Anti-counterfeiting metamerism ink as well as preparation method and printing method of anti-counterfeiting metamerism ink

A metamerism and ink technology, applied in ink, household utensils, applications, etc., can solve the problems of color difference highlighting, etc., and achieve the effect of long effective time, not easy to be copied, and effective time is not easy to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]This embodiment discloses an anti-counterfeiting metamerism ink, which comprises the following components in terms of mass percentage: 55% metamerism pigment, 18% silicon-modified acrylic resin, 5.5% butyl acrylate, 5% Epoxy resin, 2% near-infrared absorber, 3% isopropanol, 5% absolute ethanol, 4% deionized water, 1.5% sec-butylamine, 0.5% terpineol, 0.2% Defoamer and 0.3% leveling agent.

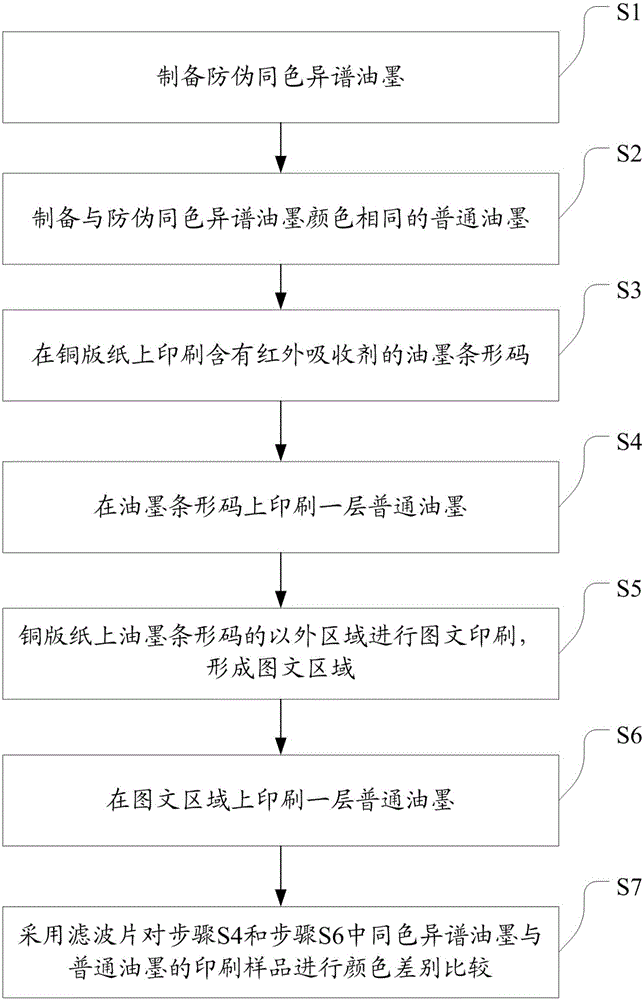

[0052] Such as figure 1 As shown, the present embodiment provides a printing method using anti-counterfeiting metamerism ink, comprising steps:

[0053] S1. Prepare the anti-counterfeit metamerism ink according to the above mass percentage, and ensure that the viscosity of the anti-counterfeit metamerism ink is 18-20 seconds measured by 3# Zahn cup;

[0054] S2. Prepare common ink with the same color as that in step S1, and ensure that the viscosity of the common ink is 15-20 seconds measured by 3# Zahn cup;

[0055] S3, using offset printing process at 157g / m 2 Ink barcodes conta...

Embodiment 2

[0062] This embodiment discloses an anti-counterfeiting metamerism ink, which comprises, by mass percentage: 60% of metamerism pigment, 15% of silicon-modified acrylic resin, 6% of butyl acrylate, and 4% of epoxy resin , 2.2% near-infrared absorber, 3% isopropanol, 3% absolute ethanol, 4% deionized water, 1% sec-butylamine, 1% terpineol, 0.5% defoamer and 0.3% leveling agent.

