Continuous noodle press and noodle pressing method

A noodle press, continuous technology, applied in the field of continuous noodle press and noodle press, can solve the problems of messy gluten structure, low quality of noodle products, loose and non-agglomerated, etc., and achieve the effect of improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

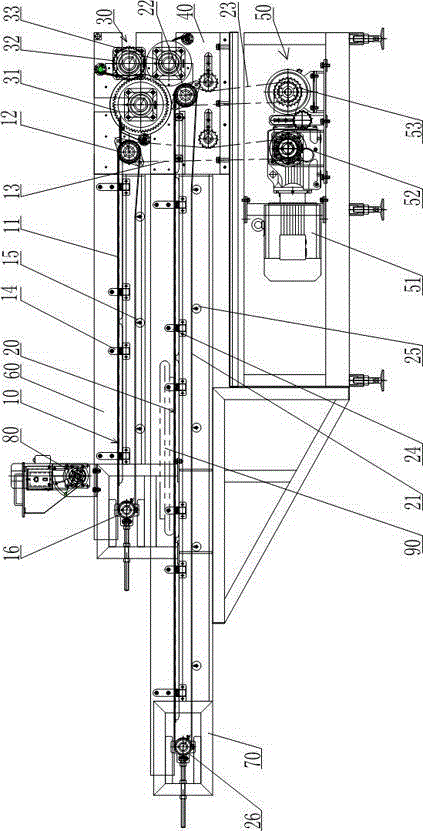

[0036] refer to figure 1 Shown, this embodiment is a kind of continuous noodle press machine, and this noodle press machine comprises upper layer belt assembly 10, lower layer belt assembly 20, pressing roller assembly 30, frame assembly 40, power assembly 50, noodle belt entrance 60 and noodle The belt outlet 70, the programmable controller, and the power combination 50 respectively drive the upper and lower belt combinations and the pressing roller combination under the control of the programmable controller to press the surface.

[0037] The specific transmission process is as follows:

[0038] The upper belt assembly 10 comprises an upper belt 11, a first driven pulley 12 and a first chain 13;

[0039] The lower belt assembly 20 includes a lower belt 21, a second driven pulley 22 and a second chain 23;

[0040] The power combination 50 includes a speed reducer, an electromagnetic clutch 51, a first drive sprocket 52, and a second drive sprocket 53;

[0041] The first dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com