Temperature control and crack prevention design calculation method for lining concrete with round cross section structure

A technology of temperature control and anti-cracking and calculation method, which is applied in the direction of infrastructure engineering, buildings, artificial waterways, etc., and can solve the problems of man-made coefficient values, time-consuming, expensive, and temperature control standards that cannot be applied to thin-walled lining structures, etc. problem, to achieve the effect of high precision and simple calculation formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings.

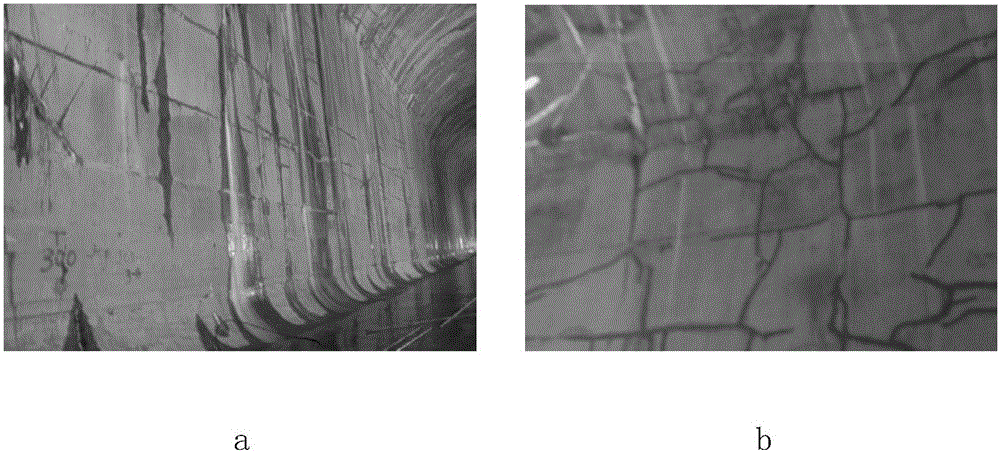

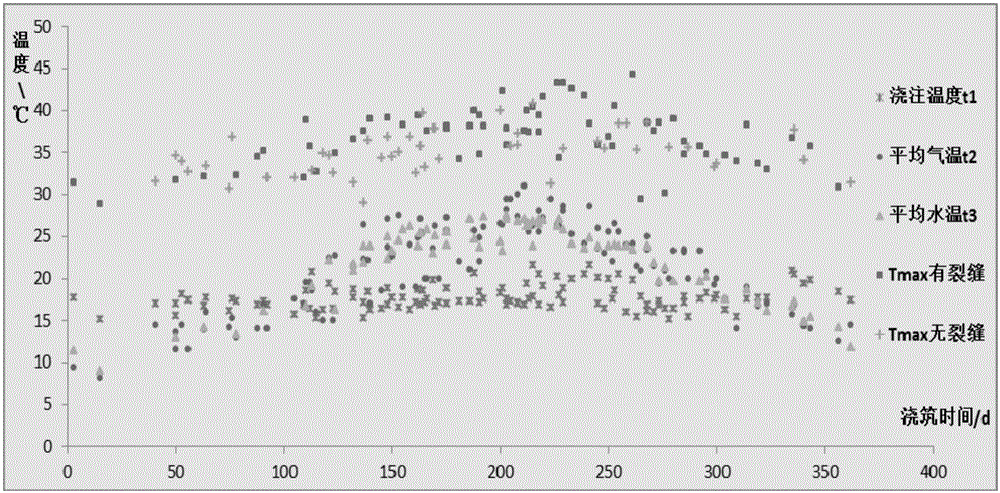

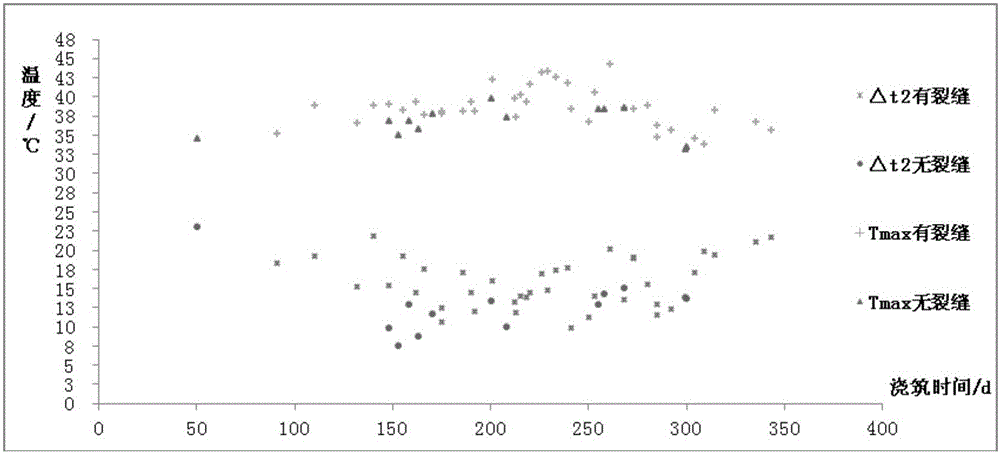

[0063] Taking the concrete temperature control and anti-cracking of the circular section lining concrete in the pressure section of the flood discharge tunnel of a hydropower station as an example.

[0064] 1. Basic information

[0065] A hydropower station is a large (I) project, the spillway is the main building (level I), and the pressure section is a circular section. The properties of the lining and surrounding rock are listed in Table 1. The inner diameter of the lining section is 7.5m ( Figure 5 ), the design strength level of lining concrete is C 90 40. The length of the joint in the structural section is 9m. According to the measured data in the cave at the initial stage of excavation and the data provided by the design institute, the design unit takes the average temperature for many years as 23.5°C and the annual temperature variation as 1.5°C, and calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com