High-precision levelling device

A leveling device and high-precision technology, which is applied to the frame of the engine, supporting machines, mechanical equipment, etc., can solve the problems of no adjustment structure, vibration of the air conditioning unit, and level that cannot meet the requirements, so as to eliminate vibration and reduce construction difficulty , adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

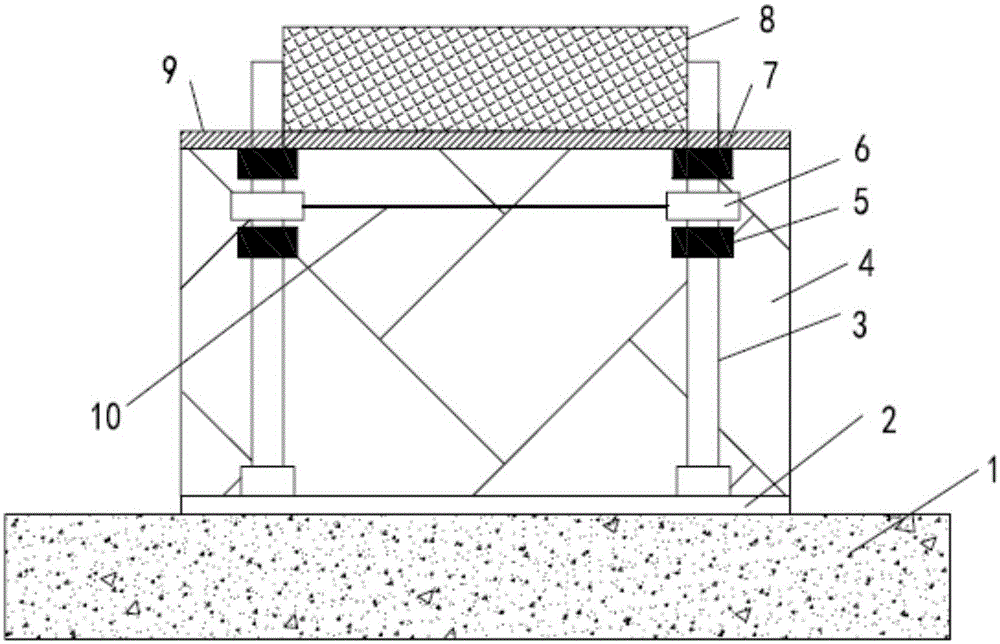

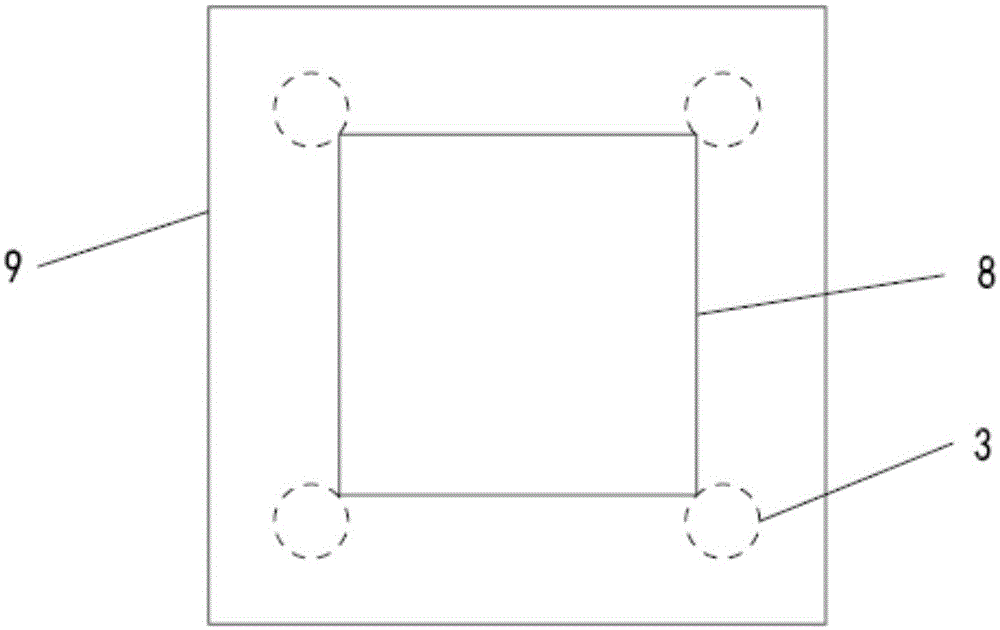

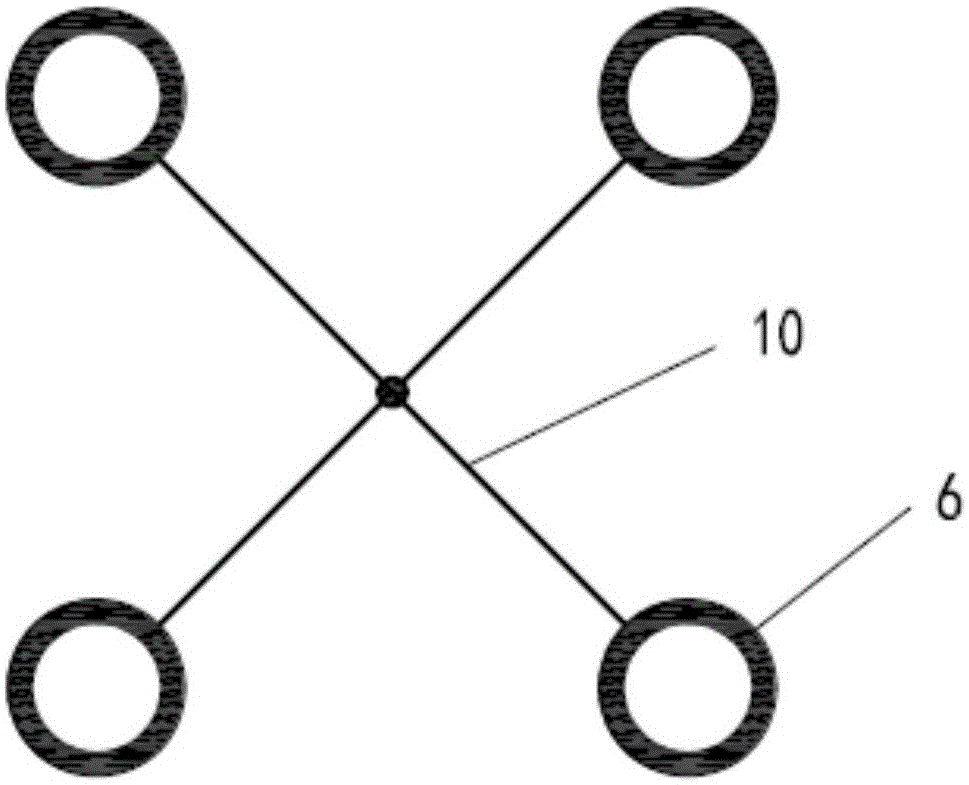

[0020] In order to describe in detail the technical content and structural features of the high-precision leveling device of the present invention, further description will be made below in conjunction with the embodiments and accompanying drawings.

[0021] The present invention takes four high-precision leveling components as an example:

[0022] Such as figure 1 , 2 , 3, 4, and 5, the high-precision leveling device of the present invention includes 4 high-precision leveling assemblies, and each high-precision leveling assembly consists of 4 bolts 3, steel plates 9, shock absorbing pads 8. Composition of stable load-bearing reinforcement components; 4 bolt holes are set on the steel plate 9, and 4 fixing nuts 7 are fixedly connected to the corresponding bolt holes at the bottom of the steel plate 9, and the steel plate 9 is set on the bolt 3 through the bolt holes and the fixing nuts 7, and the fixing nuts 7 and bolt 3 are connected by screws, and the whole length of bolt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com