Tea drying machine

A technology of tea dryer and drying box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

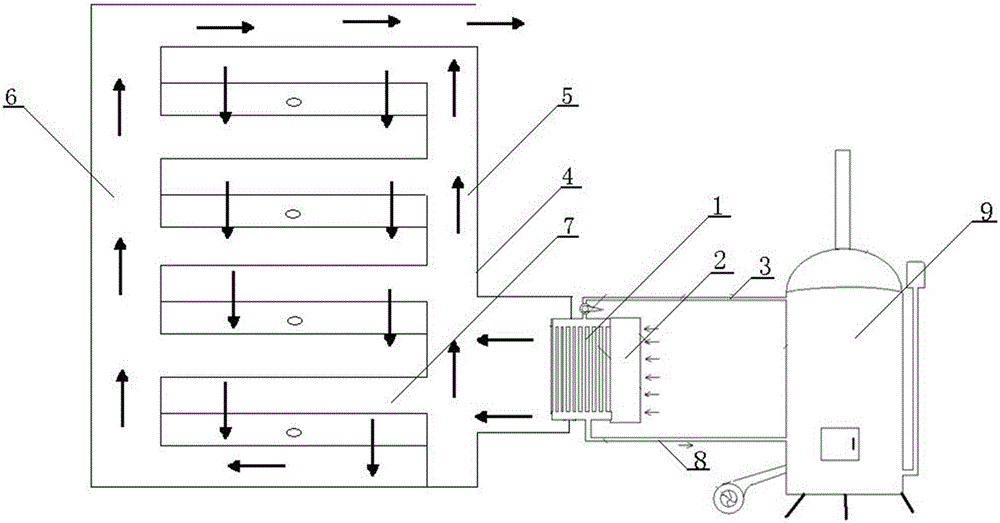

[0017] Such as figure 1 As shown, the tea drying machine of the present invention includes a drying box 4 , a drying chamber 7 arranged in the drying box 4 and a heating device connected to the drying box 4 .

[0018] The right side of the drying box 4 is provided with a vertical hot air channel 5, the left side of the drying box 4 is provided with a vertical air outlet channel 6, and a plurality of drying chambers 7 are vertically distributed in the drying box 4. , the hot air passage 5 and the air outlet passage 6 are connected through the drying chamber. There are 3 drying chambers, placed side by side and vertically, and the different drying chambers are connected in parallel. There is an inlet on the right side of the drying chamber 7, which is directly connected to the hot air passage 5, the lower end of the drying chamber 7 has an outlet, and the outlet directly communicates with the air outlet channel 6.

[0019] The heat supply device includes a boiler 9, a heat exch...

Embodiment 2

[0024] The difference between embodiment 2 and embodiment 1 is that there are 8 drying chambers in embodiment 2, which are connected in parallel. In order to meet the heat requirements of more drying chambers, oil is used as the medium for heating.

[0025] The application method of the present invention is:

[0026] Before starting work, add medium in the boiler 9, the added medium is at least 50 centimeters higher than the high-temperature liquid delivery pipe 8. Then start heating, and at the same time turn on the pump. Under the action of the pump, the medium enters the high-temperature liquid delivery pipe 8, then enters the heat exchanger 1, then enters the low-temperature liquid return pipe 3 and finally returns to the boiler 9. When the liquid enters the heat exchanger 1 , due to the action of the electric fan, the cold air is heated and enters the hot air channel 5 , passes through the drying chamber in parallel and finally returns to the outside through the air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com