Rolling oil composition used for cold rolling of common carbon steel plate with size less than 650mm and preparation method of rolling oil composition

A rolling oil and composition technology, applied in lubricating composition, petroleum industry, etc., can solve problems such as over-lubrication, high saponification value, vibration of rolling mill, etc., and achieve anti-rust performance, reasonable saponification value, and cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

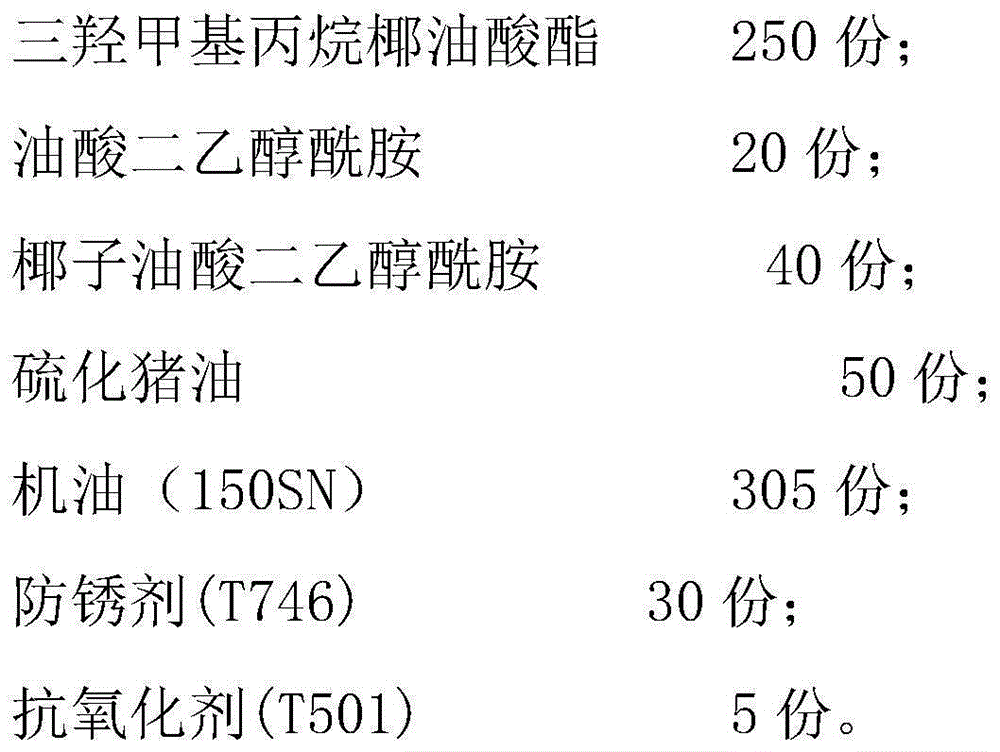

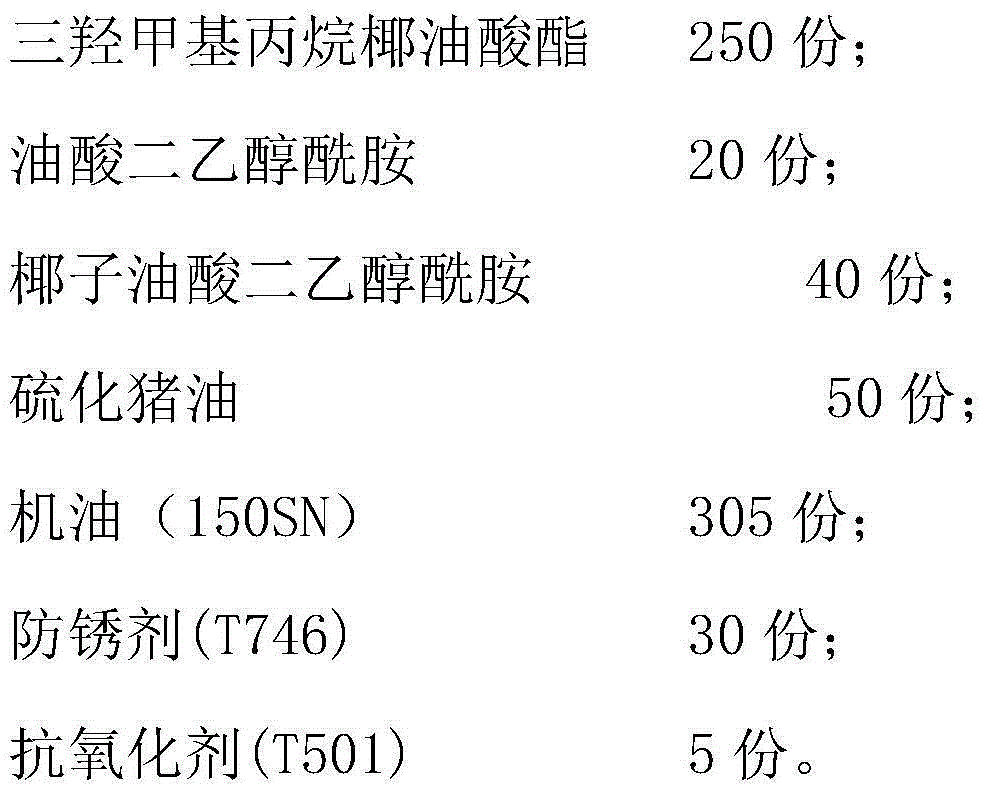

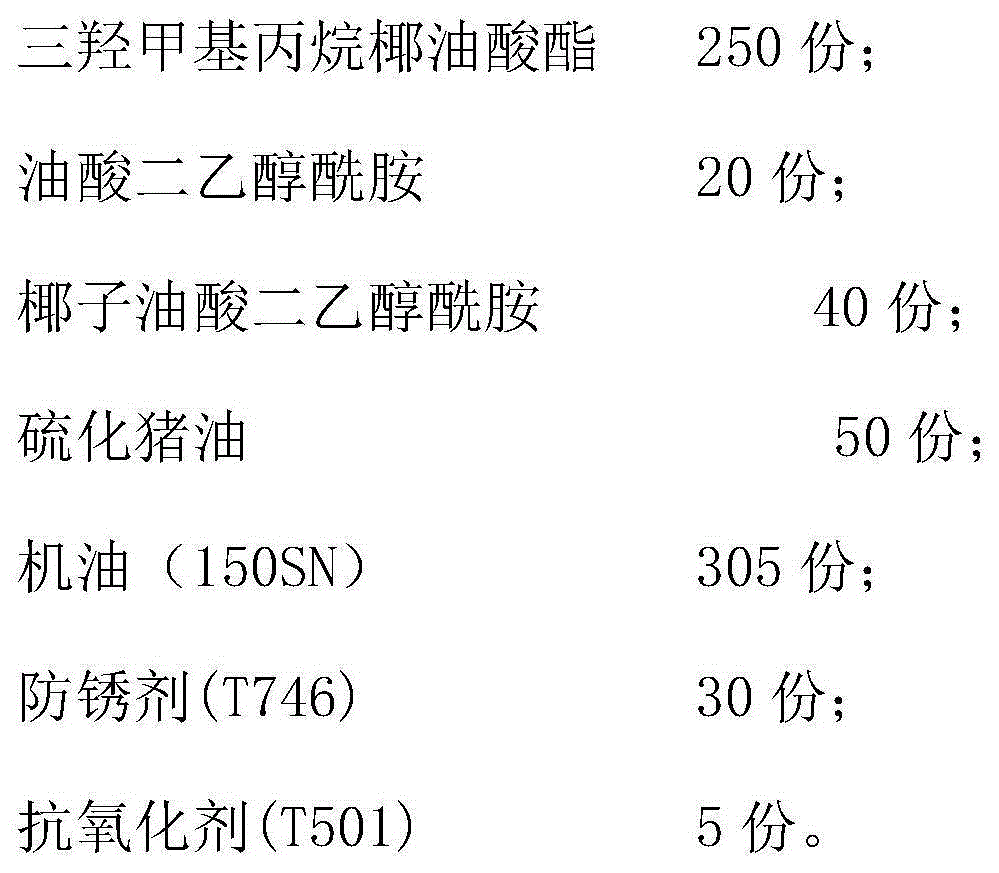

[0017] A rolling oil composition for cold-rolling common carbon steel plates below 650 mm, comprising the following components in parts by weight:

[0018]

[0019] In this embodiment, the engine oil is 150SN base oil, the rust inhibitor is T746 rust inhibitor, and the antioxidant is T501 antioxidant.

[0020] The rolling oil composition preparation method of the present embodiment is as follows:

[0021] Step 1, add engine oil, heat up to 60-70°C, add antioxidant, stir until dissolved;

[0022] Step 2, cool down to 60°C, add trimethylolpropane cocoate, and vulcanized lard and stir evenly;

[0023] Step 3: add antirust agent at 50°C, stir for 30 minutes, then add oleic acid diethanolamide and coconut oleic acid diethanolamide and stir for 30 minutes to obtain the composition of the present invention.

[0024] The index data of rolling oil composition of the present invention is as shown in the following table:

[0025] Table 1 The combination of physical and chemical ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com