Ultrasonic wave pulper

An ultrasonic and pulping technology, which is applied in the field of ultrasonic crushing and pulping equipment, can solve the problems of high energy consumption and low efficiency, and achieve the effects of increasing the decomposition speed of crushed materials, preventing vibration damage, and accelerating the efficiency of crushing and pulping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

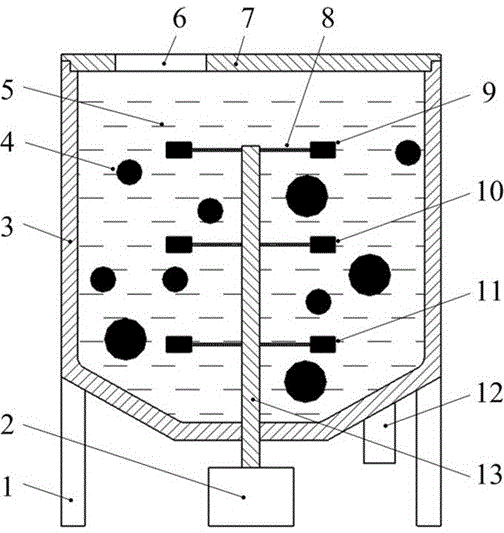

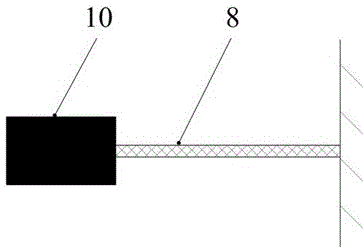

[0014] Such as figure 1 , figure 2 As shown, a kind of ultrasonic disintegrating pulping equipment of the present invention mainly comprises pulper cylinder 3, cylinder cover 7, motor 2, main pipe 13, elastic damping tube 8 and ultrasonic transmitter, and ultrasonic transmitter is divided into the upper zone ultrasonic Transmitter 9, ultrasonic transmitter 10 in the middle area and ultrasonic transmitter 11 in the lower area, the cylinder cover 7 is installed on the pulper barrel 3, the motor 2 is installed at the lower end of the pulper barrel 3, the motor 2 leads the main pipe 13 and extends it Into the pulper barrel 3, the ultrasonic transmitter passes on the main pipe 13.

[0015] The pulper barrel 3 has a cylindrical structure, and the pulper barrel 3 is equipped with water 5 and crushed material 4. The lower end of the pulper barrel 3 is equipped with a discharge port 12 and 4 circumferentially evenly distributed pillars 1; the barrel cover 7 is a round Shaped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com