Hickory nut shell breaker

A pecan and shell breaking machine technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of pecan shell breaking without a shell breaking adjustment device, unable to adjust the shell breaking strength, and the shell breaking machine stuck. Achieve the effects of good shell breaking quality, high shell breaking efficiency and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the structure of the present invention is described in detail with reference to the drawings.

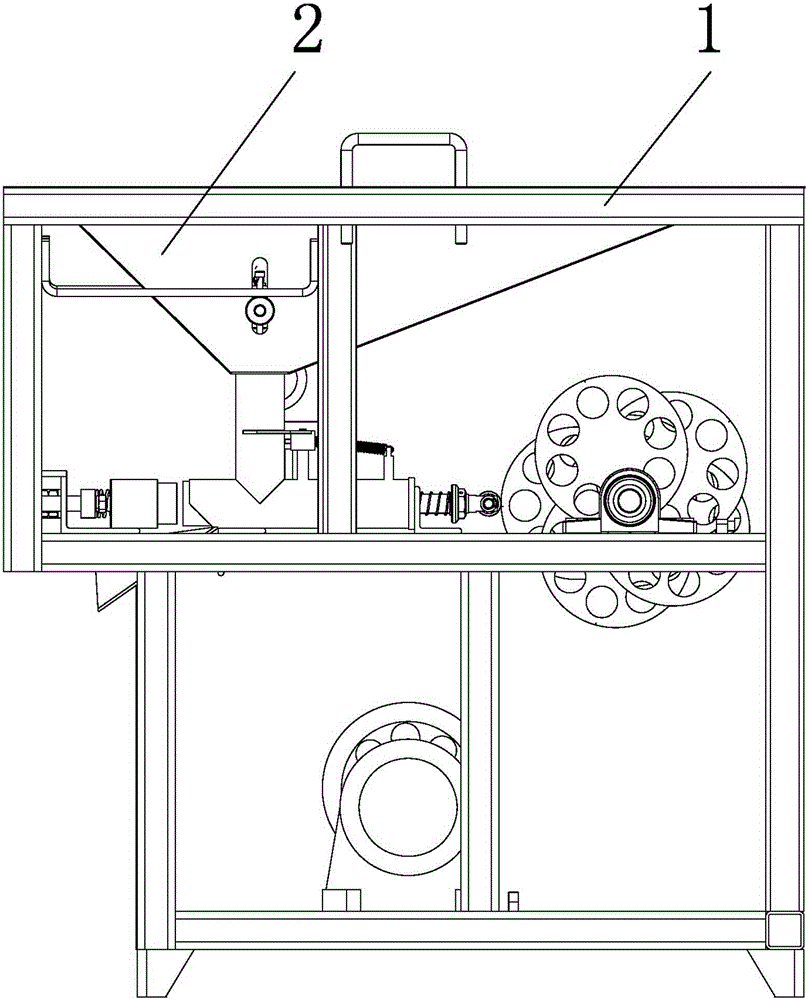

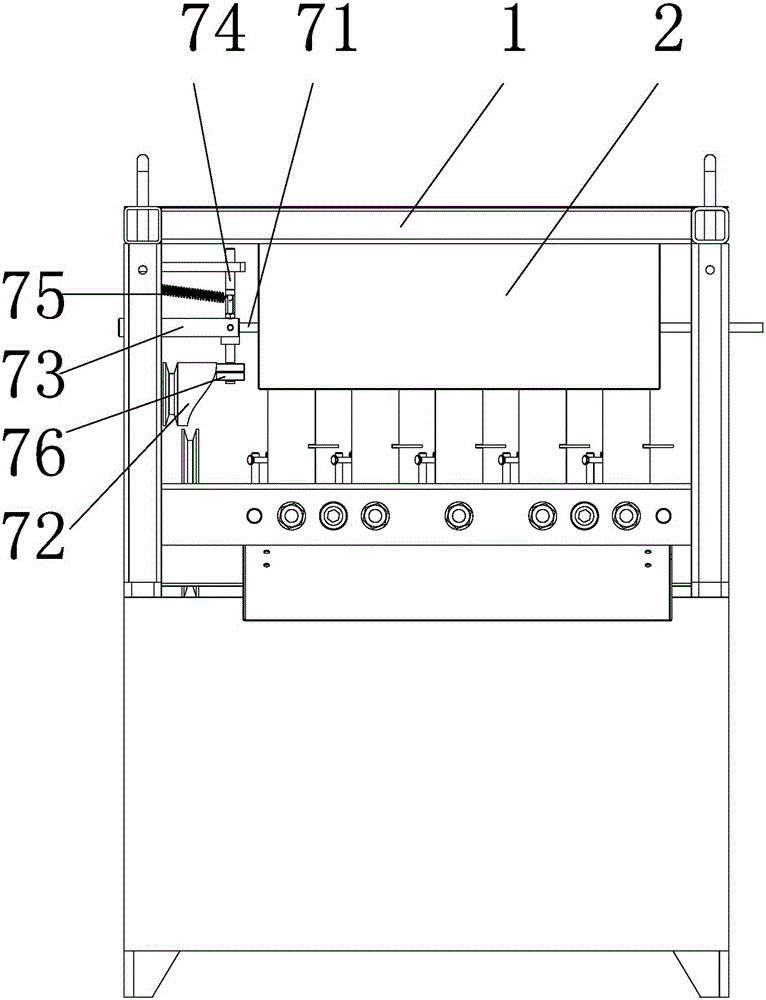

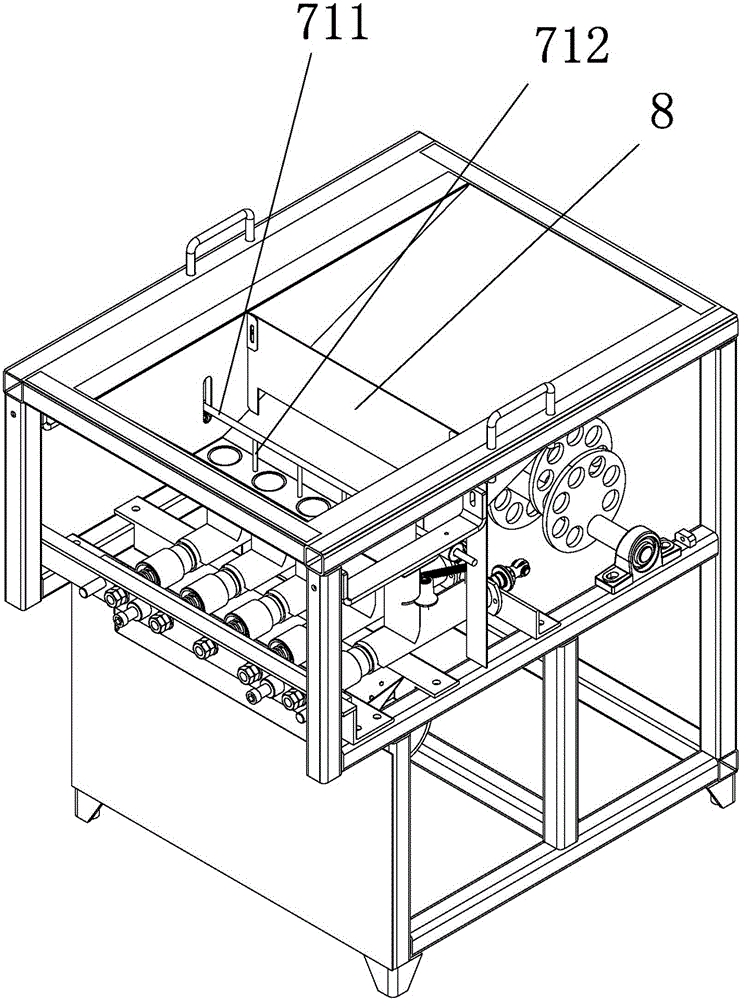

[0033] As shown in the figure, the hickory nut shell breaking machine provided by the present invention constructs the hickory nut shell breaking machine, includes a frame 1 and a feed hopper 2, and also includes the following:

[0034] The drive mechanism includes a camshaft 32 with a plurality of eccentric cams 31 . The outer contour shape of the eccentric cam 31 is circular, and the eccentric cam 31 is equidistantly arranged along the axial direction of the camshaft 32 and arranged in a spiral misalignment along the circumference of the camshaft 32; the eccentric cam 31 is provided with a plurality of first through holes 33. A camshaft 32 is installed in the hole 33 .

[0035] The shell-breaking mechanism includes a gun rod 41 that is intermittently contacted and driven by the eccentric cam 31. The gun rod 41 is arranged in the hollow gun barrel. The g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap