Imitation wood floor and preparation method thereof

A wood-like floor and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve only 30% of the problems, to achieve the effect of increasing added value, not easy to slip, and reducing site resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

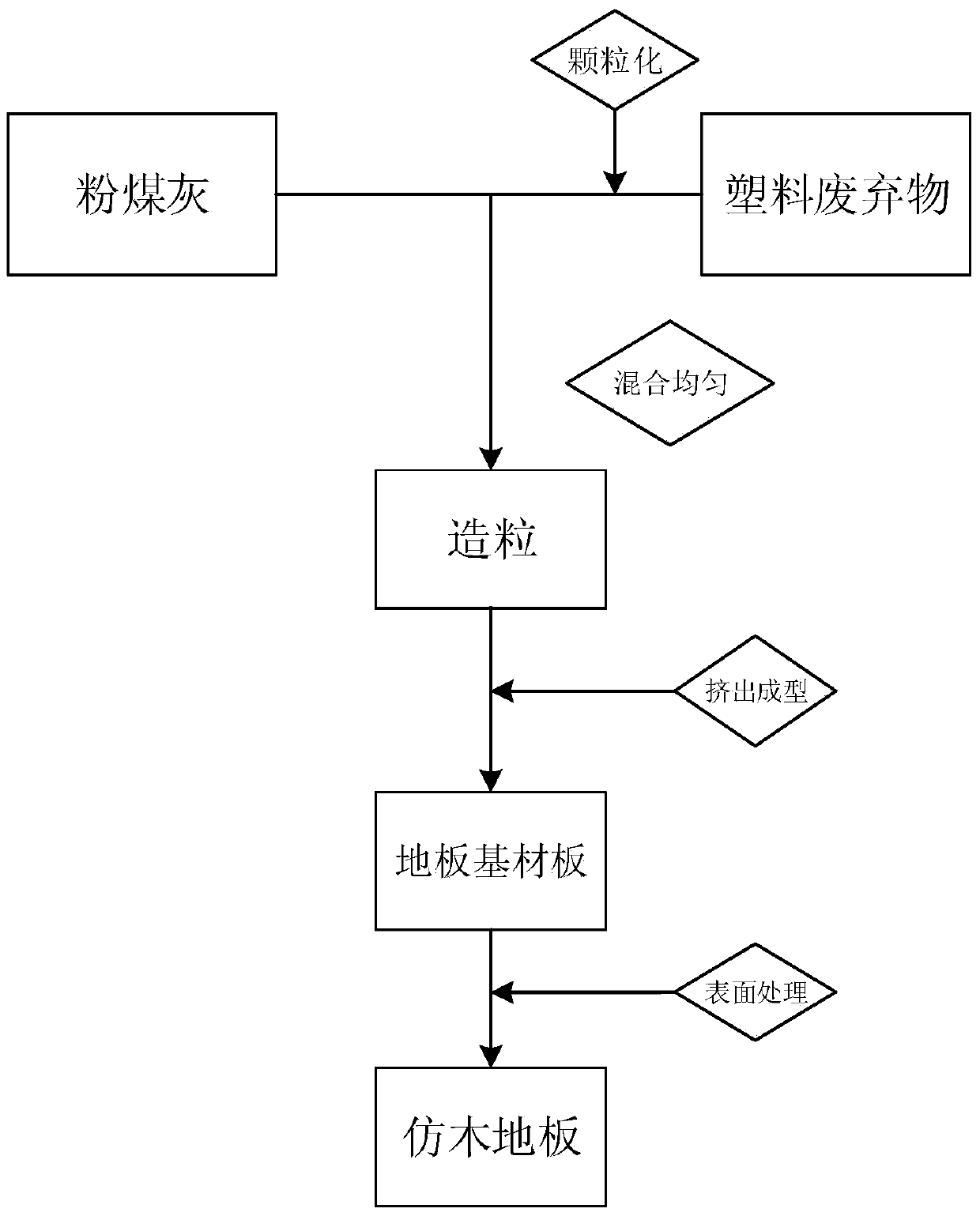

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of imitation wood floor using fly ash and waste plastics

[0026] Put 50 parts of fly ash, 45 parts of plasticized and homogenized waste plastics, 1 part of paraffin wax, 1 part of amino-modified silicone oil, 1 part of stearic acid and 1 part of barium stearate into the mixer and stir for 10 hours. Then dry it in a dryer at 85°C for 10 hours, and then put it into a granulator for granulation to obtain granular materials with a particle size of ≤48 μm. These granular materials are put into the floor molding machine and extruded at a high temperature of 180°C to make a solid floor substrate board ( figure 2 ). The finished floor base board is cooled, cut to length, plugged, grinded, planed, tenoned, finely ground, brushed, high-temperature thermal transfer, UV treatment, hardened and wear-resistant, tested, and packaged. Finished faux wood floors.

Embodiment 2

[0027] Example 2 Preparation of wood-like floor by using fly ash and waste plastics

[0028] Put 65 parts of fly ash, 30 parts of plasticized and homogenized waste plastics, 1 part of paraffin wax, 1 part of amino-modified silicone oil, 1 part of stearic acid and 1 part of barium stearate into the mixer and stir for 10 hours. Then dry it in a dryer at 85°C for 10 hours, and then put it into a granulator for granulation to obtain granular materials with a particle size of ≤48 μm. These granular materials are put into the floor molding machine and extruded at a high temperature of 180°C to make a solid floor substrate board. The finished floor base board is cooled, cut to length, plugged, grinded, planed, tenoned, finely ground, brushed, high-temperature thermal transfer, UV treatment, hardened and wear-resistant, tested, and packaged. Finished faux wood floors.

Embodiment 3

[0029] Example 3 Preparation of wood-like floor by using fly ash and waste plastics

[0030] Put 80 parts of fly ash, 15 parts of plasticized and homogenized waste plastics, 1 part of paraffin wax, 1 part of amino-modified silicone oil, 1 part of stearic acid and 1 part of barium stearate into the mixer and stir for 10 hours. Then dry it in a dryer at 85°C for 10 hours, and then put it into a granulator for granulation to obtain granular materials with a particle size of ≤48 μm. These granular materials are put into the floor molding machine and extruded at a high temperature of 180°C to make a solid floor substrate board. The finished floor base board is cooled, cut to length, plugged, grinded, planed, tenoned, finely ground, brushed, high-temperature thermal transfer, UV treatment, hardened and wear-resistant, tested, and packaged. Finished faux wood floors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com