Combine

A combine harvester and receiving port technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problem of not taking into account the main factors such as driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

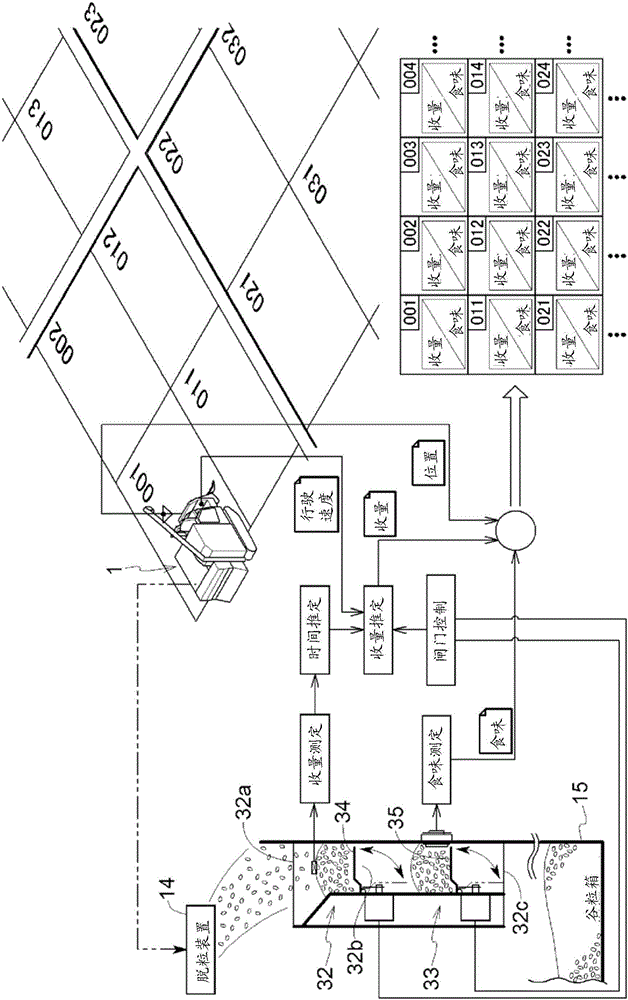

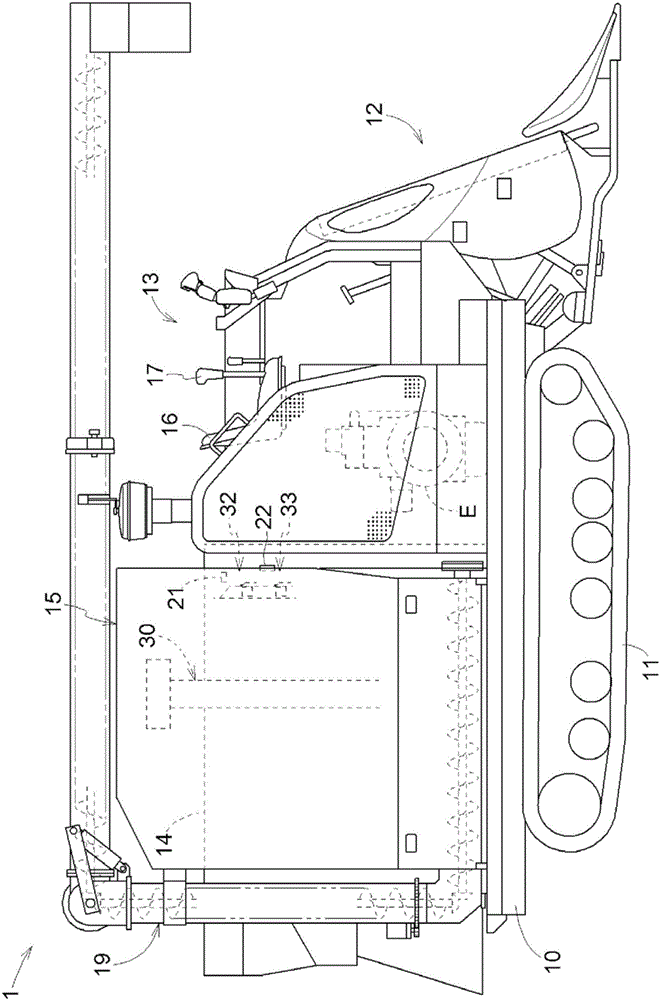

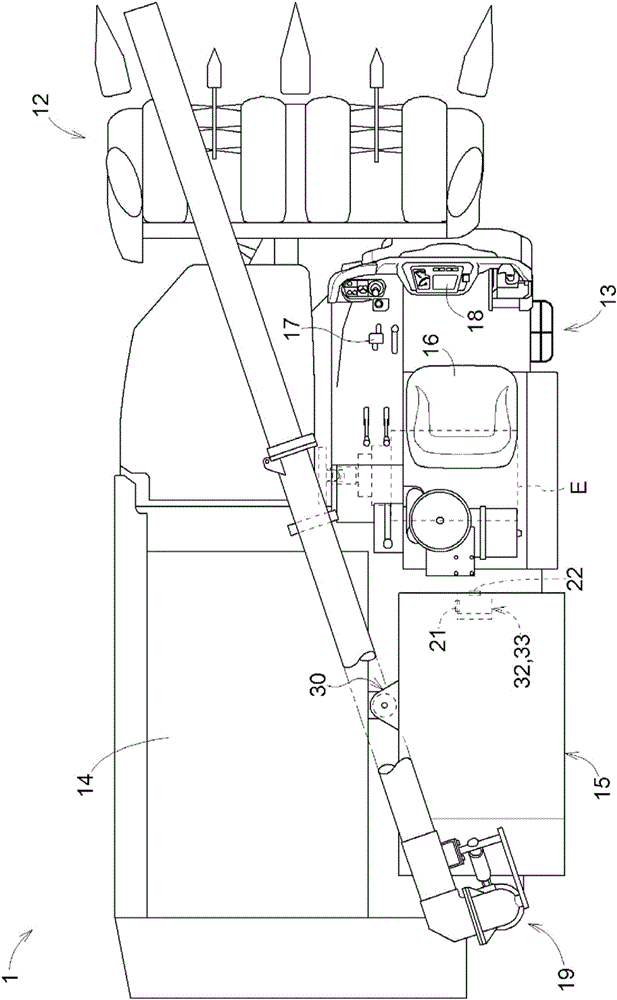

[0029] Before describing the specific embodiment of the combine harvester of the present invention, use figure 1 The basic principles characterizing the present invention will be described.

[0030] exist figure 1 In the example of , the combine harvester 1 harvests the grain stalks of wheat and rice while traveling in the field, and the detached grains are stored in the grain tank 15 mounted on the combine harvester 1 . At this time, in this combine harvester 1, the quantity of the grain supplied to the grain tank 15 with the lapse of time, that is, the yield is measured. Furthermore, the food taste (moisture content, protein, etc.) of this grain can also be measured.

[0031]In order to measure the yield of grains, a yield measuring container 32 is provided on the grain tank 15, and the yield measuring container 32 has a yield receiving port 32a for receiving at least a part of the grains supplied to the grain tank, and an outlet for discharging. The yield discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com