Air bag polishing device with online detection function based on industrial robot

An industrial robot and airbag polishing technology, which is applied in the direction of grinding/polishing safety devices, manufacturing tools, grinding drive devices, etc., can solve the problem that the surface quality cannot be monitored and fed back in real time, the airbag polishing equipment does not have the online detection function, and the workpiece Single types of problems, to achieve the effect of optimizing the airbag polishing process, eliminating external vibration, and high-efficiency cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

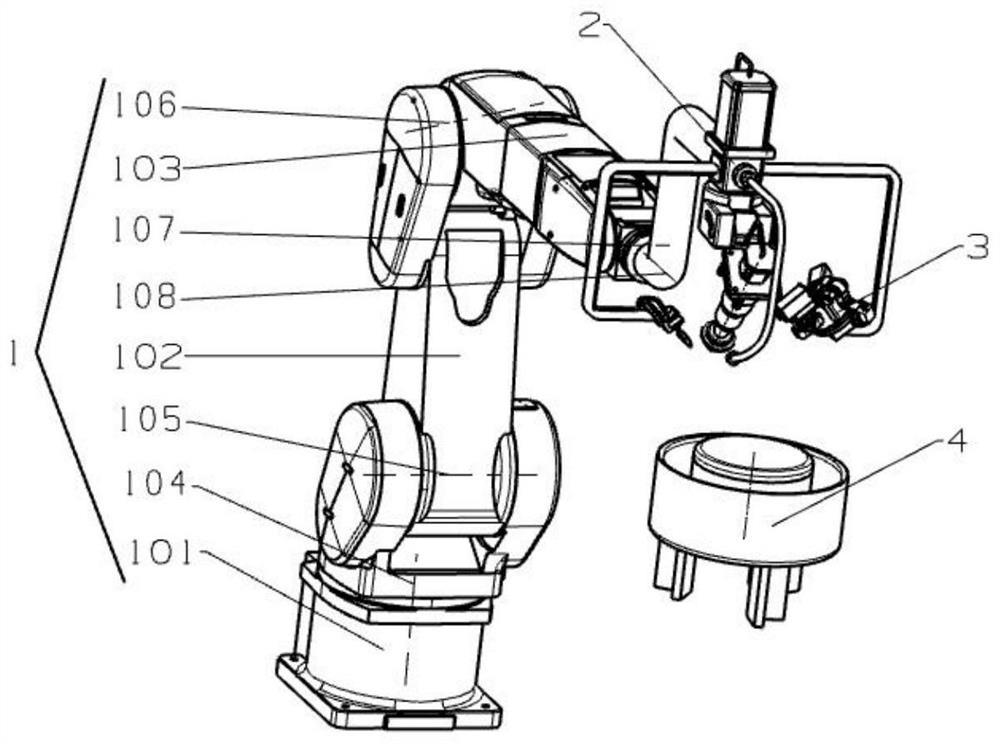

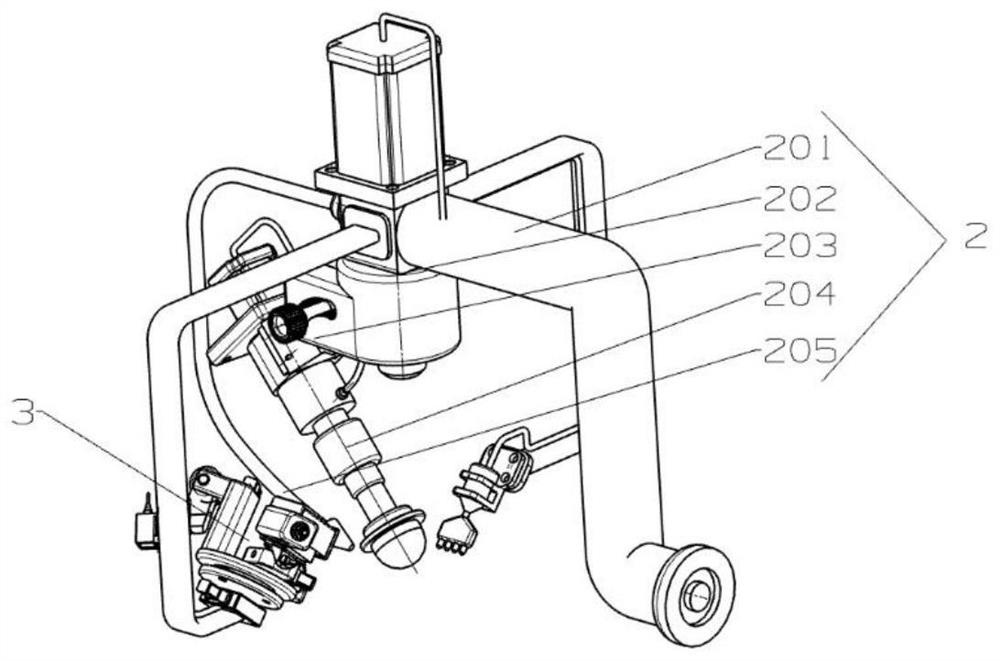

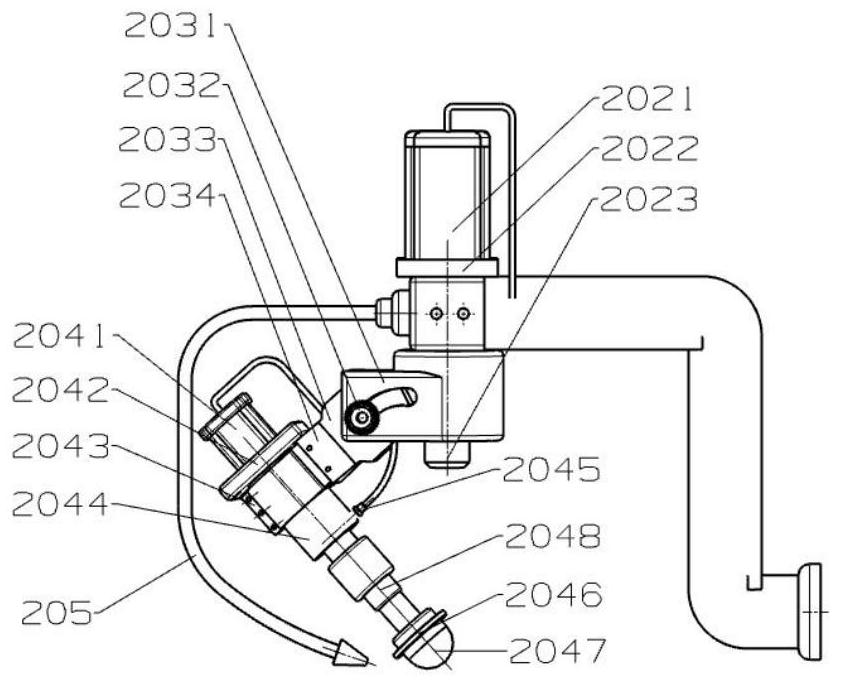

[0031] An airbag polishing device with on-line detection based on industrial robots, such as figure 1 As shown, it includes an industrial robot module 1 , a precession polishing module 2 , an online detection module 3 and a workbench module 4 .

[0032] Industrial Robot Module 1, such as figure 1 As shown, it includes a base 101, a boom 102 and a small arm 103, the base 101 is connected to the first end of the boom 102, the second end of the boom 102 is connected to the first end of the small arm 103, and the second end of the small arm 103 end and the first end of the connection bracket 201 in the precession polishing module 2 is connected.

[0033] Specifically, the industrial robot module 1 has five axes, which are respectively the first rotation axis 104 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com