Integral lifting sling for long vertical steel bars

A vertical steel bar and integral technology, which is applied in the direction of load hanging components, erection/assembly of bridges, bridges, etc., can solve the problems of increased difficulty in installing steel bars, low efficiency of crane operations, and difficulty in ensuring installation accuracy, etc., to improve hoisting Stability and safety, improving the efficiency of steel bar hoisting and installation, and controlling the effect of steel bar installation spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

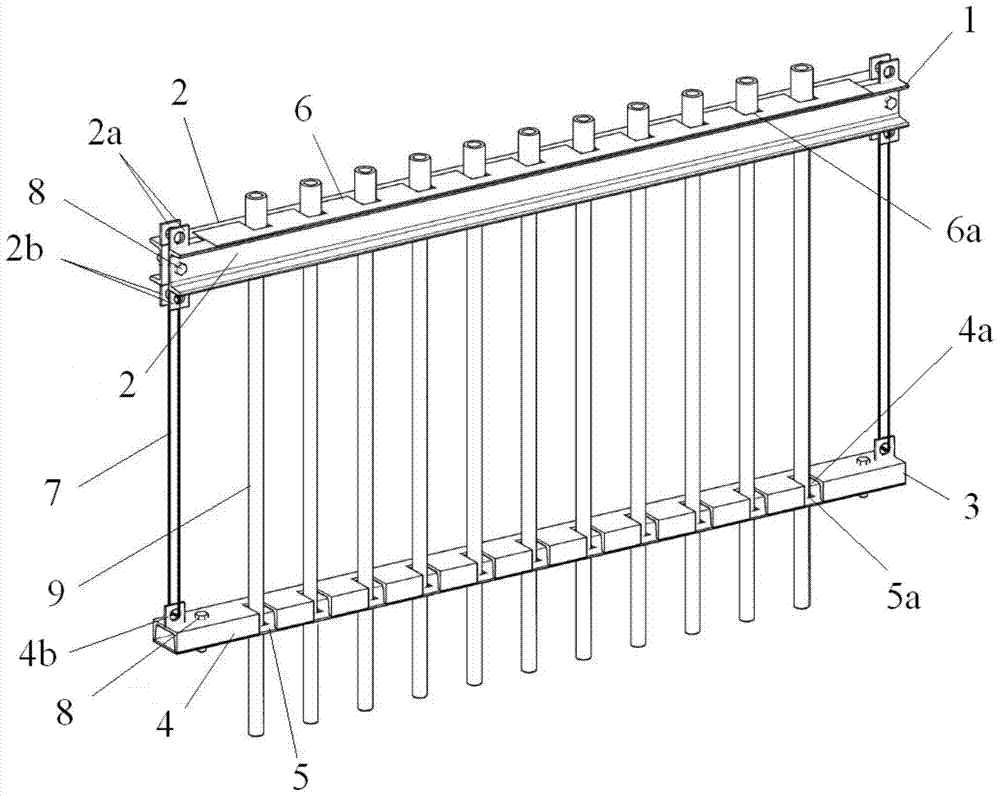

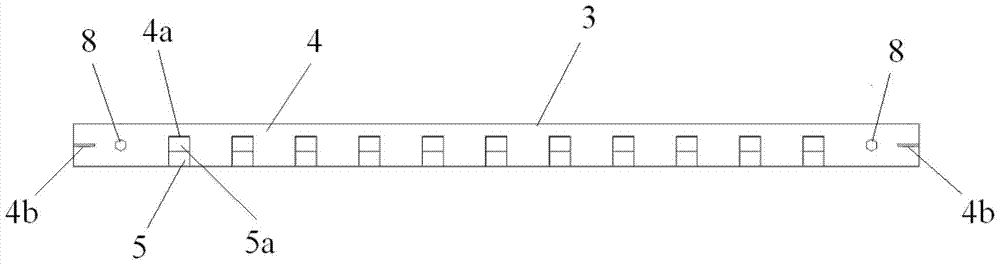

[0030] Example: Combine Figure 1~Figure 3 Shown is a specific embodiment of the long vertical steel bar integral hoisting sling of the present invention, which consists of an upper hoisting beam 1 connected by a steel wire rope 7 and a lower socket-type steel bar swing-proof limiting device 3 for A plurality of steel bars 9 are lifted once.

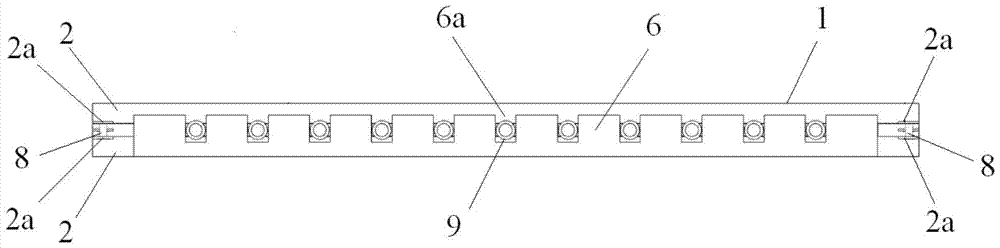

[0031] Concrete combination figure 1 and figure 2 As shown, the composition of the hoisting beam 1 in this embodiment includes clamping plates 2 on both sides to clamp the steel bars 9 by locking the transverse bolts 8; 6. Positioning slots 6a for the corresponding insertion of the hanging steel bars 9 are arranged at intervals on the steel bar positioning clamping plate 6 . In this embodiment, the number of positioning slots 6a is 11, and they are evenly spaced. And in this embodiment, the tops of both ends of the two splints 2 are uniformly provided with lifting lugs 2a, which are used for lifting by lifting equipment.

[0032] c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com