A kind of preparation method of max phase base coating

A coating and substrate technology, applied in the field of preparation of MAX phase-based coatings, can solve the problems of low content of MAX phase in the coating and affect the performance of the coating, so as to improve the performance of the coating, improve the corrosion resistance and corrosion resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of MAX phase-based coating, comprising the following steps:

[0034] (1) Mix metal M, Al and C powders by ball milling, dry for use; the metal M is Cr, Nb or Ti;

[0035] (2) Sinter the dried powder to obtain M 2 AlC-MAX phase material;

[0036] (3) will M 2 AlC-MAX phase material is pulverized, made into powder by ball milling, and screened;

[0037] (4) Filter the obtained M 2 The mixed powder obtained by mixing AlC-MAX phase powder with Al powder or the M obtained by screening 2 AlC-MAX phase powder, poured into a metal tube or alloy tube with a melting point not higher than 1100 ° C, made into a metal or alloy coated M 2 AlC-MAX phase powder wire;

[0038] (5) The prepared wire is sprayed onto the surface of the substrate by flame spraying; the M in the wire 2 AlC-MAX phase, Al powder and metal or alloy are sprayed onto the substrate surface.

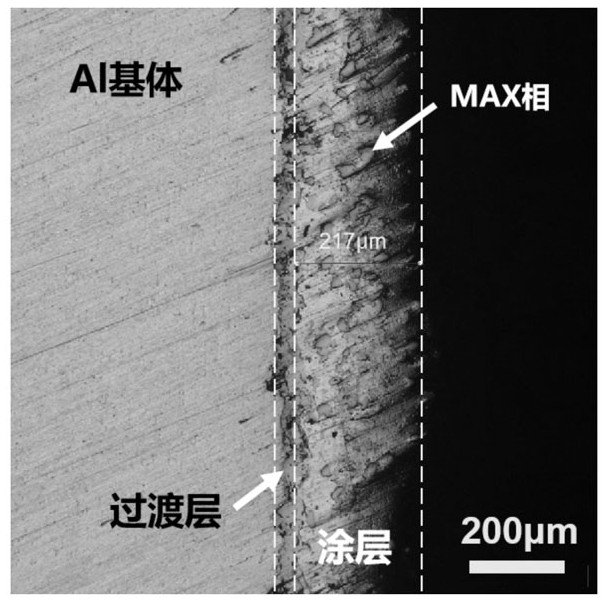

[0039] In this solution, during the spraying process, the molten metal or alloy entrained MAX ...

Embodiment 1

[0052] (1) According to the powder molar ratio Cr: Al: C = 2: 1.1: 1, the elemental powder is mixed and ball-milled, put into the mold, and the furnace temperature is raised to 1400°C at a heating rate of 10°C / min under a vacuum atmosphere. And keep it warm for 3 hours, and keep applying 50MPa pressure during the keep warm process.

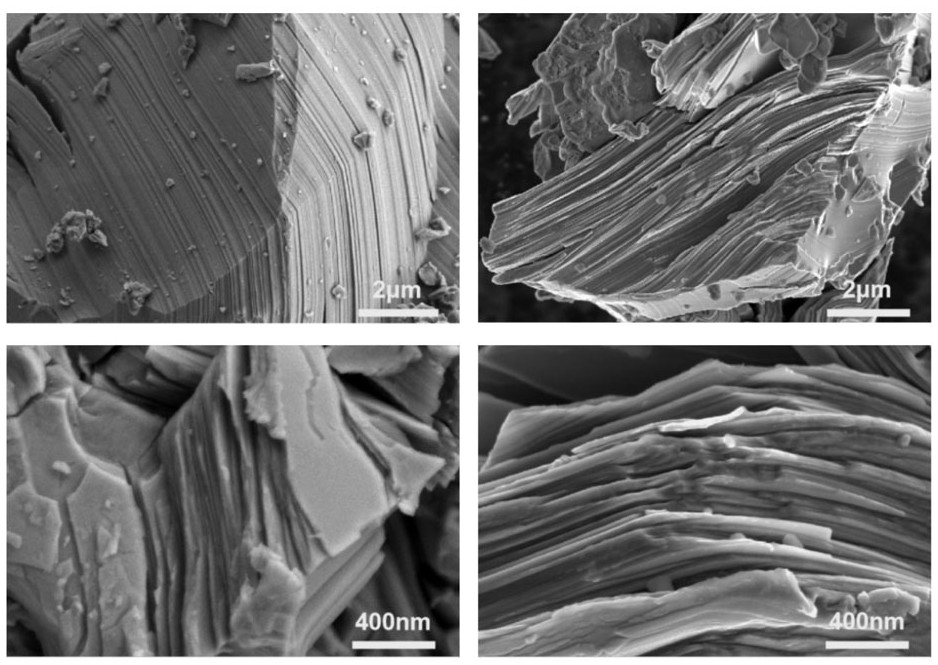

[0053] (2) Take the Cr prepared in step (1) 2 AlC-MAX phase, crushed and made into powder by ball milling and sieved to obtain Cr with a particle size of 200 mesh 2 AlC-MAX phase powder particles. figure 1 for the obtained Cr 2 SEM images of AlC-MAX phase powder particles.

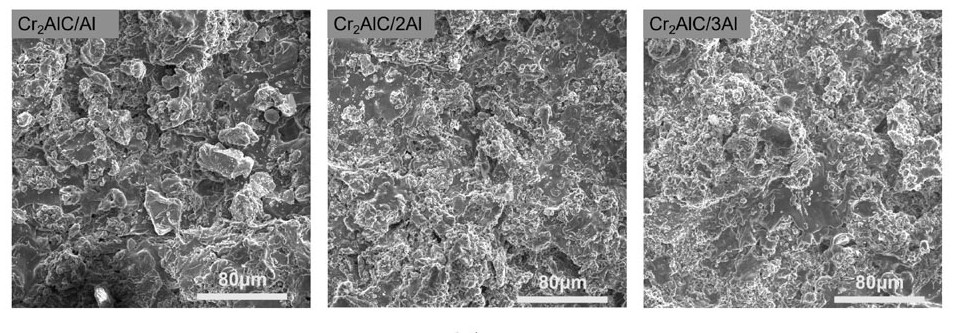

[0054] (3) Take the Cr with a particle size of 200 mesh in step (2) 2 AlC-MAX phase powder is poured into a 6063 aluminum alloy tube with a wall thickness of 0.5mm and an outer diameter of 3mm, and the two ends are sealed with aluminum alloy wire to obtain an aluminum alloy coated Cr tube. 2 AlC-MAX phase powder wire, the wire is named as Cr 2 AlC / Al.

[0055] (4) First...

Embodiment 2

[0058] The difference from Example 1 is that in step (3), Cr 2 AlC-MAX phase powder is mixed with Al powder, and then the mixed powder is poured into the wall aluminum alloy tube, Cr 2 The mixed volume ratio of AlC-MAX phase powder and Al powder is 2:1; the wire obtained in this example is named as Cr 2 AlC / 2Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com