Farming method of returning straw to the field in the rotation system of flue-cured corn and tobacco

A technology for flue-cured tobacco stalks and corn stalks, which is applied in the agricultural field, can solve the problems that tobacco fields do not obtain organic matter and nutrient elements, soil is not improved, and organic fertilizer resources are wasted, so as to promote sustainable development of production and improve soil microbial biomass and enzymes. Activity, the effect of reducing the spread of pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In a flue-cured tobacco experimental base in a certain tobacco area, an application test of the method of corn and flue-cured tobacco rotation, straw rot promotion, no-tillage ditch burial and return to tobacco planting soil was carried out.

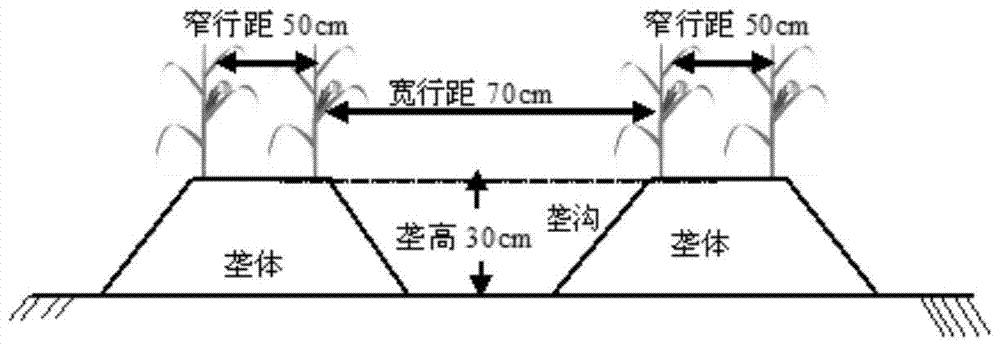

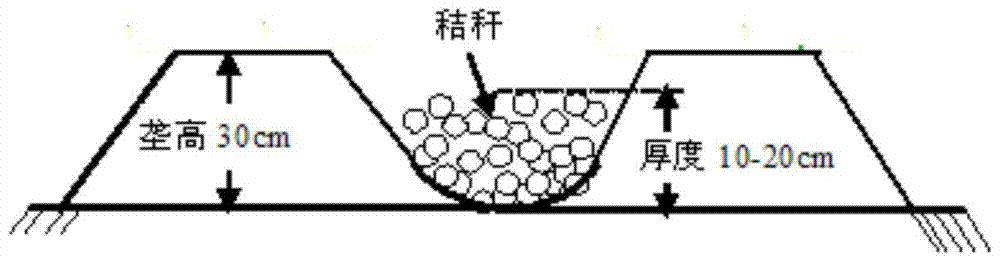

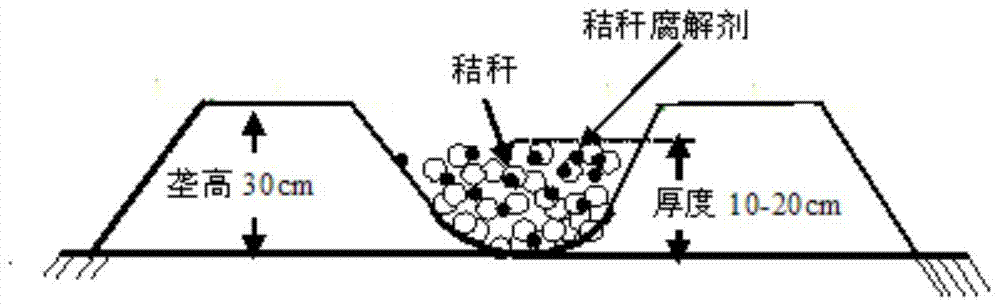

[0046] Corn is sown in mid-May of the first year, using wide and narrow rows, 70 cm wide and 50 cm narrow, and the corn matures in early August. In mid-October, cut the corn stalks into small pieces of 50-80cm, spread them in the original furrows, and use 650kg / mu. Use 2 kg / mu of organic waste fermented koji produced by Beijing Jingpuyuan Bioengineering Co., Ltd. to spread evenly on the corn stalks, and then cover with soil. The soil covering method is to cut the original ridge from the middle, make the soil on the ridge fall to the direction of the furrow, and bury the corn stalks. The thickness of the covering soil is about 10cm. After covering with soil, make the furrow slightly concave.

[0047] In mid-April of the second ye...

Embodiment 2

[0071] Example 2——The labor comparison of different soil improvement measures

[0072] It can be known from Table 8 that compared with the traditional corn flue-cured tobacco wheel, the present invention can save labor by 3.5 per mu, mainly for corn and flue-cured tobacco land preparation. Compared with the method of the invention 201510175054.6, the present invention can save labor by 3 per mu, among which 1.5 per mu can be saved by corn land preparation, and 1.5 per mu can be saved by not planting green manure.

[0073] Table 8 Labor comparison of different soil improvement measures

[0074]

[0075] Note: ① is the method of invention 201510175054.6; ② the method of the present invention; ③ traditional method in mountainous areas

Embodiment 3

[0076] Example 3——Comparison of the biological return amount of different soil improvement measures

[0077] It can be seen from Table 9 that compared with the traditional corn flue-cured tobacco wheel, the present invention increases the amount of straw returning to the field by 1050kg / mu, mainly corn and flue-cured tobacco straw returning to the field. Compared with the method of the previous application 201510175054.6, the present invention can increase the amount of straw returning to the field by 500kg / mu, mainly the amount of flue-cured tobacco straw returning to the field and some large amounts of corn straw; and the amount of returning green manure to the field is reduced by 1500kg / mu.

[0078] Table 9 Comparison of biological return amount of different soil improvement measures

[0079]

[0080] Note: ① is the method of invention 201510175054.6; ② is the method of the present invention; ③ is a traditional method in mountainous areas; ④ is the amount of fresh grass....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com