High earth-rock dam slope protection structure and construction method thereof

A technology of high earth-rock dam and construction method, applied in dams, barrages, coastline protection, etc., can solve problems such as affecting the overall beauty of the dam body, difficult to ensure the flatness of the dam surface, and long construction period, and achieve enhanced resistance to the slope direction. The ability of water scouring, good seismic effect, convenient and fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

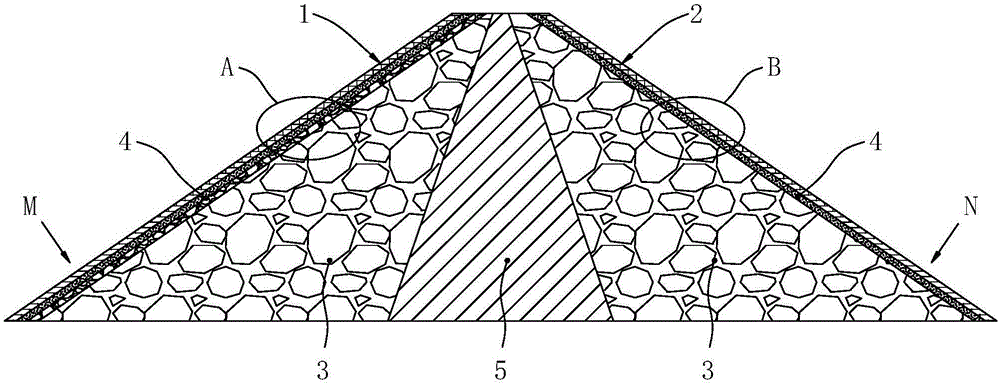

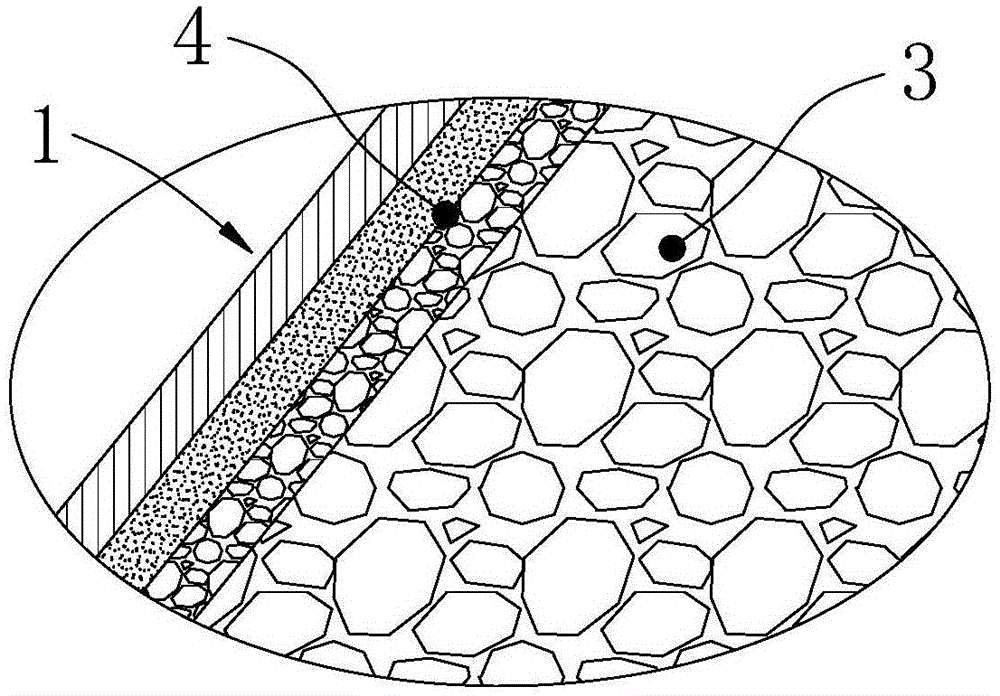

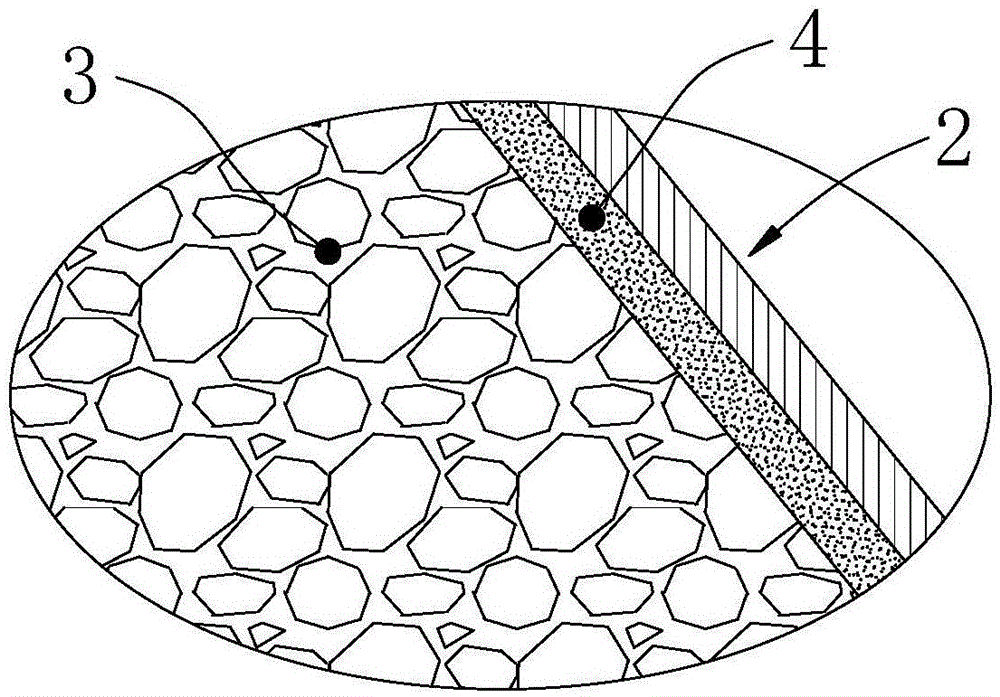

[0039] The height of a core rockfill dam is H=200m, and its slope protection structure includes an upstream dam surface 1 and a downstream dam surface 2 respectively arranged on the upper and downstream surfaces of the rockfill 3 of the dam; the upstream dam surface 1 is mainly composed of multiple pieces The upstream block 11 is built by masonry, the upstream block 11 is a regular hexagonal precast concrete block, the side length of the upstream block 11 is 30cm, the thickness is 20cm, and the center of the upstream block 11 has a diameter of 50mm The drainage hole 111; the downstream dam surface 2 is mainly made of multiple downstream blocks 21, the downstream block 21 is a regular hexagonal prefabricated sand-free concrete block, the side length of the downstream block 21 is 40cm and a thickness of 20cm, the outer surface of the downstream block 21 is provided with an organic humus layer 22 mixed with grass seeds; each block is built with masonry materials; the upstream dam s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com