Hard alloy mould labeling equipment

A cemented carbide and mold technology, which is applied in the field of cemented carbide mold labeling equipment, can solve the problems of affecting the labeling process, uncontrollable label paper force, and looseness, and achieves easy fixing, wide range of distance adjustment, and easy adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

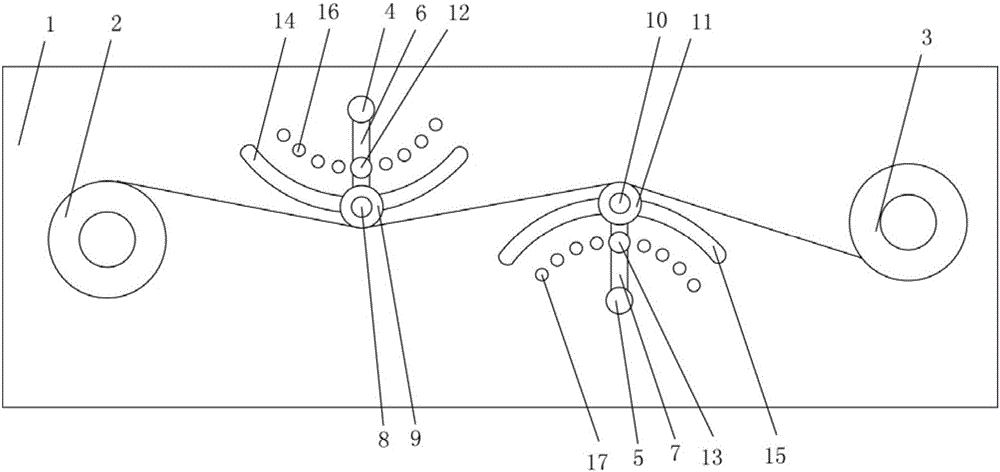

[0018] like figure 1 As shown, a cemented carbide mold labeling equipment includes a fixed plate 1, a winding wheel 2, an unwinding wheel 3, a first rotating shaft 4, a second rotating shaft 5, a first connecting rod 6, a second connecting rod 7, The first roller shaft 8, the first roller 9, the second roller shaft 10, the second roller 11, the first screw 12, the second screw 13, the winding wheel 2 is installed on one end of the fixed plate 1, and the unwinding wheel 3 is installed on the At the other end of the fixing plate 1, the fixing plate 1 is provided with a first slot 14 and a second slot 15. The first slot 14 and the second slot 15 are arc structures with opposite bending directions. The first slot 14 , The second slot 15 is located between the rewinding wheel 2 and the unwinding wheel 3 in turn, the first rotating shaft 4 is installed on the fixed plate 1 and is located on one side of the first slot 14, and the first rotating shaft 4 is located in the first opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com