Automatic loading device and technological method of electrical spiral brick press

A technology of automatic feeding and electric screw, which is applied in the direction of feeding devices, manufacturing tools, ceramic molding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

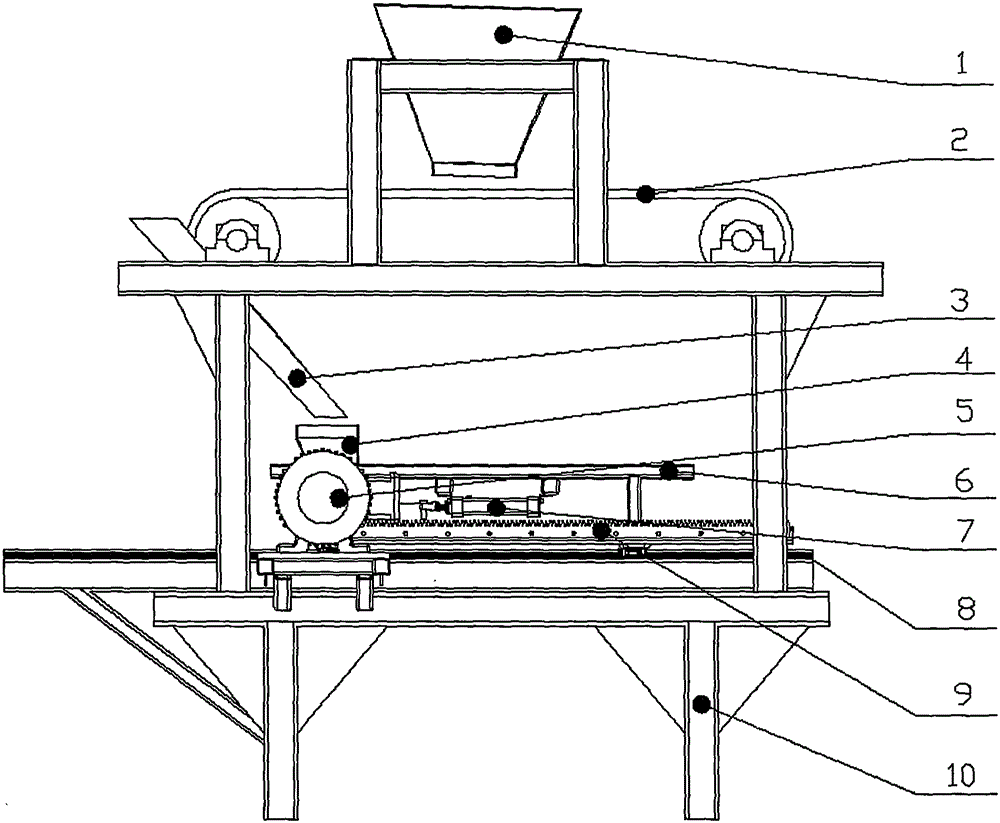

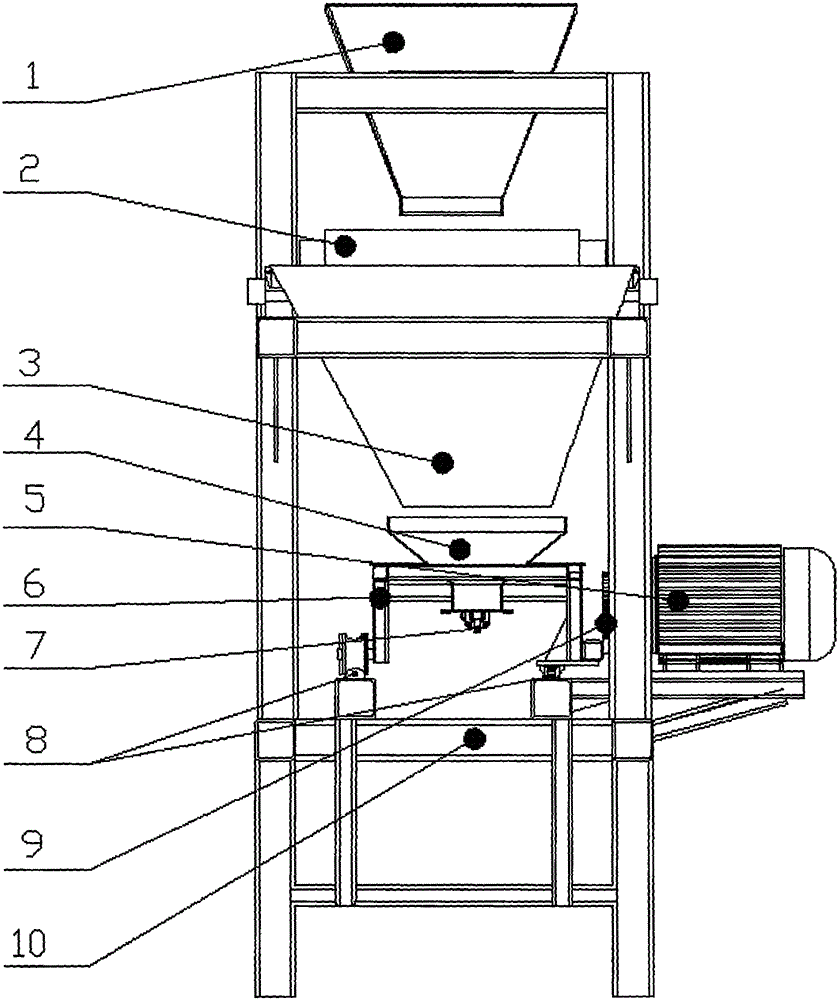

[0059] As shown in the figure, an automatic feeding device for an electric screw press consists of: storage hopper mechanism 1, electric conveyor belt device 2, material guide slideway 3, program-controlled silo device 4, asynchronous motor 5, and remote control conveying trolley 6. The automatic opening cylinder 7, the rolling conveying guide rail 8, the rack and pinion transmission auxiliary device 9, and the automatic feeding frame 10; A storage hopper mechanism 1 is provided, a program-controlled silo device 4 is provided below, and a guide slideway 3 is correspondingly provided between the program-controlled hopper device 4 and the electric conveyor belt device 2 .

[0060] The lower part of the automatic feeding frame 10 is provided with a rolling conveying guide rail 8, and the upper part of the rolling conveying guide rail 8 is provided with a remote control conveying trolley 6, and a rack and pinion transmission auxiliary device 9 is set correspondingly meshing between...

Embodiment 2

[0063] As shown in the figure, a process method for automatic feeding of an electric screw press brick press, the specific process steps are as follows:

[0064] Step 1: Prepare and mix the raw materials in advance and store them in the storage hopper mechanism 1;

