Method and device for active noise reduction for industrial noise treatment

An industrial noise and noise reduction technology, applied in the direction of sound-generating equipment, speech analysis, instruments, etc., can solve the problems of weakening driving force, high price, losing the public market, etc., to avoid the influence of phase difference offset, save electrical devices, simplify The effect of mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

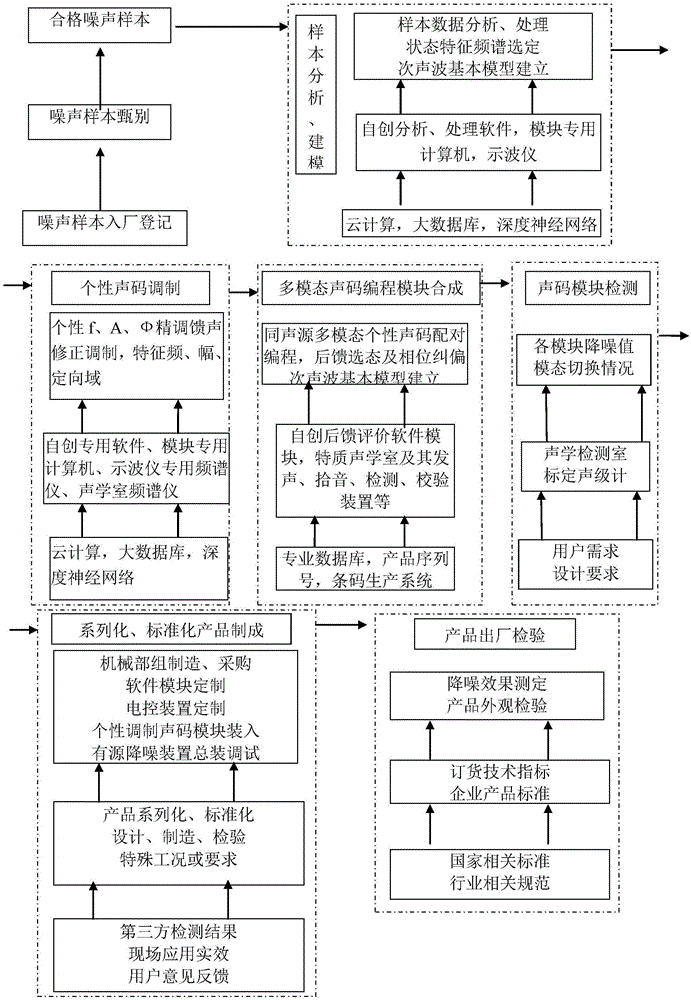

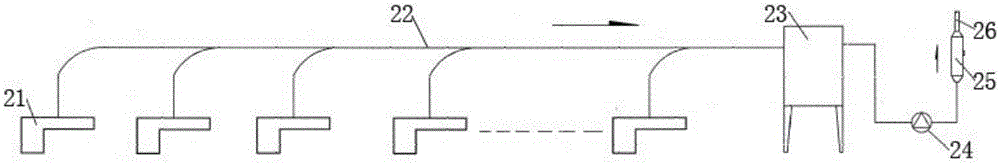

[0057] Such as Figure 1-3 As shown, the method of the present invention is described as an example with the blower fan noise control for industrial dust removal system:

[0058] According to production needs, there are at most N production equipment 21 in production, and at least one production equipment 21 is in operation. The system piping system 22, dust collector 23, fan 24, active noise reduction device 25 and exhaust port 26 are designed to meet the production and operation needs of multiple working conditions. According to the production status, there are limited N kinds of working conditions for the fan 24, that is, there are N kinds of noise spectrums, but the noise is relatively stable under the same working conditions. The noise measured at the exhaust port is the exhaust noise, which includes the composite result of noise waves in complex processes such as the combined superposition and interference of various noises in the system.

[0059] 1. Actual measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com