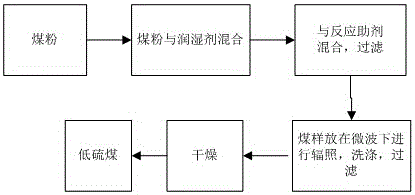

Method for desulphurization through oxidation of high-sulfur coal with combination of microwaves and auxiliary agents

A high-sulfur coal and microwave technology, applied in the field of coal desulfurization, can solve the problems of high desulfurization efficiency, low organic sulfur removal rate, slow bacterial growth, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A desulfurization method for oxidizing high-sulfur coal with microwave combined with additives: the raw coal in this embodiment is Nantong coal.

[0036] Put 20g of Nantong coal crushed, screened (particle size less than 74um) and dried into a 250ml Erlenmeyer flask, add 2ml of alcohol to wet the coal sample, then add 100ml of 2mol / L NaOH solution and 100ml of 2% NaOH Hydrogen peroxide, stirred at room temperature for 30 minutes, and then filtered, the filtered coal sample was subjected to microwave irradiation for 15 minutes, the microwave power was 1000W, the coal sample was taken out, filtered and washed until the filtrate pH<9, the NaOH and hydrogen peroxide remaining on the surface were removed, and the The coal sample filter cake obtained by filtration was dried in a drying oven at 110°C for 3-4 hours to obtain low-sulfur coal.

[0037] The total sulfur content in the low-sulfur coal obtained in Coal Example 1 was detected by the Ischka method.

[00...

Embodiment 8

[0044] Embodiment 8: A desulfurization method for oxidizing high-sulfur coal with microwave combined with additives: the raw coal in this embodiment is Laigang coal.

[0045]Put 20g of crushed, sieved (particle size less than 300um) dried Laigang coal into a 250ml Erlenmeyer flask, add 2ml of alcohol to wet the coal sample, then add 100ml of 4mol / L NaOH solution and 100ml of 4% hydrogen peroxide, at room temperature Stir at low temperature for 10 minutes, then filter, irradiate the filtered coal sample with microwave for 5 minutes, the microwave power is 300W, take out the coal sample, filter and wash until the filtrate pH<9, remove the residual NaOH and hydrogen peroxide on the surface, put the filter cake Dry it in a drying oven at 110°C for 3 hours to obtain low-sulfur coal.

[0046] The method desulfurization effect of embodiment 8 is as table 3:

[0047] table 3

[0048] coal type Sulfur content before desulfurization Sulfur content after desulfurization...

Embodiment 9

[0050] Put 20g of crushed, sieved (particle size less than 150um) dried Nantong coal into a 250ml Erlenmeyer flask, add 1ml of alcohol to wet the coal sample, then add 100ml of 4mol / L NaOH solution and 100ml of 10% hydrogen peroxide, at room temperature Stir at low temperature for 20 minutes, without microwave irradiation, wash directly, filter and separate, take out the coal sample, filter and wash the filtrate pH<9, remove the residual NaOH and hydrogen peroxide on the surface, put the filter cake in a drying oven at 90°C for drying 4h to get low-sulfur coal.

[0051] The method desulfurization effect of embodiment 9 is as table 4:

[0052] Table 4

[0053] coal type Sulfur content before desulfurization Sulfur content after desulfurization Desulfurization rate Nantong Coal 2.84% 1.72% 39.57%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com