Adjustable test tube holder

A test tube clamp, adjustable technology, applied in the direction of test tube holder/clamp, etc., can solve the problem of small diameter range and achieve the effect of large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

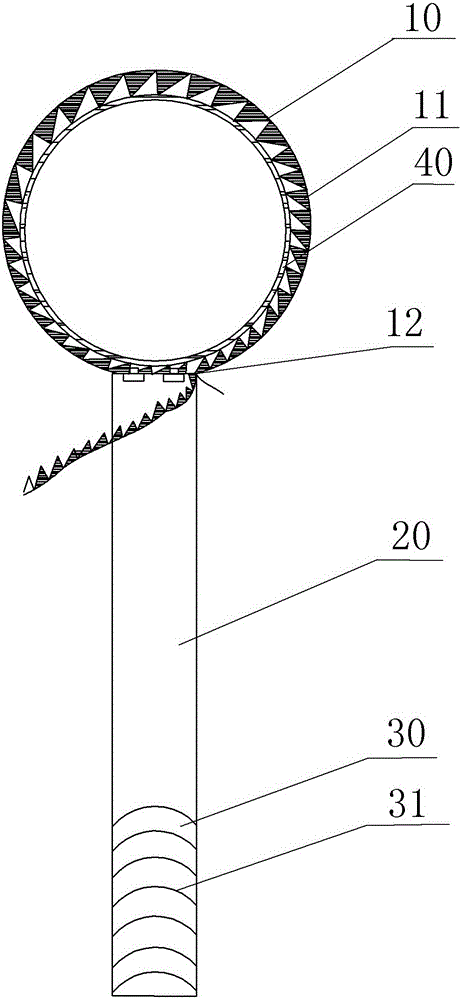

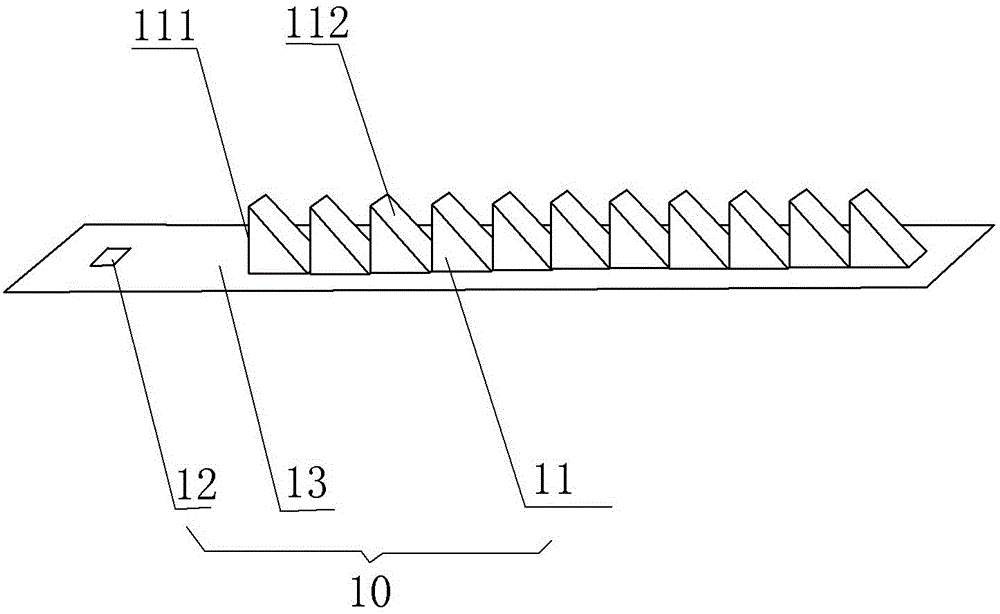

[0021] Embodiment one is basically as attached figure 1 And attached figure 2 Shown:

[0022] Adjustable test tube clamp, including handle 20, polyphenylene ether plastic heat-resistant ring 10 (hereinafter referred to as: heat-resistant ring 10), rubber anti-slip sleeve 30: heat-resistant ring 10 is integrally formed, including heat-resistant ring body 13, positioning hole 12 and Teeth 11, positioning holes 12 and teeth 11 are arranged on the heat-resistant ring body 13; wherein the positioning hole 12 is rectangular, its long side is parallel to the axial direction of the heat-resistant ring 10, and the positioning hole 12 is located at one end of the heat-resistant ring body 13 At least 1cm; tooth 11 includes a blocking surface 111 and a forward surface 112, wherein the blocking surface 111 is perpendicular to the heat-resistant ring body 13, and the advancing surface 112 has an included angle with the heat-resistant ring body 13; when unfolded, the advancing surface 112 ...

Embodiment 2

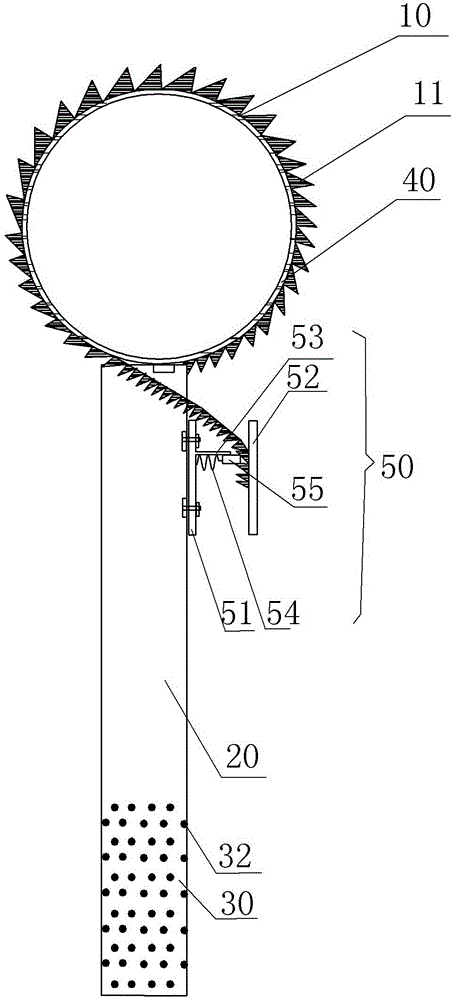

[0024] Embodiment two is basically as attached image 3 As shown: the difference between this implementation and the first embodiment is that the polyimide plastic heat-resistant ring 10 (hereinafter referred to as: heat-resistant ring 10 ) is used, and the rubber anti-slip sleeve 30 used has granular protrusions 32 on the outside. Also comprise buckle 50 in addition; Buckle 50 comprises fixed plate 51, baffle plate 53, limit plate 52, connecting rod, block 55, compression spring 54; Fixed plate 51 is fixed on the handle 20 by bolt connection; Welded on the fixed plate 51 and the limit plate 52 respectively; the baffle plate 53 is welded vertically on the fixed plate 51, the distance between the baffle plate 53 and the limit plate 52 is the height of the tooth 11, the baffle plate 53 is next to the compression spring 54, Set on the top of the compression spring 54; the compression spring 54 and the stopper 55 are arranged between the fixed plate 51 and the limit plate 52; one ...

Embodiment 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the polyphenylene sulfide plastic heat-resistant ring is used, and the fixed connection method between the polyphenylene sulfide plastic heat-resistant ring and the handle is riveting. This embodiment can achieve the same clamping effect as the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap