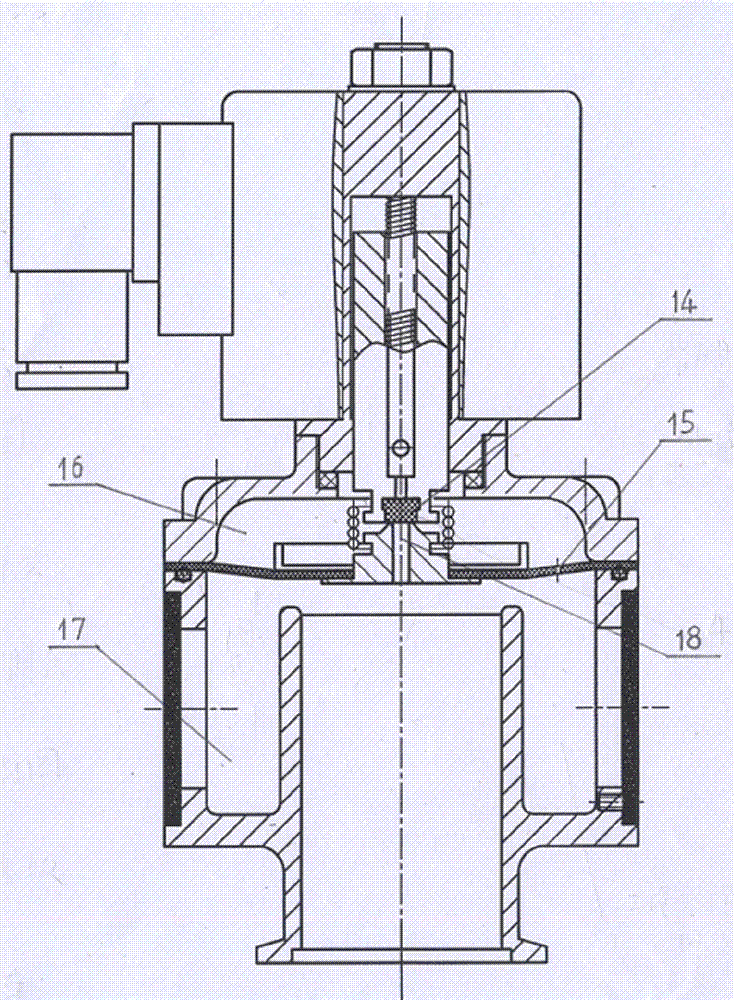

[0021] Such as figure 1 , 2 As shown, an electromagnetic high vacuum inflation valve includes an electromagnetic combination 1, an upper spring 2, an armature 3, a valve core 4, a small sealing ring 5, a lower spring 6, a cloth diaphragm 7, a large sealing ring 8, and a filter plate 9. Main body 10, upper cover 11, membrane cloth pressure plate 12, membrane seat 13 and wear-resistant plug 14. The armature 3 is slidingly matched with the valve core 4, and the upper spring 2 is installed in the inner hole of the armature 3.

[0022] The diaphragm seat 13 has a central hole 18 , and the cloth diaphragm 7 has a small vent hole 15 , the diameter of the small vent hole 15 is smaller than the diameter of the central hole 18 of the diaphragm seat 13 .

[0023] The lower end of the valve core 4 is fastened on the loam cake 11, and the loam cake 11 and the main body 10 are fastened with screws. The periphery of the cloth diaphragm 7 is compressed between the upper cover 11 and the ma...

Embodiment approach 2

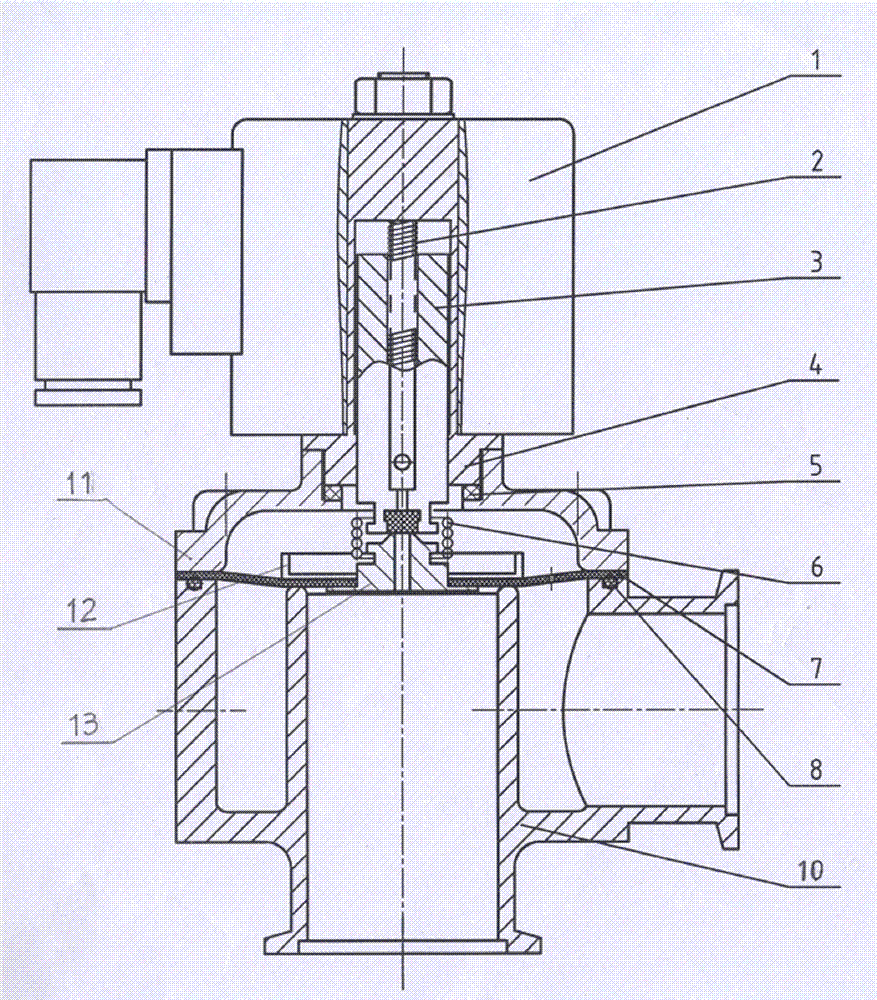

[0031] Such as image 3 , 4 As shown, the electromagnetic high-vacuum inflatable valve with large inflation capacity is connected to the air filter (not shown in the figure) on three sides and closed on one side on the four side windows of the main body 10, or connected to the air filter (not shown in the figure) on two sides and closed on both sides. , or one side is connected to the air filter (not shown in the figure) and three sides are closed.

[0032] The action process of the electromagnetic high vacuum inflation valve is:

[0033] Such as figure 1 , 3 As shown, when the electromagnetic combination 1 is de-energized, the armature 3 is pressed down against the diaphragm seat 13 due to the elastic force of the upper spring 2 . Simultaneously, the tension force of the lower spring 6 presses the diaphragm seat 13 downwards, forcing the cloth diaphragm 7 to be close to the vacuum nozzle in the main body 10 . At this time, the air entering the working gas chamber 17 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com