A preparation method of optical frequency band metamaterial based on gold branched unit

A metamaterial, branched technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the limitations of the wide research and application of metamaterials in the visible light band, the difficulty of preparation, and the complex preparation process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

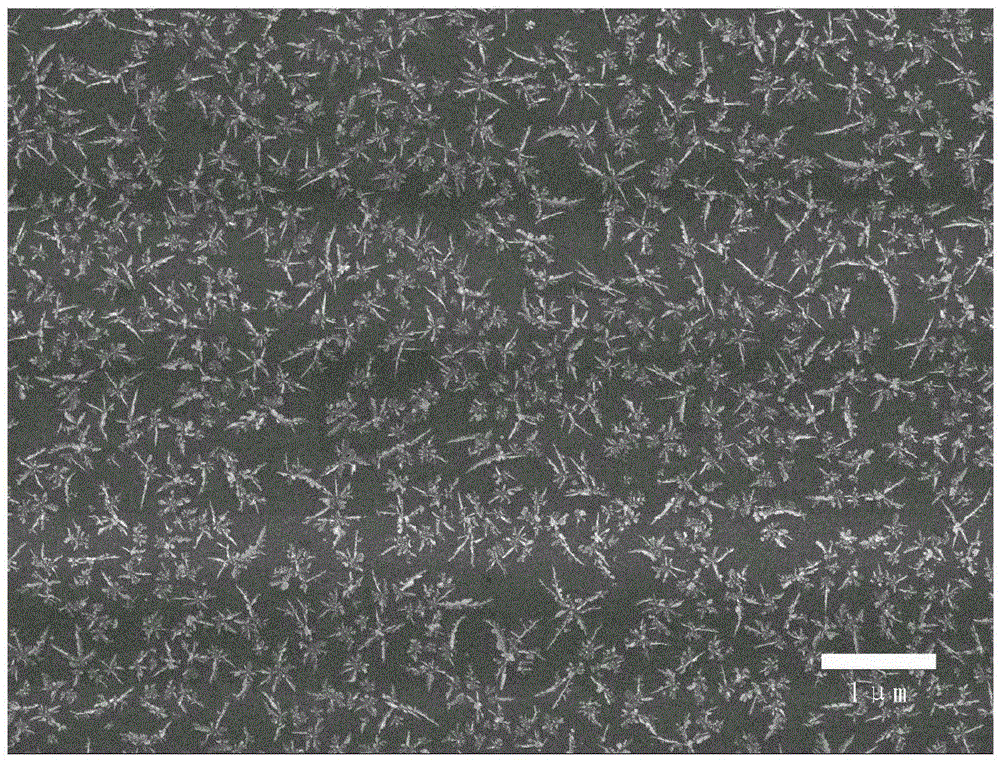

[0026] 1. Preparation of gold branched unit structure: first prepare nano-silver particle sol with an average particle size of 20nm, take 5mL deionized water, mix with 0.01-0.05mL nano-silver particle sol with an average particle size of 20nm, and add 0.05M dodecyltrimethylammonium bromide solution 1.0-2.0mL, 0.01MHAuCl 4 Mix 0.1 mL of the solution with 0.5 mL of a freshly prepared 0.1 M ascorbic acid solution, add to the above solution, and keep it at 25° C. for 10 hours to obtain gold branched units with a diameter of 300-500 nm. After the reaction, 1 mL of 1% (w / v) PVP deionized aqueous solution was added for protection to prevent agglomeration and maintain the morphology of gold branched units.

[0027] 2. Soak the glass sheet in Piranha washing solution (V concentrated sulfuric acid: V hydrogen peroxide = 7:3) for half an hour, and then in dilute ammonia water: H 2 o 2 :H 2 O(V 1:1:1 ) mixed solution, acetone, ethanol and ultrapure water for ultrasonic treatment for 2...

Embodiment 1

[0033] (1) Preparation of gold branched unit:

[0034] Prepare 20mL of 0.25mmol / L silver nitrate solution and 20mL of 0.25mmol / L sodium citrate solution, mix and stir at 2000 rpm for 5 minutes, adjust the speed to 3000 rpm, add 0.1mol in 10 seconds / LNaBH 4 Solution 2mL, continue to stir for 1 hour, obtain the silver particle sol of average particle diameter 20nm.

[0035] Take 0.01mL of the above-mentioned nano-silver particle sol, add it to 5mL deionized water, place it on an electromagnetic stirrer, stir at a speed of 700 rpm, and add 0.05M dodecyltrimethylammonium bromide solution 1.0 after stirring for 1 hour. mL, after standing for half an hour, add 0.01MHAuCl under stirring at 2500 rpm 4Solution 0.1mL and newly prepared 0.1M ascorbic acid solution 0.5mL, after 10 hours at 25°C, add 1% (w / v) PVP deionized water solution 1mL, shake gently by hand, after standing for 5 hours, a gray sol was obtained , pour it into a centrifuge tube and centrifuge at 3000 rpm for 10 min,...

Embodiment 2

[0044] (1) Preparation of gold branched unit:

[0045] Prepare 20mL of 0.25mmol / L silver nitrate solution and 20mL of 0.25mmol / L sodium citrate solution, mix and stir at 2000 rpm for 5 minutes, adjust the speed to 3000 rpm, add 0.1mol in 10 seconds / LNaBH 4 Solution 2mL, continue to stir for 1 hour, obtain the silver particle sol of average particle diameter 20nm.

[0046] Take 0.05mL of the above nano-silver particle sol, add it to 5mL deionized water, place it on an electromagnetic stirrer, stir at a speed of 700 rpm, and add 0.05M dodecyltrimethylammonium bromide solution 2.0 after stirring for 1 hour. mL, after standing still for half an hour, add 0.01M HAuCl4 solution 0.1mL and newly prepared 0.1M ascorbic acid solution 0.5mL under stirring at 2500 rpm, and add 1% (w / v) Shake 2mL of PVP deionized water solution by hand. After standing for 5 hours, a gray sol is obtained. Pour it into a centrifuge tube and centrifuge at a speed of 3000 rpm for 10min. Discard the supernat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com