A ceramic drying device

A drying device and ceramic technology, applied in drying, dryer, progressive dryer and other directions, can solve the problems of low production efficiency, easy deformation, affecting the quality of ceramic products, etc., to achieve smooth operation and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

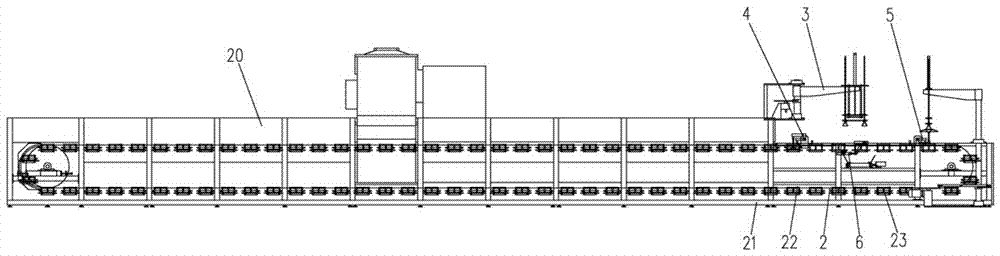

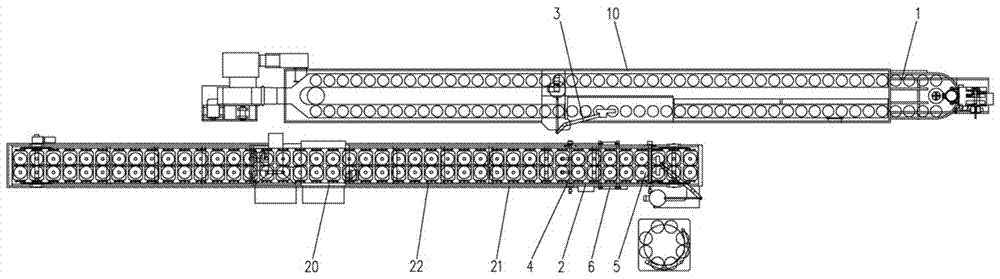

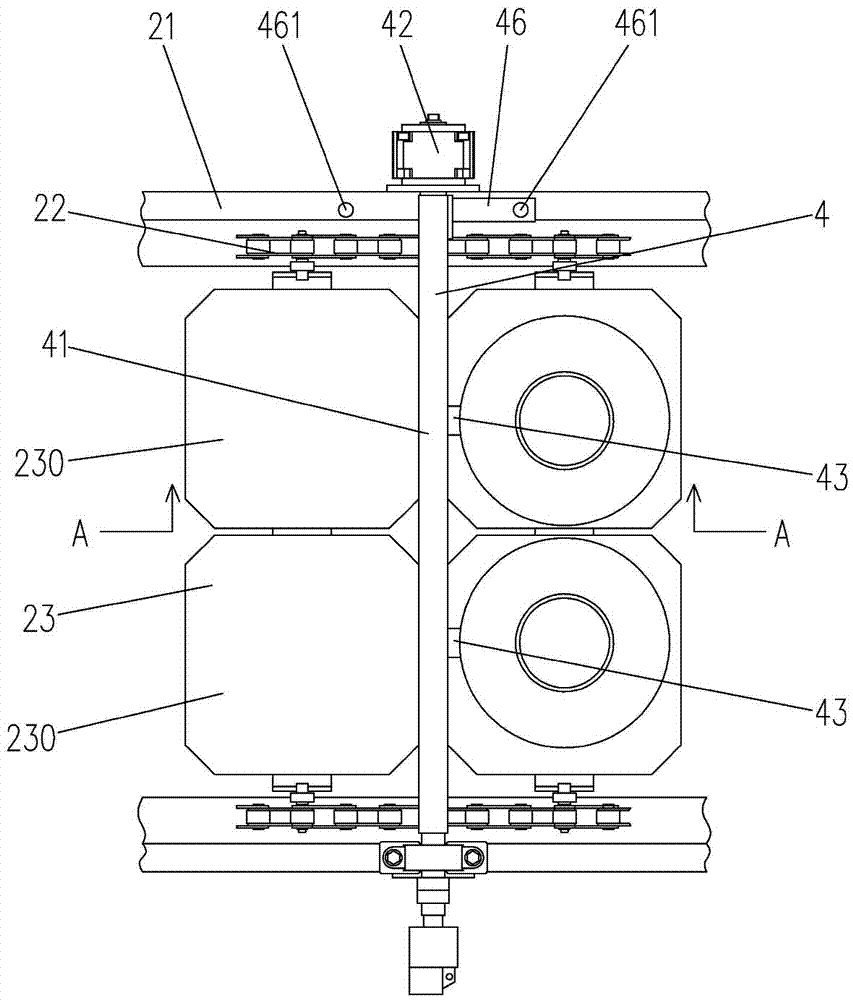

[0029] Such as Figure 1 to Figure 7As shown, a ceramic drying device includes a first transmission mechanism 1, a first drying system 10, a second transmission mechanism 2, a second drying system 20 and a transfer device 3, and the second transmission mechanism 2 is parallel to It is arranged on the side of the first transmission mechanism 1, the first drying system 10 and the second drying system 20 are respectively arranged above the first transmission mechanism 1 and the second transmission mechanism 2, and the transfer device 3 is arranged on the first drying system. On the top of the dry system 10, the second transmission mechanism 2 includes a frame 21 and an annular transmission rail 22 arranged on the frame 21. A number of hanging baskets 23 are evenly erected and distributed on the transmission rail 22, and each hanging basket 23 includes at least A placement unit 230, when the hanging basket 23 includes several placement units 230, several placement units 230 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com