Three-dimensional printer with polishing function

A three-dimensional printer, functional technology, applied in the direction of additive processing, etc., can solve the problems of printing nozzle and feeding pipe blockage, jagged, affecting the next use, etc., to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

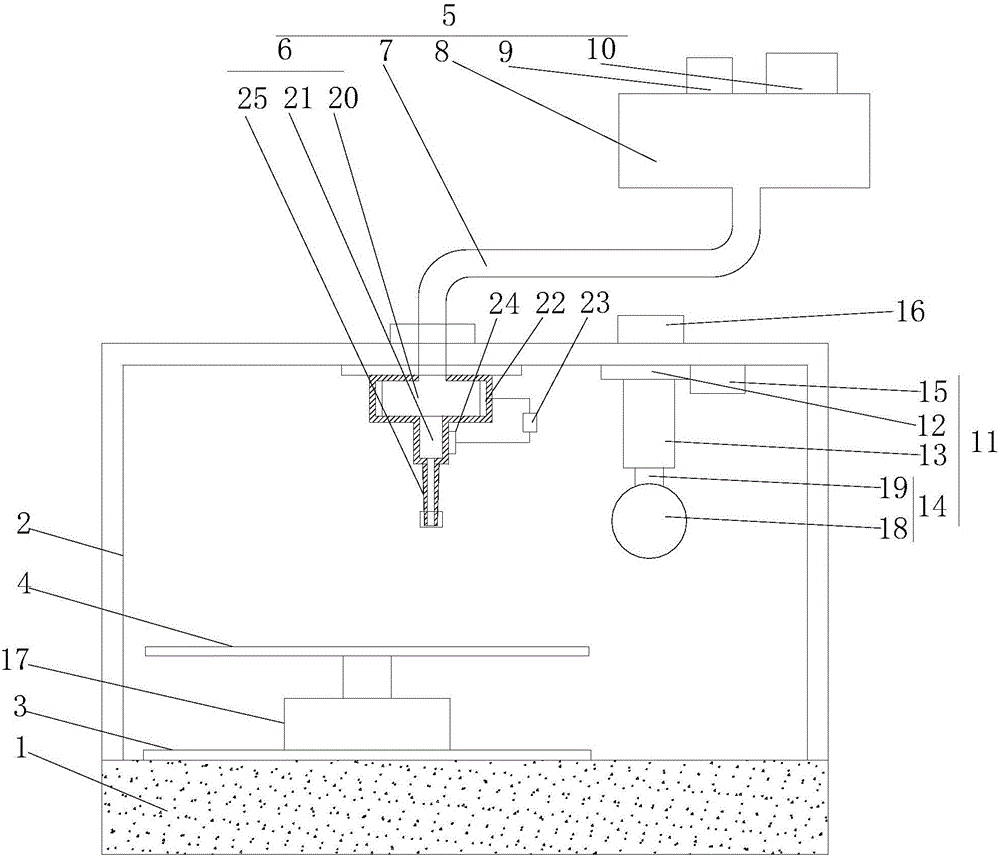

[0019] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a 3D printer with grinding function proposed by the present invention.

[0020] refer to figure 1 , a three-dimensional printer with a grinding function proposed by the present invention, including a base 1, a support frame 2, a rotating table 3, a lifting device, a workbench 4, a printing device 5 and a grinding device 11;

[0021] The support frame 2 is arranged on the base 1, the rotating table 3 is installed on the base 1 in rotation, the rotating table 3 is connected with the rotating drive mechanism, and is driven to rotate by it, the lifting device is arranged on the rotating table 3, and the working table 4 is arranged horizontally on the lifting On the device, the lifting device and the worktable 4 can rotate together with the turntable 3. During specific implementation, the lifting device is set to include a drive cylinder 17, which is fixed on the turntable 3, and the output rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com