[0065] According to the performance of refractory materials, the crushed powdery raw materials are mixed into granular objects with water or resin as the medium, and the density is 1.82g / cm 3 -2.46g / cm 3 The weight of the material that can be accommodated by the storage hopper mechanism 1 is set to 0.5-1.5 tons, or according to the usual production capacity of the single machine of the refractory manufacturer, the production capacity of at least 1 day is supplied; Self-weight automatic downward positioning transmission;

[0066] Step 2: Start the electric conveyor belt device 2, drive the asynchronous motor 5 to move and take away the raw materials in the storage hopper mechanism 1, and enter the program-controll...

Embodiment 3

[0074] As shown in the figure, a process method for automatic feeding of an electric screw press brick press, the specific process steps are as follows:

[0075] Step 1: Prepare and mix the raw materials in advance and store them in the storage hopper mechanism 1;

[0076] According to the performance of refractory materials, the crushed powdery raw materials are mixed into granular objects with water or resin as the medium, and the density is 1.82g / cm 3 The weight of the raw materials that can be accommodated by the storage hopper mechanism 1 is set to 0.5 tons, or according to the usual production capacity of the refractory manufacturer's single machine, the production capacity of at least 1 day is supplied; the single wall of the storage hopper mechanism 1 adopts a 12 ° inclination angle, and the raw material is automatically downward by using its own weight positioning transmission;

[0077] Step 2: Start the electric conveyor belt device 2, drive the asynchronous motor 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com