Gantry type sapphire wafer double-sided grinding/polishing machine and grinding and polishing method

A sapphire wafer, double-sided grinding technology, applied in the field of polishing machines, can solve the problems of difficult grinding and polishing of sapphire wafers, left and right shaking of the cantilever structure, and high hardness of sapphire, achieves both stability and aesthetics, optimizes the polishing process, and improves stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

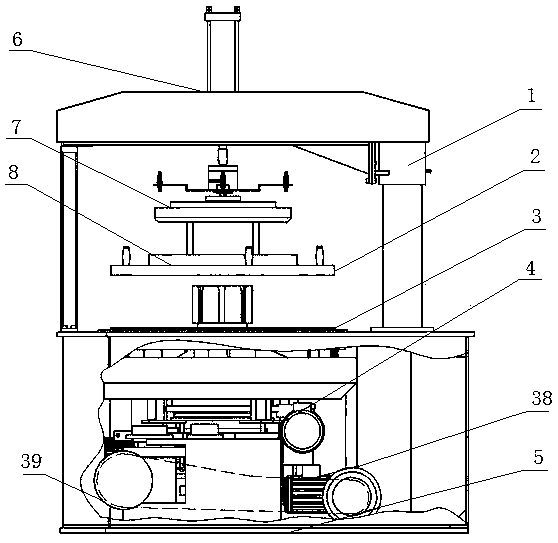

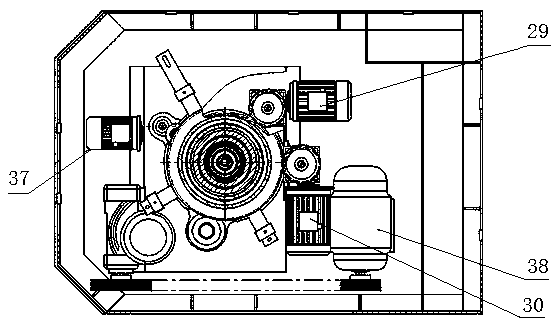

[0033] A double-sided grinding / polishing machine for gantry-type sapphire wafers, comprising: a box body and a bottom plate system 5, a power transmission system 4 is installed inside the box body and the bottom plate system, and the upper plane of the box body and the bottom plate system A lifting support system 1 is installed, and a hydraulic system 6 is installed on the top of the lifting support system. The front end of the hydraulic system is connected to the grinding bearing 7 through a connecting shaft, and an upper grinding system 2 is installed below the grinding bearing. The power transmission system is connected with motor A38, motor B30, motor C29, motor D37 by transmission belt respectively.

Embodiment 2

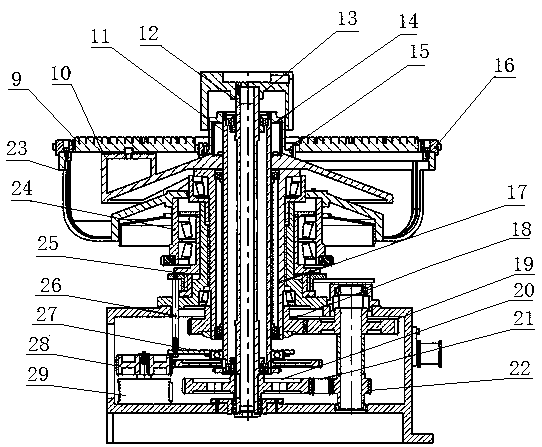

[0035] According to the gantry type sapphire wafer double-sided grinding / polishing machine described in embodiment 1, there is an upper grinding disc 8 above the upper grinding system, the lower grinding system 3 is below the upper grinding system, and the motor A38 passes through The transmission belt is connected with the deceleration helical gear 39, the deceleration helical gear meshes with the lower helical gear 22 and the upper helical gear 19 respectively, the described lower helical gear meshes with the direction changing helical gear 21, and the described direction changing helical gear meshes with the main helical gear The transmission lower helical gear 20 meshes, the main transmission lower helical gear is connected with the main shaft 12, the grinding disc drive sleeve 13 is installed outside the main shaft, the upper helical gear meshes with the outer transmission helical gear 18, and the The outer transmission helical gear is connected with the outer transmission...

Embodiment 3

[0037] According to the gantry type sapphire wafer double-sided grinding / polishing machine described in embodiment 1, the motor B is connected with the external transmission spur gear 31 through a connecting shaft, and the external transmission spur gear meshes with the spur gear A32, and the The spur gear is connected with the outer seat 24 of the bearing seat, and the outer seat of the bearing seat is connected with the support seat 23 of the large ring gear, and the large ring gear 16 is installed above the support seat of the large ring gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com