Drilling device for small head end of automobile exhaust manifold

A drilling device, automobile exhaust technology, applied in the direction of the driving device, boring/drilling, drilling/drilling equipment, etc., can solve the problems of unreliable guarantee of the position of the three holes, low processing efficiency, etc., to achieve Quick and easy disassembly, simple structure, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

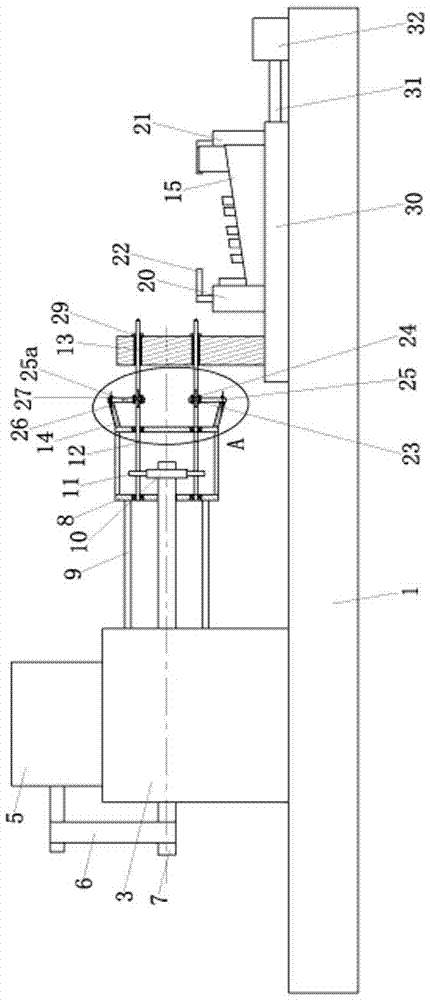

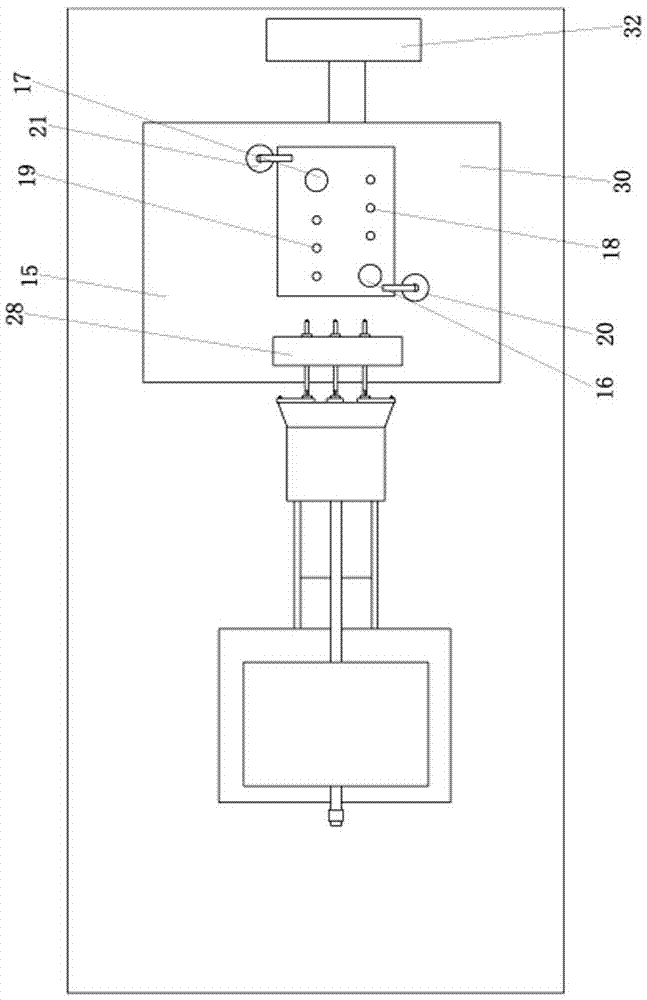

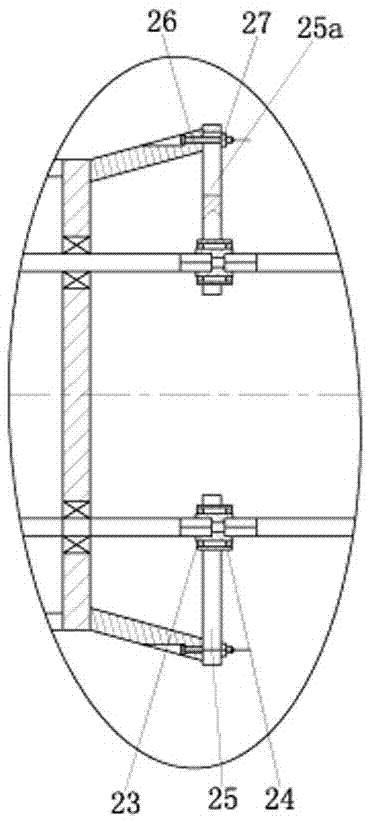

[0019] Such as figure 1 , 2 , Shown in 3, a kind of automobile exhaust manifold small head end drilling device, mainly consists of horizontal bottom plate 1, transmission box 3, motor 5, transmission belt 6, transmission shaft 7, connection box 8, horizontal connection column 9, active large Gear 10, driven pinion 11, drive shaft 12, drill bit 13 and conical connecting bucket 14 etc. constitute. Wherein, the horizontal bottom plate 1 is a rectangular plate, and the horizontal bottom plate 1 is fixed on the base by T-shaped bolts. A transmission case 3 is fixedly provided on the left part of the horizontal bottom plate 1 top surface, and a motor 5 is installed on the transmission case 3 top surface. The driving pulley of this motor 5 output shaft left ends links to each other with the driven pulley on the transmission shaft 7 by transmission belt 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com