A kind of standard substance of lead-containing paint coating and preparation method thereof

A standard substance and paint coating technology, applied in the field of lead-containing standard substances, can solve problems such as large interference and affect the accuracy of chemical testing of toys, and achieve the effects of high compatibility, fast speed and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

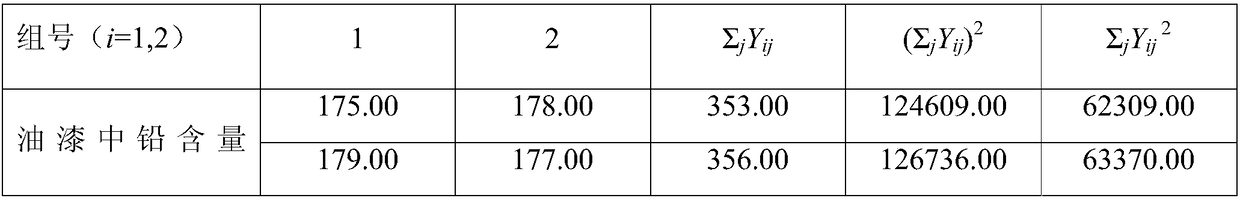

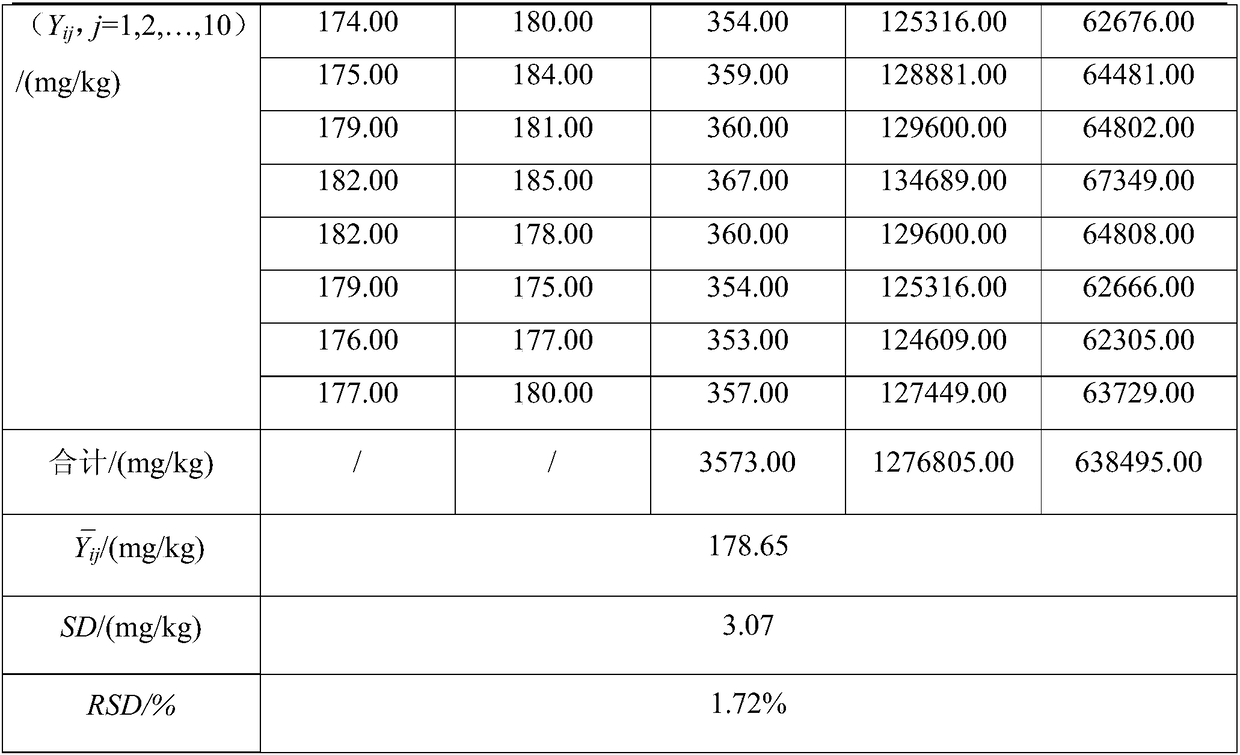

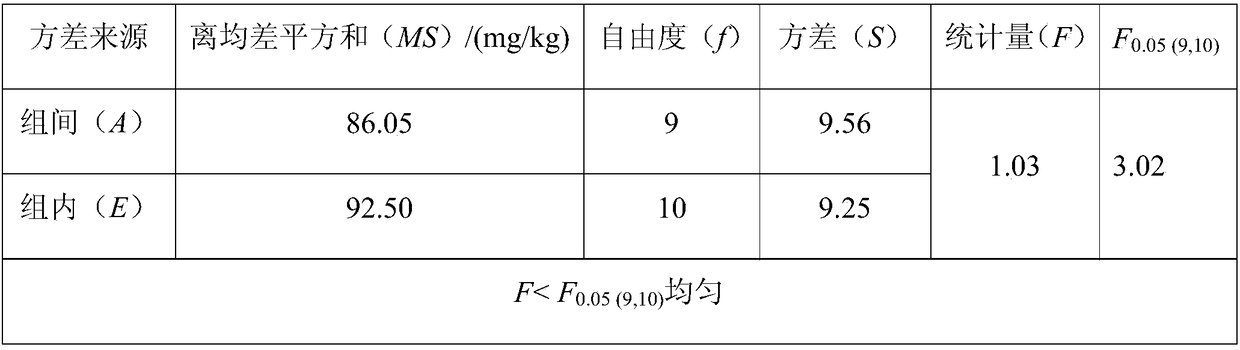

Examples

Embodiment 1

[0031] To make a dry coating reference material with a lead content of 200mg / kg:

[0032] First, take a small amount (about 5-10 grams) of pure yellow wet paint standard substance, apply it on a tempered glass sheet, weigh the mass before drying, then dry it in an oven for about 3 hours, weigh the mass after drying, and calculate the mass of the paint The solids content was 50%.

[0033] Weigh 4.0kg of wet paint after peeling (according to the calculation, the final solid content of simple paint is 2.0kg) and put it into the disperser, then add 1.06g of analytically pure lead naphthenate, and add a volume ratio of 1:1. Oil and water, start the disperser, stir at 120 rpm for 2-4 hours to get a wet paint mixture, this process is to make the lead naphthenate evenly diffuse into the paint. Then the obtained paint mixture is taken out from the disperser, and the paint mixture is sprayed on the tempered glass plate with a spray gun; the tempered glass plate is placed in a drying ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com