Automatic vertical condensation dyeing machine for silk by utilizing microwaves

A dyeing machine, vertical technology, applied in the field of dyeing machines, can solve the problems of high tension and high temperature of silk, and achieve the effect of good consistency of finished products and high dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

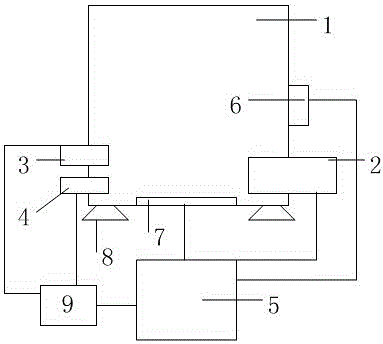

[0013] Such as figure 1 As shown, the present invention includes a dyeing vat 1, a magnetron 6, a temperature detector 3, a concentration meter 4, a condenser 2, a controller 5, and a PLC control system 9; the magnetron 6 is installed in the dyeing vat The outer wall of the body 1, the detection points of the temperature detector 3 and the concentration meter 4 are located at the lower part of the inner wall of the dyeing vat, and the cooling end of the condenser 2 is located in the dyeing vat 1; There is a turntable 7 on the bottom surface, and the speed of the turntable 7 is <30r / min; the controller 5 controls the magnetron 6, turntable 7, and condenser 2; the input end of the PLC control system 9 is connected to the temperature detection device 3, concentration meter 4, and the output end is connected to the controller 5.

[0014] More specifically, the dyeing vat 1 has a top cover, and the top cover has a dye addition port, a water injection port and corresponding text ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com