Design method of moving cam contour line during sine acceleration linear motion of roller center

A technology of sinusoidal acceleration and design methods, applied in calculation, special data processing applications, instruments, etc., can solve problems such as lack of reference methods, difficult design, and unreasonableness of cam contours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

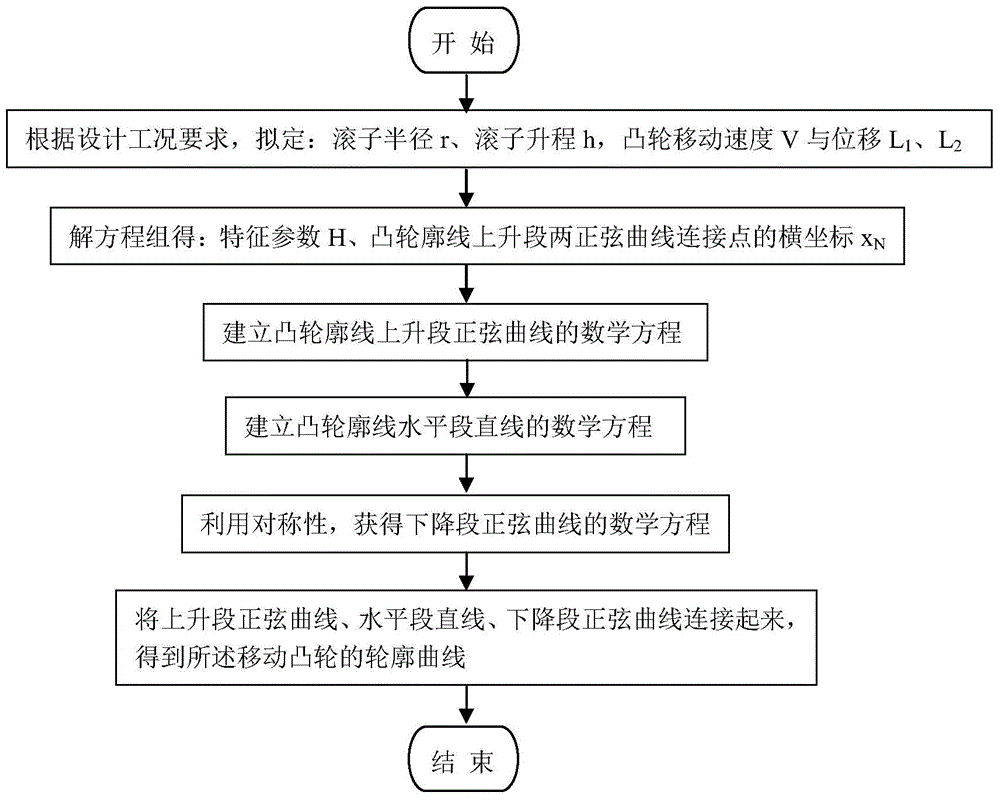

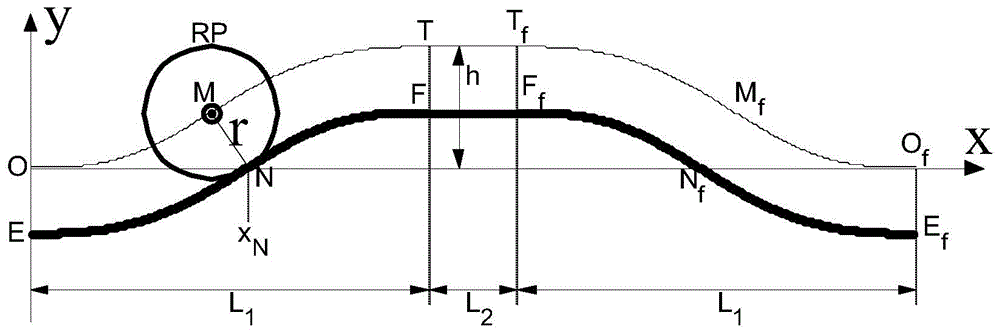

[0033] The implementation process of the method for designing the moving cam profile of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] 1) Start the system;

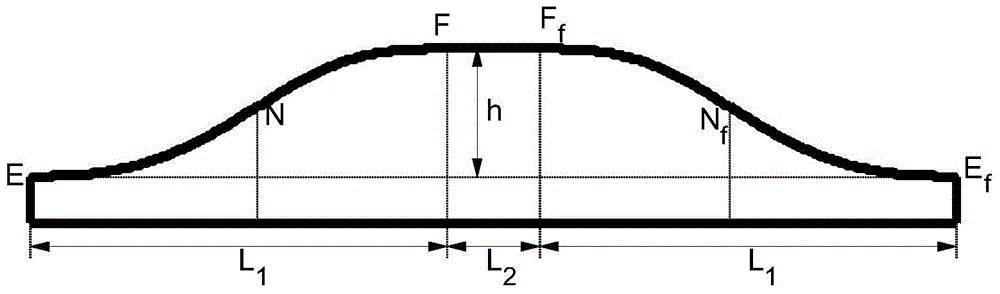

[0035] 2) According to the design conditions or the actual requirements of the production site, formulate the radius r of the roller, the lift h of the roller, the moving speed V of the cam, and the displacement L of the cam corresponding to the lift h of the roller 1 , and the horizontal segment straight line FF f Corresponding cam displacement L 2 ;

[0036] 3) Take the initial rising point of the roller center as the origin O of the coordinate system, the opposite direction of the cam movement is the x direction, and the upward direction perpendicular to the cam movement direction is the y direction. The acceleration equation of the center of the roller in the moving part---moving cam mechanism is a sine function:

[0037] a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com