Self-lubrication sealing structure for gear box

A sealed structure, self-lubricating technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of inability to achieve support bearing lubrication, inapplicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

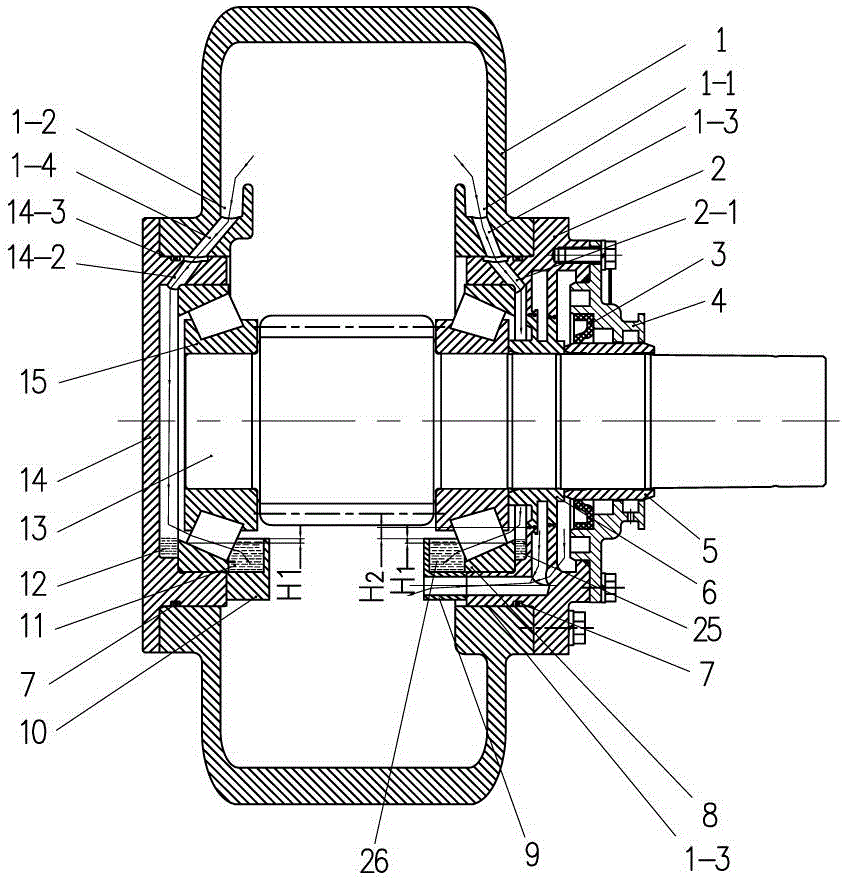

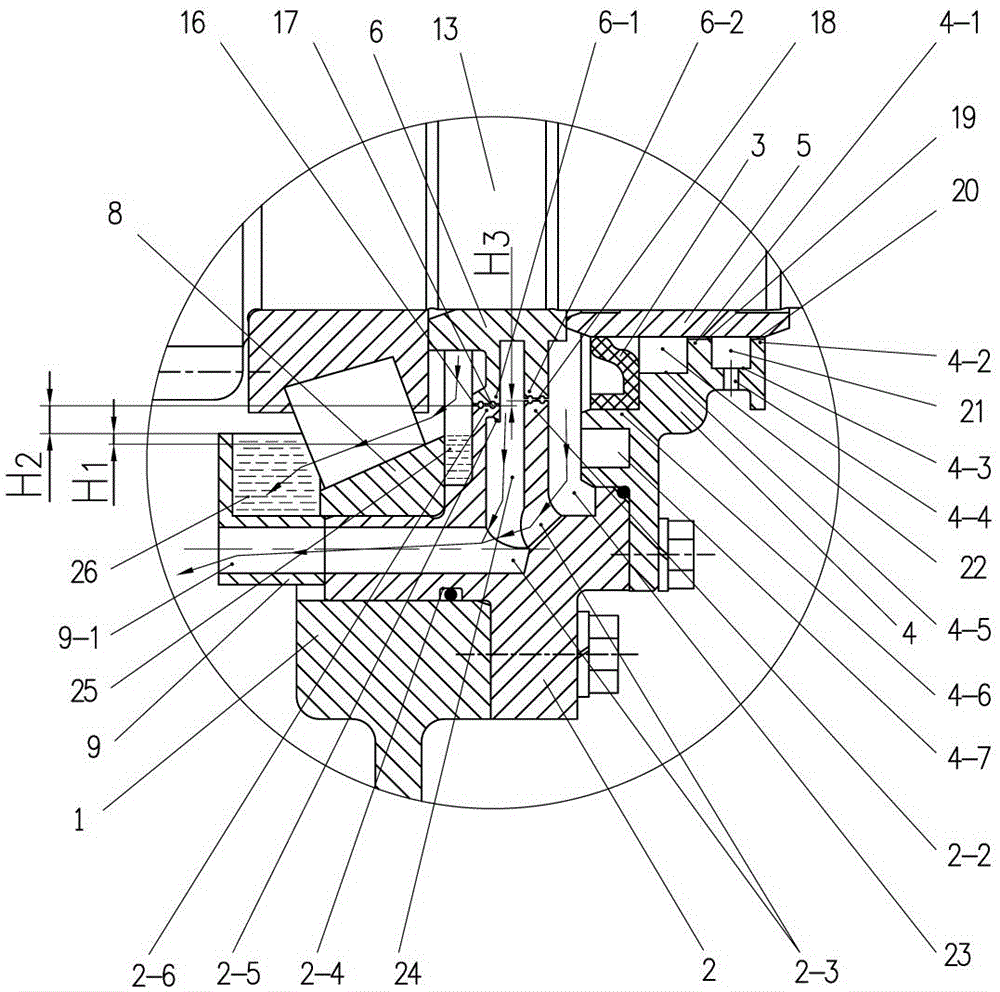

[0034] like figure 1 , 2 As shown, a gear box self-lubricating and sealing structure of the present invention includes a box body 1, a first bearing seat 2, a second bearing seat 14, a sealing ring 6, a sealing cover 4, a sliding sleeve 5, a skeleton oil seal 3, a first The support bearing 8, the second support bearing 15 and the gear shaft 13, the first bearing seat 2 and the second bearing seat 14 are respectively fixed on both sides of the casing 1, the first support bearing 8 and the second support bearing 15 respectively installed in the corresponding first bearing housing 2 and the second bearing housing 14, the gear shaft 13 is rotatably supported on the first support bearing 8 and the second support bearing 15,

[0035] On the two inner sidewalls of the box 1 and above the first bearing seat 2 and the second bearing seat 14, a first oil collecting groove 1-1 and a second oil collecting groove 1-2 are respectively provided,

[0036] The first bearing seat 2 has a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com