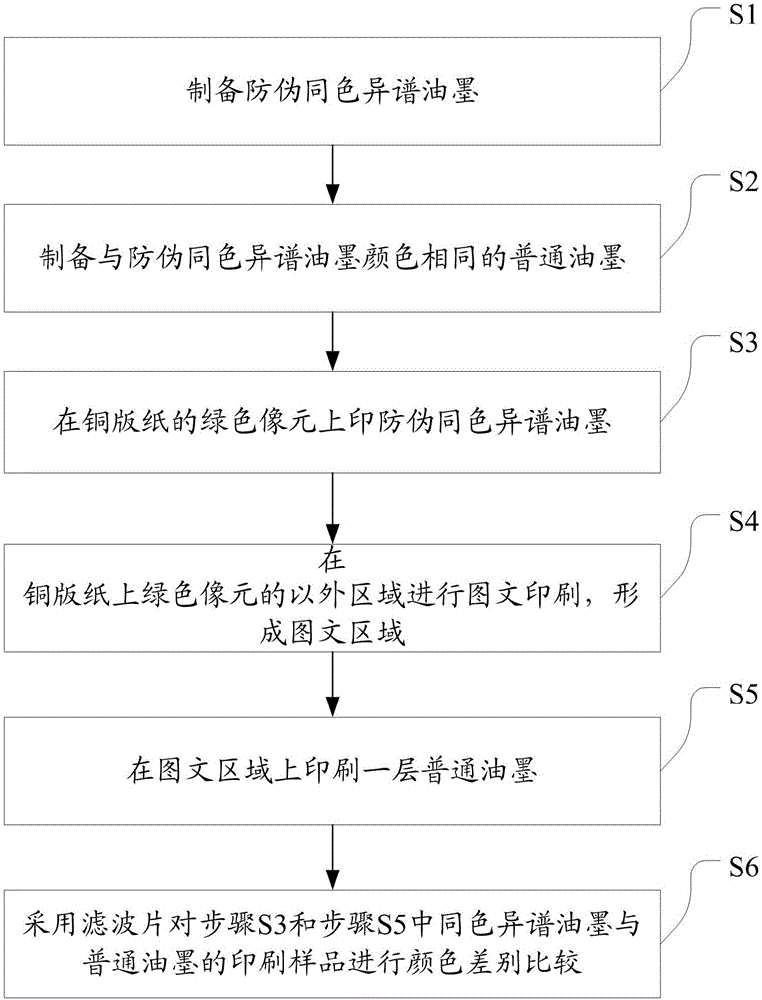

[0063] Such as figure 2 As shown, the present embodiment provides a printing method using anti-counterfeiting metamerism ink, comprising steps:

[0064] S1. Prepare the anti-counterfeit metamerism ink according to the above mass percentage, and ensure that the viscosity of the anti-counterfeit metamerism ink is 18-20 seconds measured by 3# Zahn cup;

[0065] S2. Prepare common ink with the same color as that in step S1, and ensure that the viscosity of the common ink is 15-20 seconds measured by 3# Zahn cup;

[0066] S3, using offset printing process at 157g / m 2 The anti-counterfeiting metamerism i...

Embodiment 3

[0073] This embodiment discloses an anti-counterfeiting metamerism ink, comprising: 50% metamerism pigment, 16% silicon-modified acrylic resin, 8% butyl acrylate, 8% epoxy resin, 2.7% near Infrared absorber, 4% isopropanol, 3% absolute ethanol, 6% deionized water, 0.5% sec-butylamine, 1.5% terpineol, 0.2% defoamer and 0.1% fluid leveling agent.

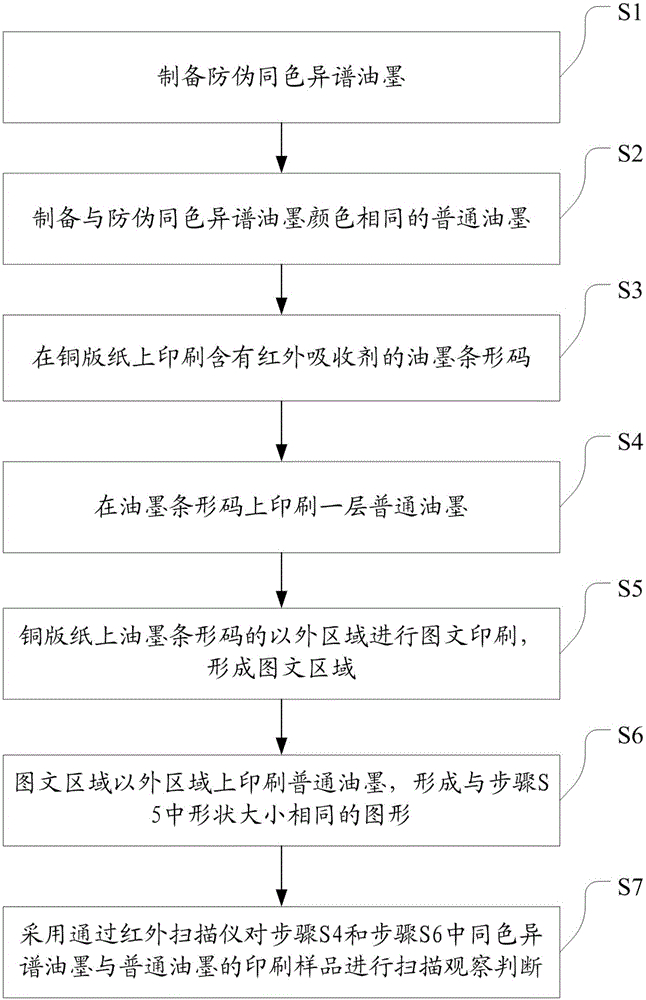

[0074] Such as image 3 As shown, the present embodiment provides a printing method using anti-counterfeiting metamerism ink, comprising steps:

[0075] S1, prepare anti-counterfeit metamerism ink according to the mass percentage described in claim 4, and ensure that the viscosity of the anti-counterfeit metamerism ink is 18-20 seconds measured by 3# Zahn cup;

[0076] S2. Prepare common ink with the same color as that in step S1, and ensure that the viscosity of the common ink is 15-20 seconds measured by 3# Zahn cup;

[0077] S3, using offset printing process at 157g / m 2 Ink barcodes containing infrared absorbers are printed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com