Flue-cured tobacco nicotine content reducing method

A technology of nicotine content, applied in the field of material accumulation in flue-cured tobacco leaves, can solve the problems of excessive inhalation of nicotine, harm, etc., achieve the effect of reducing nicotine content, the method is simple, and is conducive to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

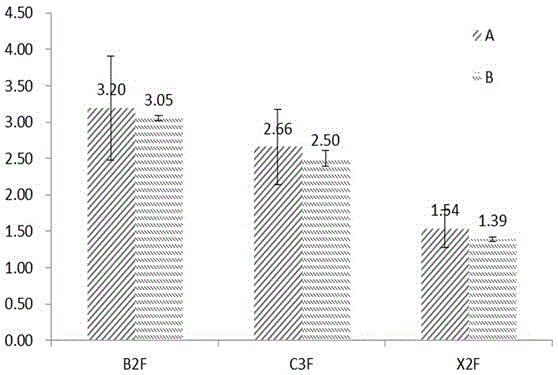

Image

Examples

Embodiment Construction

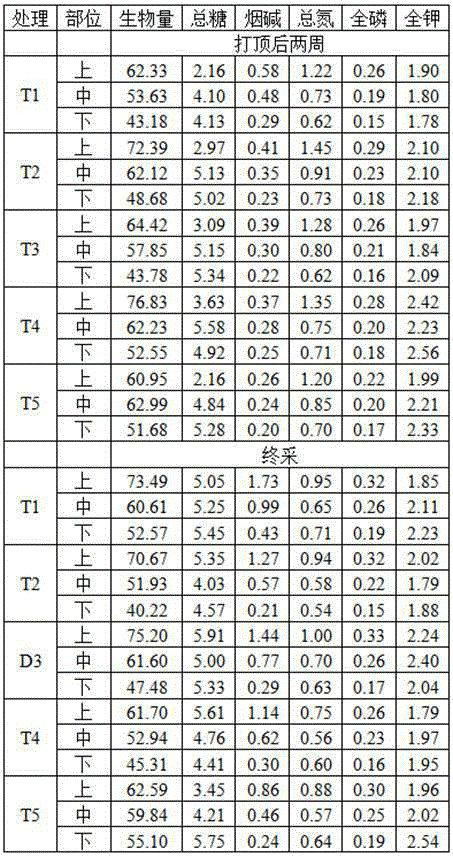

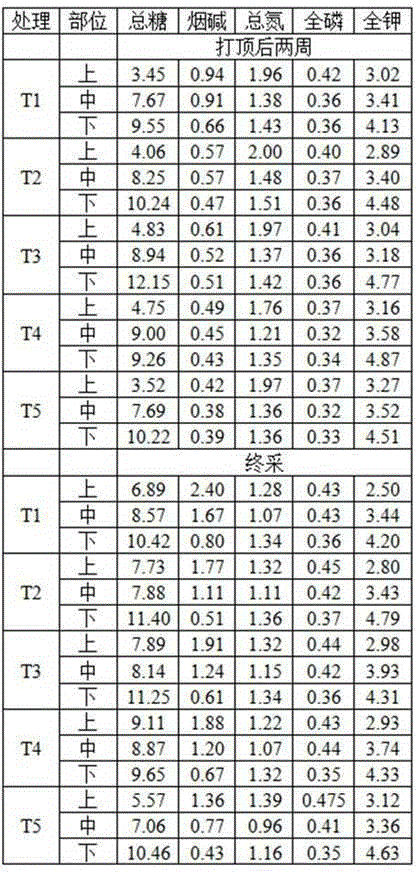

[0011] Materials and Methods

[0012] 1.1 Test time and place

[0013] The experiment was carried out in 2007 at the experimental base of the Tobacco Agricultural Science Research Institute of Fujian Tobacco Monopoly Bureau. The variety tested was Cuibi No.1.

[0014] Test design

[0015] 1.2.1 Experiments with different NAA concentrations

[0016] There are 5 treatments in the experiment:

[0017] T1: Control, topping normally, and lateral buds inhibited by sprout inhibitors.

[0018] T2: Normal topping. Immediately after topping, NAA (concentration 30mM, dissolved in Tween 20 and lanolin, dosage 1.5-2g per plant) was used to treat the stem section, and the sprout suppressant inhibited lateral buds.

[0019] T3: Normal topping. Immediately after topping, NAA (concentration 20mM, dissolved in Tween 20 and lanolin, dosage 1.5-2g per plant) was used to treat the stem section, and the bud suppressant suppressed lateral buds.

[0020] T4: Normal topping. Immediately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com