Method for preparing nano cilium structure on surface of polymer material

A polymer material and composite structure technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high cost and long time required, and achieve the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

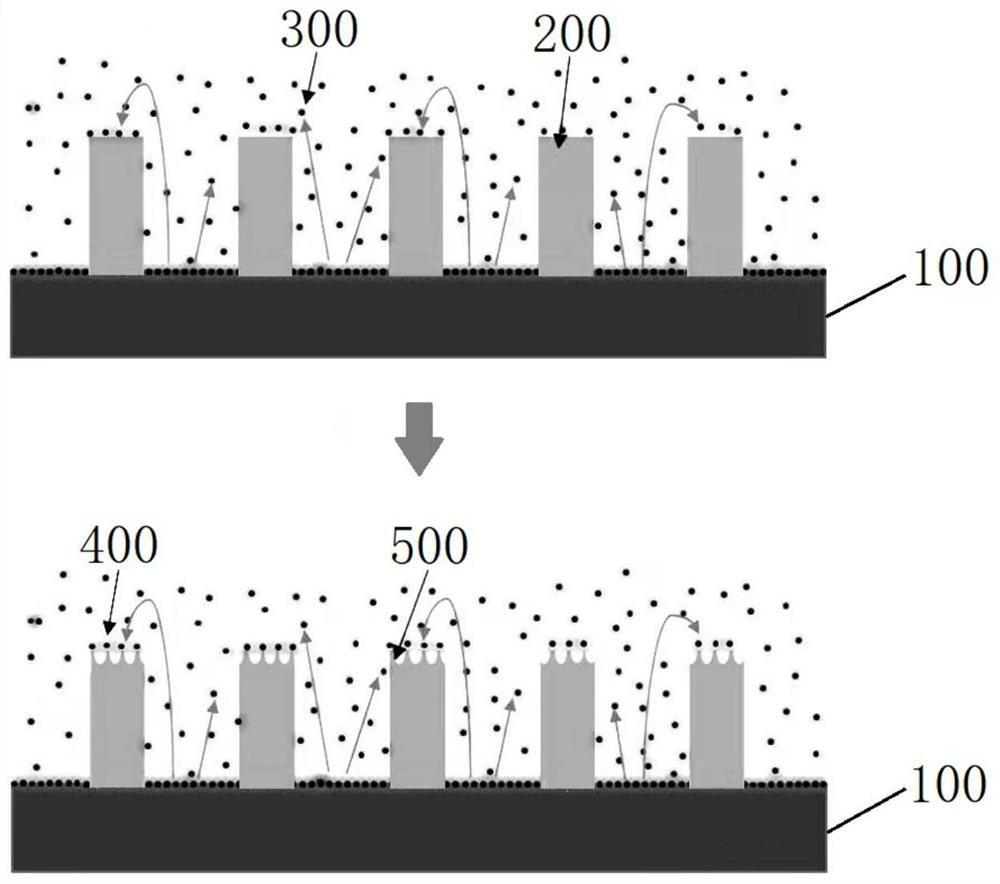

[0037] Because the existing methods for preparing nanofibril structures usually need to adjust the length and distribution density of nanocilia by changing the structural characteristics of the mold or template, this results in high cost and long time. To this end, the present invention provides a new method for preparing a nano-cilia structure on the surface of a polymer material, which specifically includes the following steps.

[0038] First, a polymer film is placed on a metal substrate to obtain a composite structure;

[0039] The metal substrate can be titanium, gold, platinum or copper. The combination ability of metal and polymer film determines its feasibility as a metal micromask. Among the commonly used sputtering target metals, titanium and polymers have stronger adhesion than other metals. Therefore, titanium is easier to form a micro-mask on the surface of polymers than other metals.

[0040] In the present invention, the polymer film is not particularly limite...

