Double-gun welding device and machining method

A welding device and welding method technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of multiple welding procedures and low welding efficiency of multi-section pipe fittings, achieve reduced processing procedures, high welding quality, and reduced labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

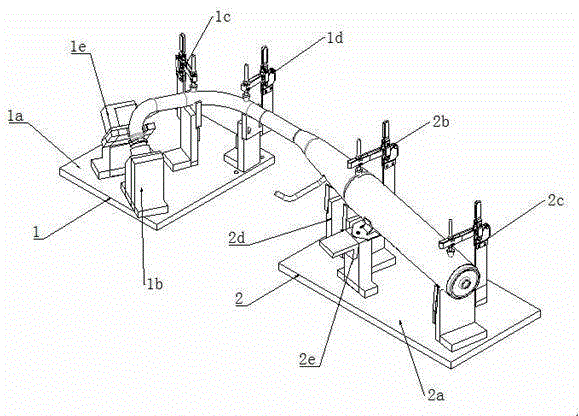

[0020] Example 1, such as figure 1 As shown, a double-gun welding device is provided in this embodiment, including a welding machine and a clamp; the welding machine has two welding torches; the clamp includes a first clamp 1 and a second clamp 2, and the first clamp 1 includes a first clamp body 1a, a first clamp jaw 1b, a second clamp jaw 1c, and a third clamp jaw 1d; the first clamp jaw 1b, the second clamp jaw 1c and the third clamp jaw 1d are all fixed on the On the first clamping body 1a; a pneumatic clamping device 1e is also fixed on the first clamping body 1a. The end of the pipe is clamped by the pneumatic clamping device 1e, so as to avoid shaking and loosening of the end of the pipe during the rotation of the clamp and affect the welding quality. The second clamp 2 includes a second clamp body 2a, a fourth clamp jaw 2b, and a fifth clamp jaw 2c, and the fourth clamp jaw 2b and the fifth clamp jaw 2c are fixed on the second clamp body 2a; It includes a clamp rotat...

Embodiment 2

[0022] Embodiment 2, a double-gun welding method is provided in this embodiment, comprising the following steps:

[0023] (1) Sleeve the two ends of the second pipe on the first pipe and the third pipe respectively;

[0024] (2) Clamp and fix the first pipe with the first jaw, the second jaw and the third jaw, clamp and fix the third pipe with the fourth jaw and the fifth jaw, and the fixed first pipe and the second The three pipes support and position the second pipe;

[0025] (3) Adjust the two welding torches of the welding machine to both ends of the second pipe respectively, aiming at the weld between the second pipe and the first pipe and the seam between the second pipe and the third pipe respectively;

[0026](4) Start the welding machine for welding, and simultaneously start the fixture rotation device to rotate the first fixture and the second fixture synchronously to complete the circumferential welding of the pipe fittings.

[0027] The distance between the weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com