Control system and control method of primary fan with liquid resistance speed regulator

The technology of a liquid resistance governor and control system is applied in the combustion method, the fuel burning in the molten state, lighting and heating equipment, etc., and can solve the problems affecting the stability and economic operation of the boiler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

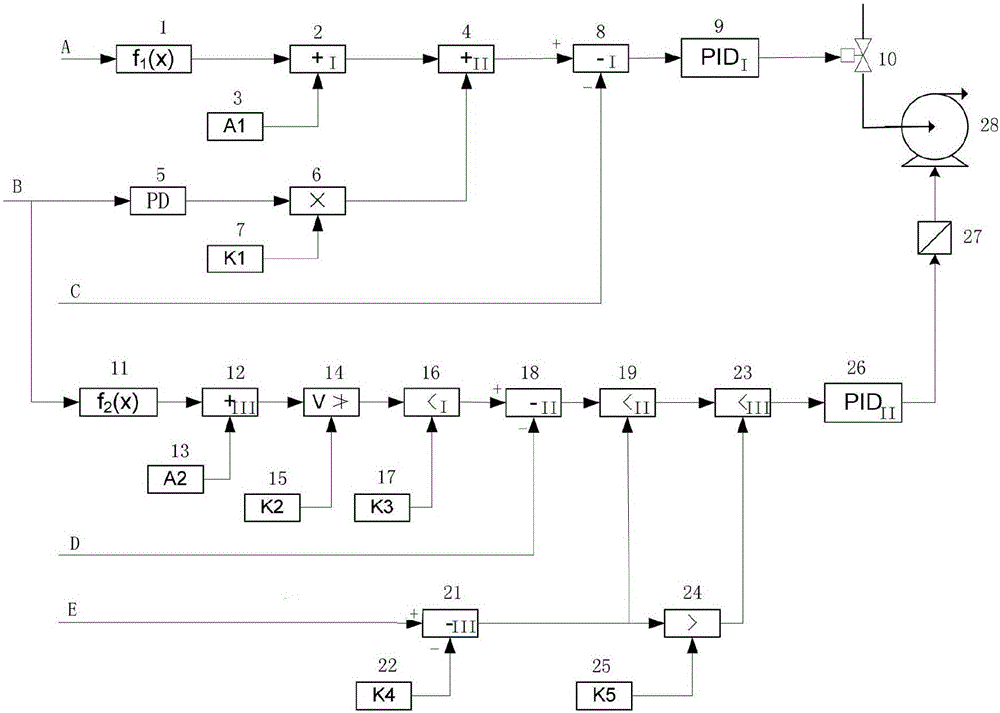

[0062] Such as figure 1 As shown, the primary fan control system with a liquid resistance governor in this embodiment includes a primary fan inlet baffle control device and a liquid resistance governor control device;

[0063] The primary fan inlet baffle control device includes a first function generator 1, a first adder 2, a first bias setter 3, a second adder 4, a PD controller 5, a multiplier 6, a first fixed parameter Setter 7, the first subtractor 8 and the first PID controller 9, the input end of the first function generator 1 is connected with the A input interface, the output end of the first function generator 1 is connected with the first of the first adder 2 The input terminal is connected, the output terminal of the first bias setter 3 is connected with the second input terminal of the first adder 2, the output terminal of the first adder 2 is connected with the first input terminal of the second adder 4, and the second The second input end of the adder 4 is conn...

Embodiment 2

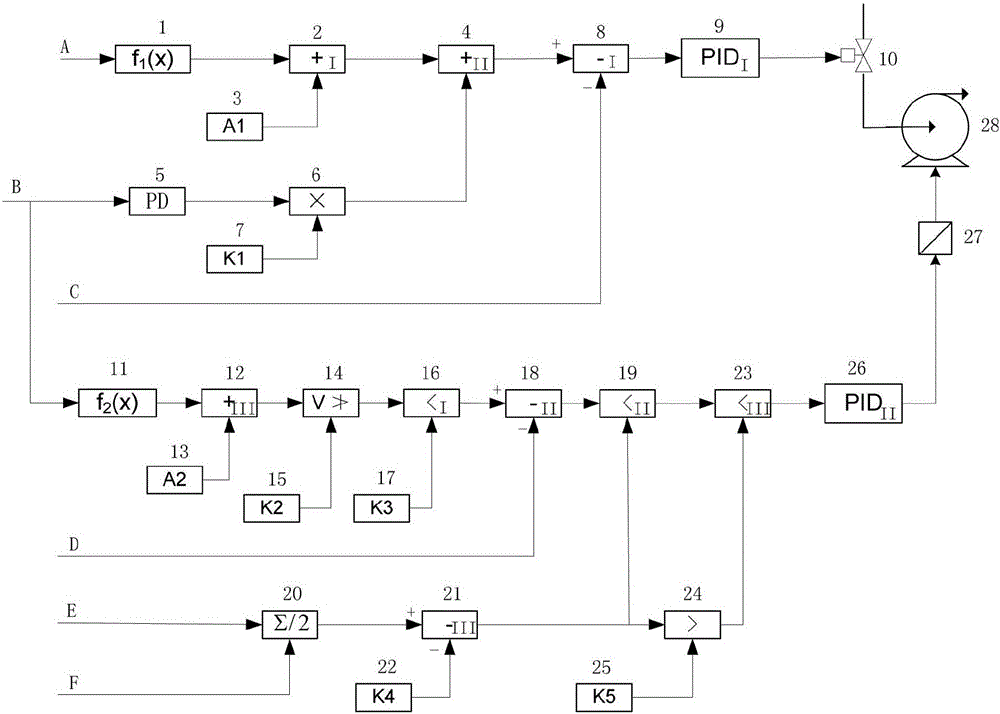

[0087] Such as figure 2 As shown, in the primary fan control system with a hydraulic resistance governor in this embodiment, the hydraulic resistance governor control device also includes an average value calculator 20, and the average value calculator 20 is provided with two input terminal, the E input interface of the hydraulic resistance governor control device is connected to the first input end of the average calculator 20, and the F input interface of the hydraulic resistance governor control device is connected to the second input terminal of the average calculator 20 The output end of the average calculator 20 is connected with the positive value input end of the third subtractor 21 . The E input interface described in this embodiment is connected to the primary fan inlet baffle opening value command of the primary fan control system with a liquid resistance governor, and the F input interface is connected to another primary fan control system with a liquid resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com