Rotary kiln type spray-drying system

A drying system and rotary kiln technology, applied in spray evaporation, evaporator accessories, etc., can solve the problems of difficult operation, maintenance, cleaning product replacement, large investment in supporting infrastructure, poor thermal insulation effect of high towers, etc. The effect of convenient operation and maintenance and prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment, and the embodiment shown below does not play any limitative effect to the content of the invention described in the claim, and, the whole content of the composition that the following embodiment represents is not limited to be described in the claim necessary for the invented solution.

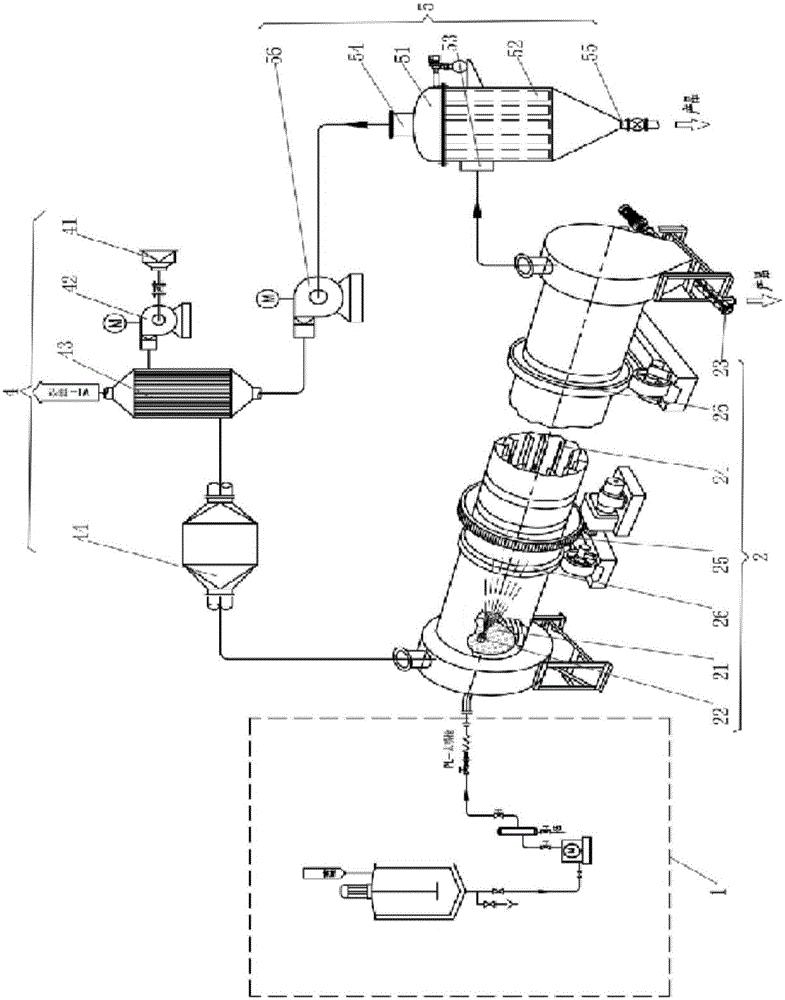

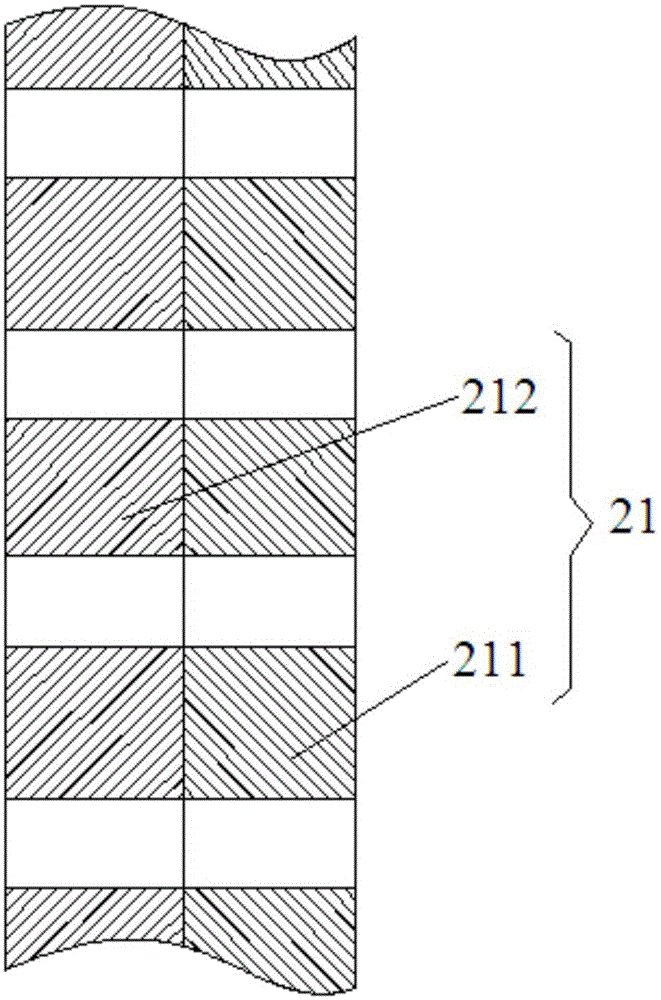

[0023] A rotary kiln spray drying system as shown in the accompanying drawings, the system includes a feed system 1, a hot air system 4, an exhaust gas purification device 5 and a spray drying device 2; the spray drying device 2 includes a horizontal drying chamber and a wheel set , the horizontal drying cavity includes a front part of the cavity, a rear part of the cavity, and a middle part of the cavity that is movably connected with the front part of the cavity and the rear part of the cavity. The wind cover 21 and the atomizing nozzle 22, the inner wall of the front part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com