Impeller for fan

A blower and impeller technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of insufficient lightening effect, insufficient lightening effect, large specificity of thin steel plate, etc., and achieve strength improvement , Product cost reduction, low noise and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

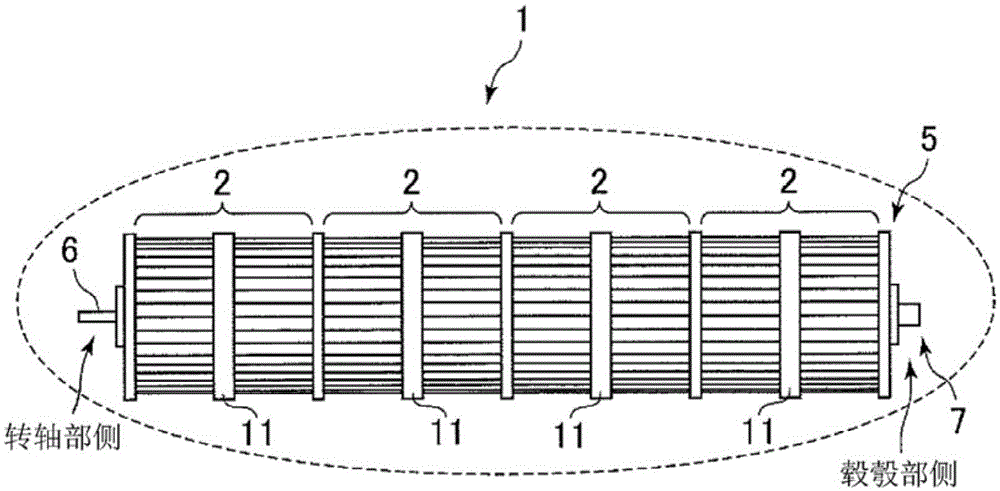

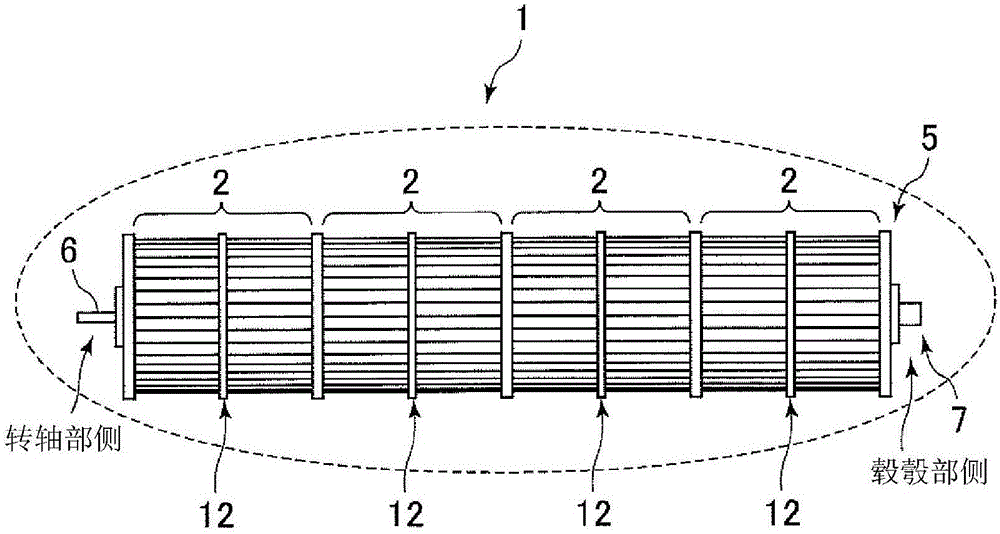

[0050] Structure of the impeller of the present invention

[0051] of the present invention figure 1 The impeller 1 is composed of several figure 2 The constituent unit 2 of the impeller, the disc-shaped fixed plate 5 at the hub hub side, the rotating shaft part 6 and the hub hub part 7 constitute. The rotating shaft portion 6 is attached to the disk-shaped member 3 of the constituent unit 2 at one end portion of the impeller 1 . The hub-side disk-shaped fixing plate 5 is attached to the blade member side of the constituent unit at the other end of the impeller 1 . The hub portion 7 is provided on the hub-side disk-shaped fixing plate 5 .

