Vertical roll grinding mill

A vertical roller and mill technology, applied in the field of vertical rollers, to achieve the effects of reducing waste consumption, reducing surface area, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] [experimental device]

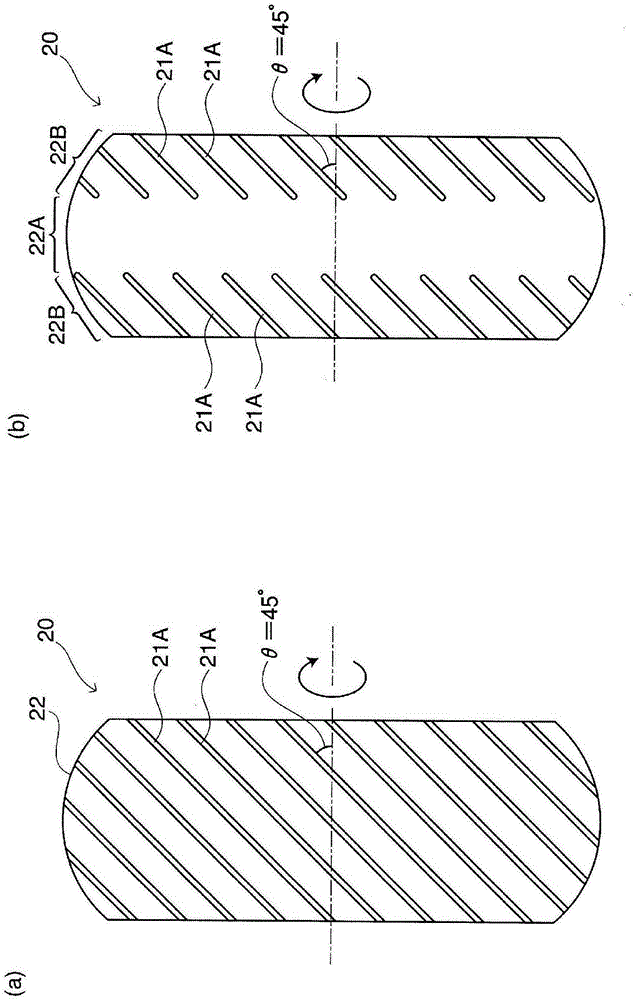

[0068] In order to investigate the effectiveness of the present invention, a vertical roller mill, which is a small experimental pulverizer similar to a LOESCHE mill with trapezoidal rollers, was fabricated. like Figure 6 As shown, this pulverizer has a structure in which pulverizing rollers 2 face each other on the outer peripheral surface of a horizontal rotary table 1 as a base member. The crushing roller 2 is a truncated cone-shaped vertical roller with the large-diameter side facing the outer peripheral side and the small-diameter side facing the center side, and is inclined so as to be horizontal to the opposing surface of the rotary table 1 . Since it is a test machine, the number of objects of the roll was set to one.

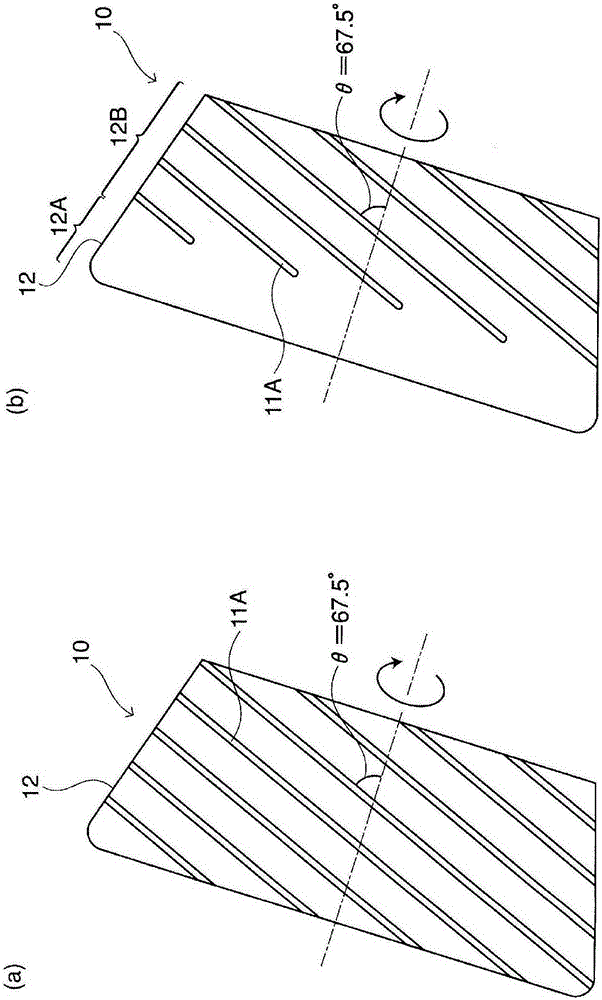

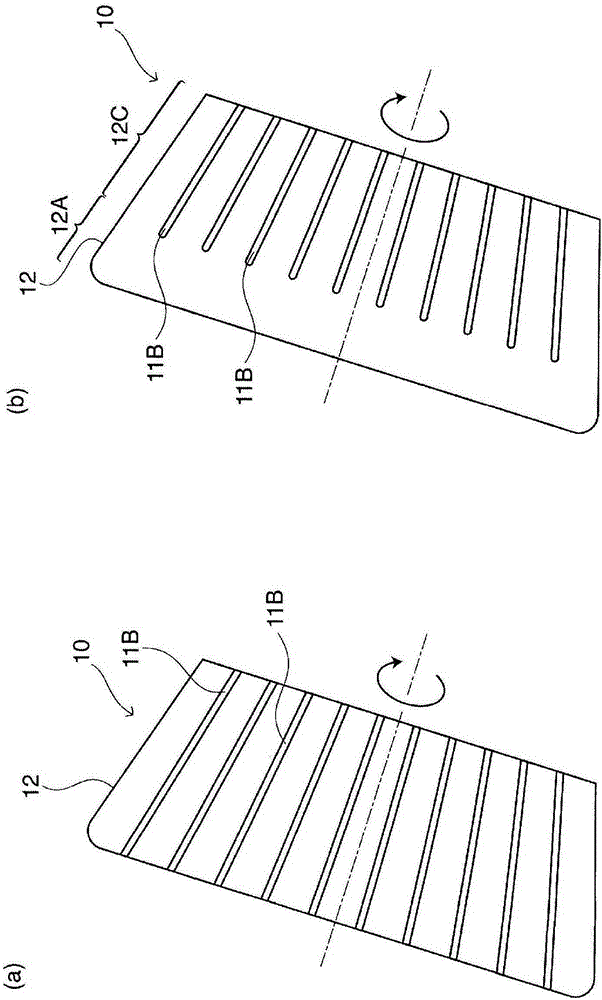

[0069] A plurality of spiral grooves 7 are provided on the outer peripheral surface of the crushing roller 2 . The plurality of spiral grooves 7 discharge the ground material from the center of rotation toward the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com