Pre-buried casing type sleeper hoisting device

A hoisting device and a casing-type technology, applied in the directions of track, track laying, track maintenance, etc., can solve the problems such as the inability to meet the high-speed, economical and safety needs of the long-track track-laying machine, the occupation of working time, and the inability to realize sleepers, etc. To achieve the effect of simple structure, safe and reliable use, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

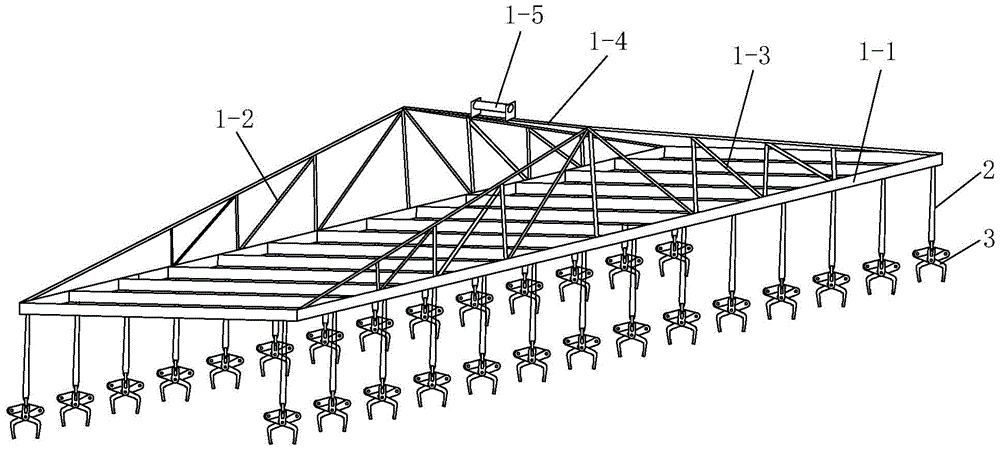

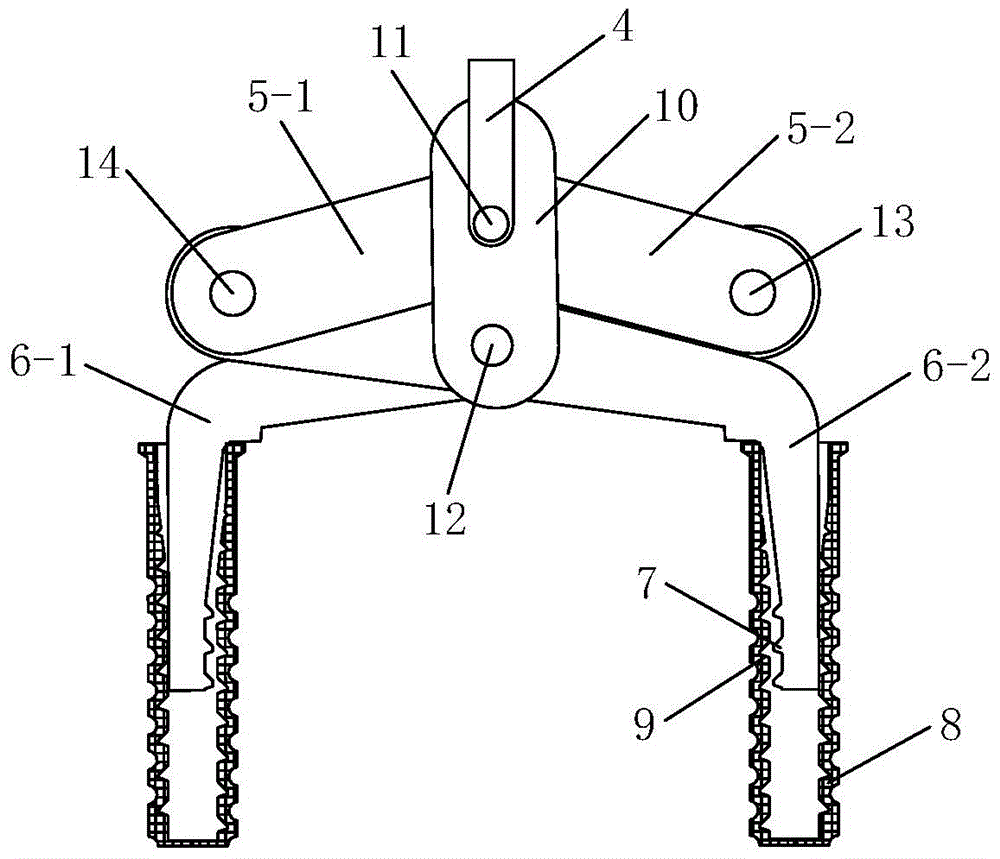

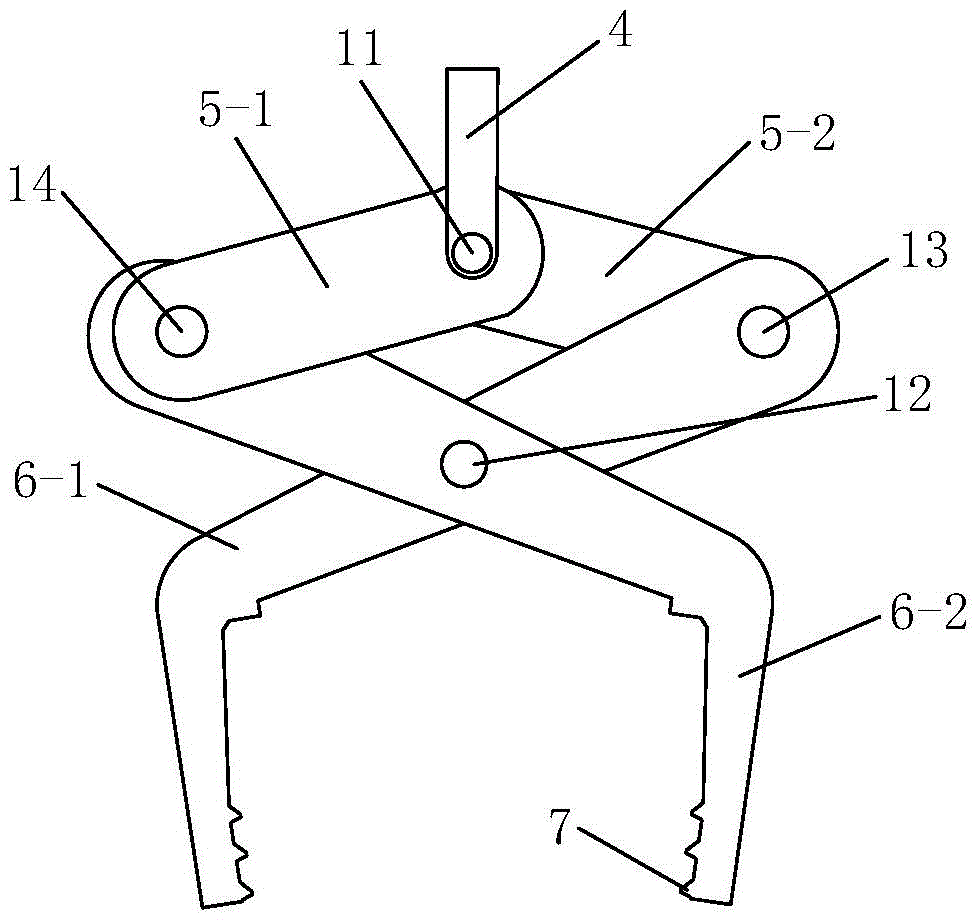

[0037] Such as Figure 1 to Figure 3 As shown, the present invention includes a hanger, and both sides of the bottom of the hanger are provided with hanging tongs 3, and the hanging tongs 3 are connected with the hanger by a sling 2, and the hanging tongs 3 include a suspension ring 4, a first connection Sheet 5-1, second connecting sheet 5-2, first clip 6-1 and second clip 6-2, the upper end of the first connecting sheet 5-1, the upper end of the second connecting sheet 5-2 and the lower end of the suspension ring 4 are hinged, the upper end of the first clip 6-1 is hinged to the lower end of the second connecting piece 5-2, and the upper end of the second clip 6-2 is connected to the first connecting piece 5-2. The lower end of 1 is hinged, the structure of the first clip 6-1 and the second clip 6-2 are the same and both are composed of an upper clip and a lower clip connected to the lower end of the upper clip, the first clip The upper clip of 6-1 and the upper clip of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com