Inner arc turning device

A technology of turning machining and inner arc, which is used in feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high processing cost, inability to guarantee accuracy, low processing efficiency, etc., to ensure the accuracy and reliability of processing. performance, saving input and processing costs, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

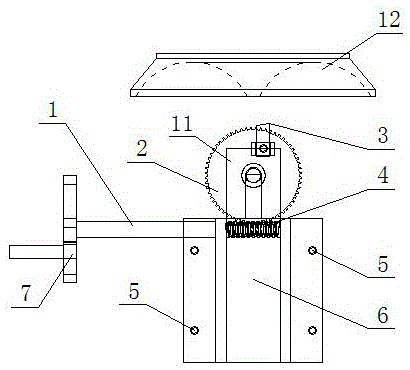

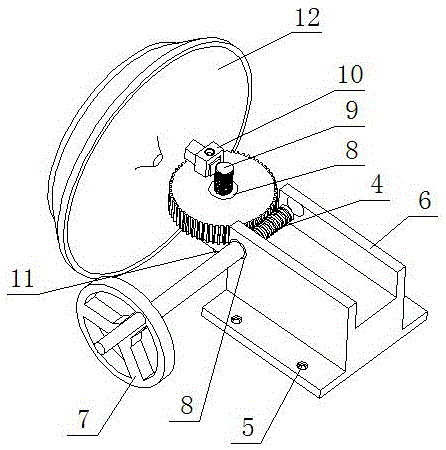

[0013] This inner arc turning processing device is made of rocker arm shaft 1, worm gear 2, cutter 3, worm screw 4, fixed base 6, rocker arm 7, worm gear shaft 9, knife rest 10 and worm gear shaft fixed block 11; Concave, four installation holes are made on both sides of the lower part of the fixed base 6, and the fixed base 6 is fixed and installed in the original screw holes on the middle carriage of the lathe through four installation holes and installation screws, and the fixed base 6 is connected with the middle carriage of the lathe Synchronized linear motion. A rocker shaft 1 is installed above one end of the fixed base 6 through a bearing 8, and a worm 4 is made on one end of the rocker shaft 1; A worm gear shaft 9 is fixedly installed on the fixed block 11, and a turbine 2 is installed through a bearing 8 on the worm gear shaft 9;

[0014] The working process of this inner arc lathe processing device is as follows: earlier the inner arc workpiece 12 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com