Embodiment 1

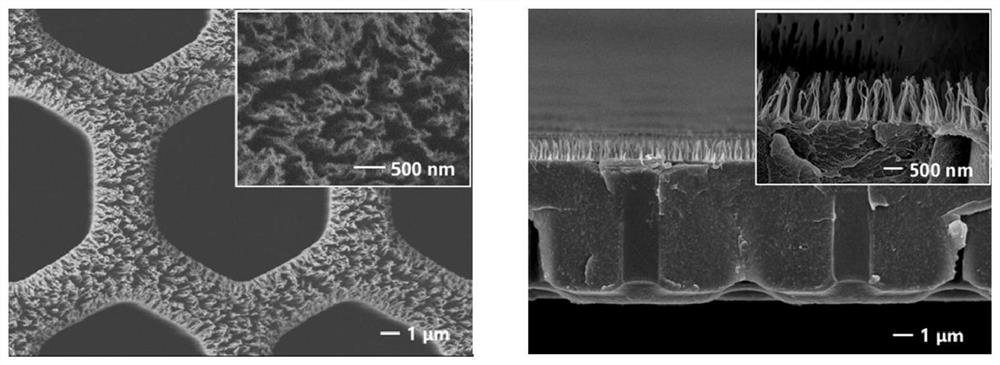

[0060] Firstly, a pre-prepared parylene C film (pore size 8 μm) with a microporous structure was placed on a titanium sheet substrate to obtain a composite structure.

[0061] Then, reactive ion etching was performed on the composite structure as a whole to form a nano-cilia structure, wherein the etching gas was oxygen, the oxygen flow rate was 60 sccm, the etching radio frequency power was 150 W, and the etching time was 300 s. The length of the resulting nanocilia is about 1.2 μm.

[0062] Finally, the titanium sheet substrate was removed to obtain a polymer material with a nano-cilia structure on the surface, and the scanning electron microscope images from different viewing angles are as follows figure 2 shown.

Embodiment 2

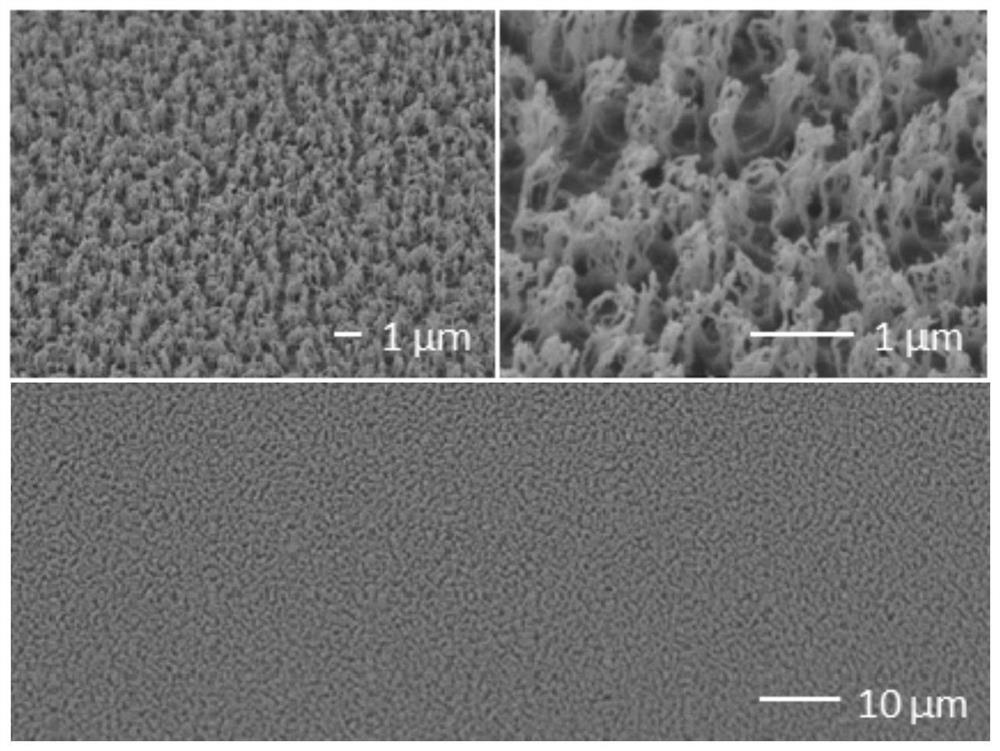

[0064] Carry out according to the method of embodiment 1, the difference is that the parylene C microporous film with microporous structure is replaced with the pre-prepared parylene C film without microporous structure. The length of the resulting nanocilia is about 1.2 μm. The scanning electron microscope image of the polymer material (without microporous structure) with nano-cilia structure on the prepared surface is as follows: image 3 shown. The scanning electron microscope image of the parylene C film without nano-cilia structure and microporous structure (that is, the pre-prepared parylene C film without microporous structure) is as follows: Figure 4 shown.

[0065] The contact angle of the polymer material with nano-cilia structure on the surface is tested with water, and the result is about 0°. This indicates that the polymer material becomes a superhydrophilic surface after being modified with nanocilia. The photo of the contact angle measurement of the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com