Spiral winding device

A winding device and spiral technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems affecting the production progress and yield, increase the work intensity of workers, limit the length of winding, etc., to reduce the The frequency of refueling, long winding length, and the effect of increasing winding length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

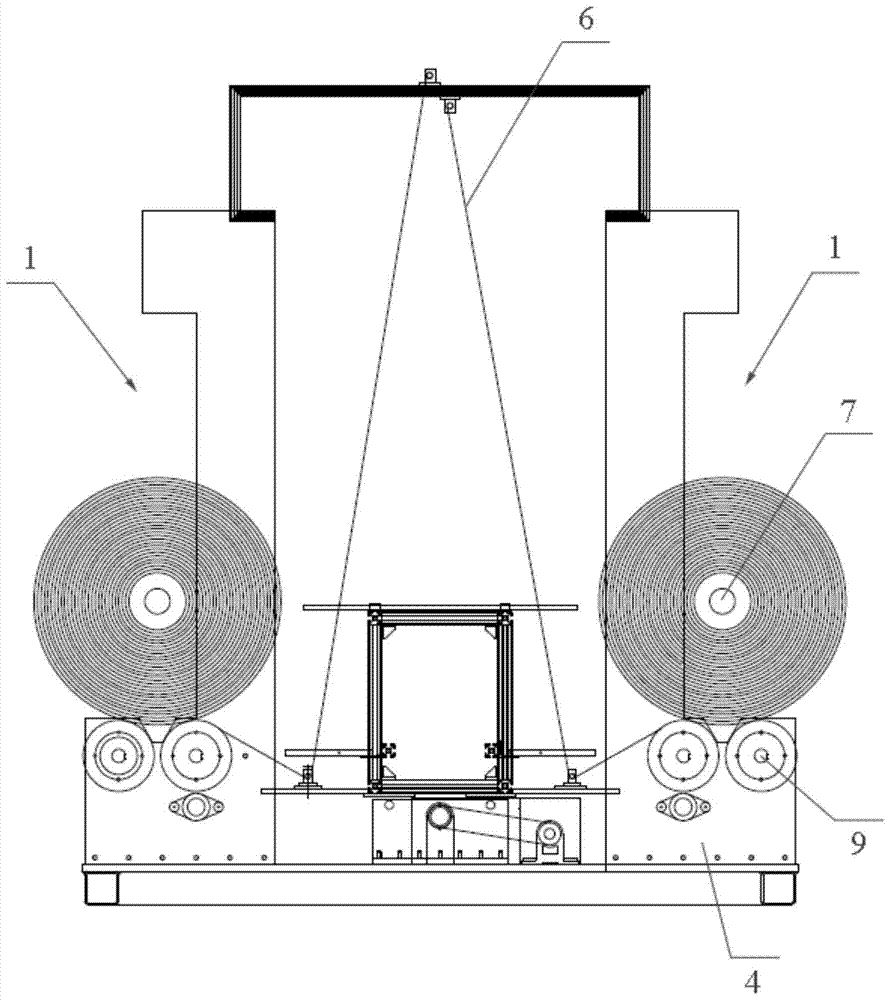

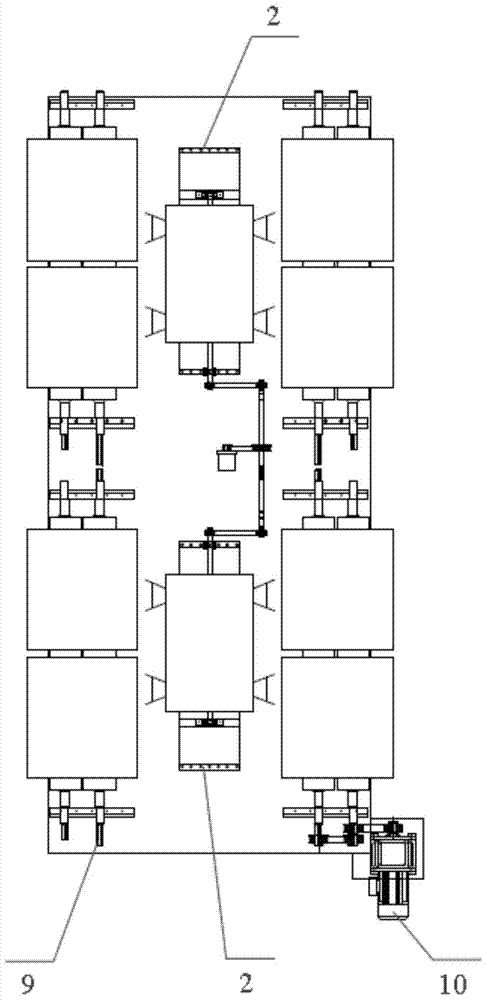

[0025] see Figure 1 to Figure 3 As shown, the present invention provides a spiral winding device composed of a plurality of spiral winding systems 1 . Each spiral winding system 1 is the smallest unit of the spiral winding device, which includes a slide table 2, a paper threading support 3 arranged on the slide table 2, a winding device 4 arranged on one side of the slide table 2, and a The first driving device 5, wherein the paper threading support 3 is connected with a product 6 to be rolled.

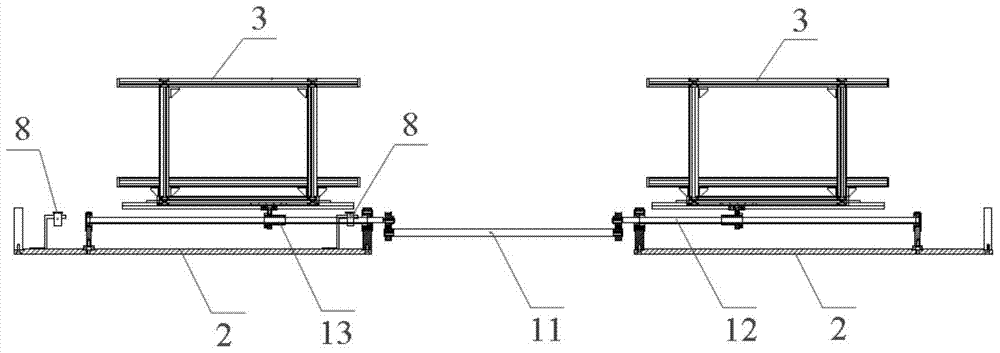

[0026] see Figure 4 As shown, the first driving device 5 is a servo motor, which is connected to the transition shaft 11 through a pulley, and the transition shaft 11 is connected to a ball screw 12 through a pulley. The rotation of the servo motor drives the transition shaft 11 to rotate, and further drives the ball screw 12 to rotate. The ball screw 12 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com