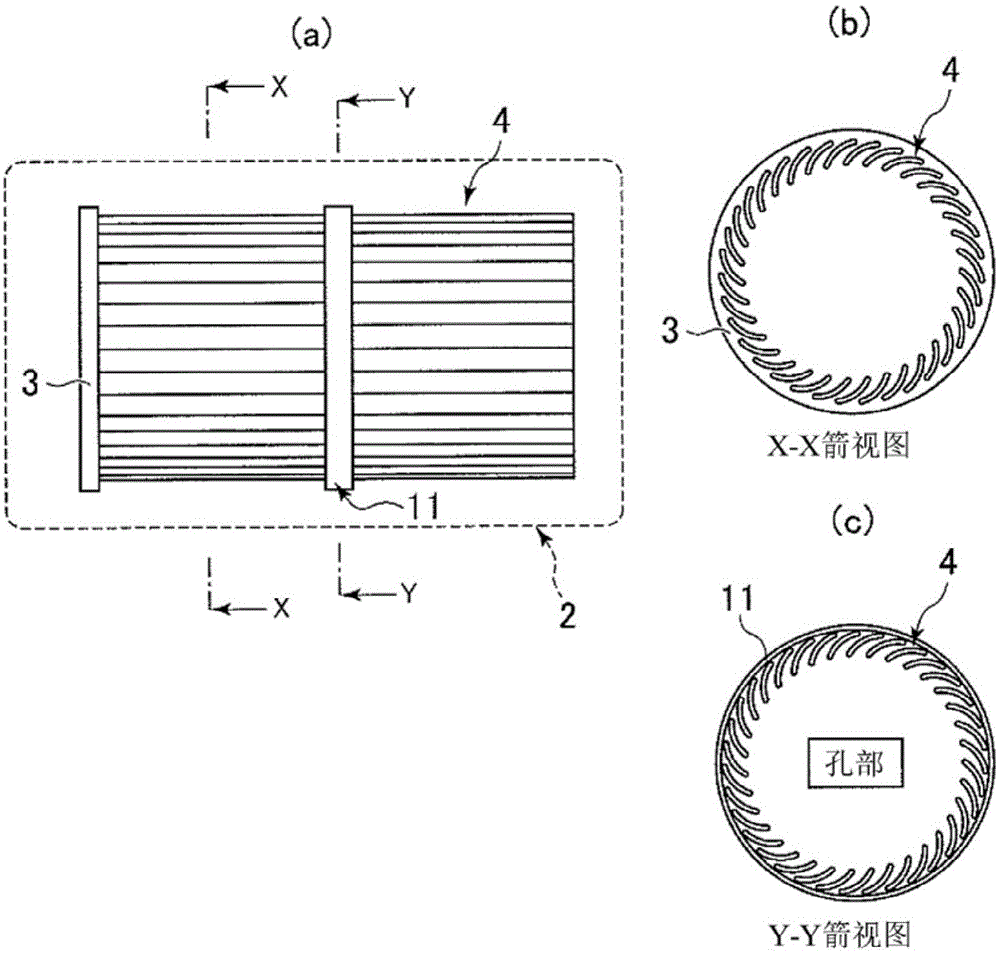

[0052] Structure of blade member (constituent unit 2)

[0053]The constituent unit 2 of the impeller 1 is composed of a disk-shaped member 3 , blade members 4 and a reinforcing ring 11 . As the material, synthetic resins such as AS resin, ABS resin, PS resin, and PP resin can be used. The resins described here are just examples, an...

Embodiment

[0059] In this embodiment, the constituent unit 2 and the hub-side disk-shaped fixing plate 5 are manufactured using AS resin material which is a synthetic resin. The blade parts that make up the unit are figure 2 In the form shown, the average thickness was 0.4 mm, the length was 160 mm, and the number of sheets was 35. In addition, the diameter of the constituent unit was set to 106 mm at the outermost portion of the blade member 4 . In addition, a reinforcement ring 11 is integrally formed at a substantially central portion in the longitudinal direction of the blade member constituting the unit (the center position of the blade member with a length of 160 mm). Such a constituent unit is integrally molded from the raw material of the above-mentioned material by injection molding. In addition, by ultrasonic fusion, four such constituent units and the hub-side disk-shaped fixing plate 5 made of the same material as the constituent units are bonded to produce figure 1 The i...

Embodiment 2

[0073] This example is made by changing the material of Example 1 in the following manner, and other conditions are set to be the same. Therefore, the shape of the impeller of this embodiment and the shape of its constituent units are consistent with figure 1 and figure 2 same.

[0074] The materials of the constituent units 2 of the impeller 1 and the hub-side disc-shaped fixing plate 5 will be described. As the material, a composite material of AS resin and glass fiber, a composite material of ABS resin and glass fiber, a composite material of PS resin and glass fiber, or a composite material of PP resin and glass fiber can be used. In this case, the glass fiber content is preferably 10% to 40% by weight of the whole, and more preferably 10% to 30% of the whole. If the content of the glass fiber exceeds 40% by weight of the whole, there is a possibility that the blade parts constituting the unit may be defectively formed. In addition, if the glass fiber content is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com