Saddle with non-return device and non-return valve

A saddle and backstop technology, applied in the fields of check valves, saddles, and pipeline valves, can solve the problem of sewage pouring, affecting the normal operation of the aeration pan aeration system, reducing the aeration effect of the aeration pan aeration system, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

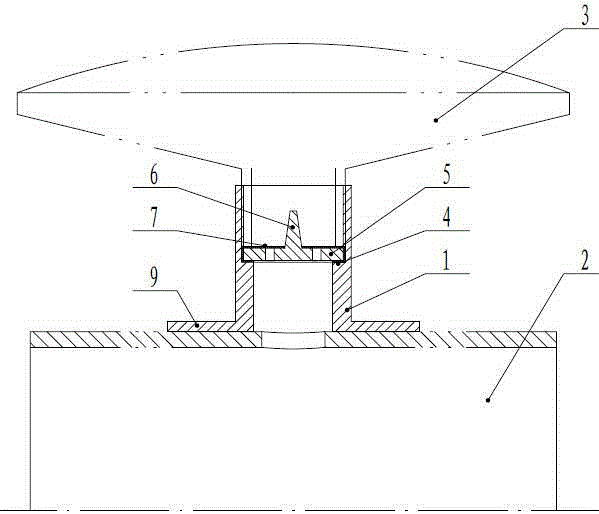

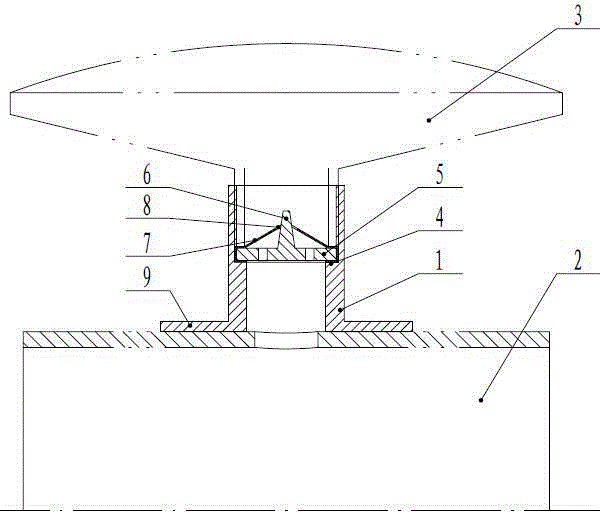

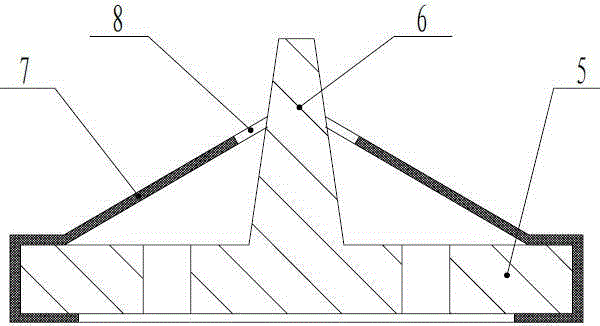

[0025] Such as figure 1 , figure 2 , image 3 As shown, a saddle seat with a backstop device includes a pipe body 1, and the lower end of the pipe body 1 can be fixedly installed on the air delivery pipe 2. In this embodiment, the saddle-shaped seat plate 9 is tightly bonded On the surface of the air delivery pipe 2, the upper end of the pipe body 1 can be fixedly installed with the aeration pan 3, when it is fixedly installed on the air delivery pipe 2, a through hole for ventilation to the pipe body 1 is provided on the air delivery pipe 2 , a backstop device can be fixedly installed in the pipe body 1; the backstop device includes a plate body 5, and a through hole for ventilating the aeration disc 3 and an upwardly protruding cone column 6 are arranged on the plate body 5. The body 5 is covered with an elastic film 7, and the elastic film 7 is provided with a through hole 8 corresponding to the position and shape of the cone column 6, and the periphery of the elastic fi...

Embodiment 2

[0029] Such as Figure 4 As shown, the difference between the second embodiment and the first embodiment is that the compression structure is a short pipe 11, and the aeration pan 3 is also provided with corresponding external threads, and can be installed on the top of the short pipe 11.

Embodiment 3

[0031] Such as Figure 5 As shown, the difference between Embodiment 3 and Embodiment 1 is that the compression structure is a long pipe 12, the upper end of the long pipe 12 is flush with the upper end of the pipe body 1, and the inner hole of the long pipe 12 is also provided with an internal thread. The air disc 3 can be connected with the saddle by the external thread corresponding to the internal thread of the long pipe 12 .

[0032] check valve,

[0033] Such as Figure 6 As shown, a check valve includes a valve body that can be connected to pipelines on both sides, and a check device is fixed in the valve body 10; the check device includes a plate body 5, and a through hole is provided on the plate body 5 And the cone column 6 protruding to one side, the side with the cone column 6 on the plate body 5 is covered with an elastic film 7, and the elastic film 7 is provided with a transparent hole corresponding to the position and shape of the cone column 6. Hole 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com